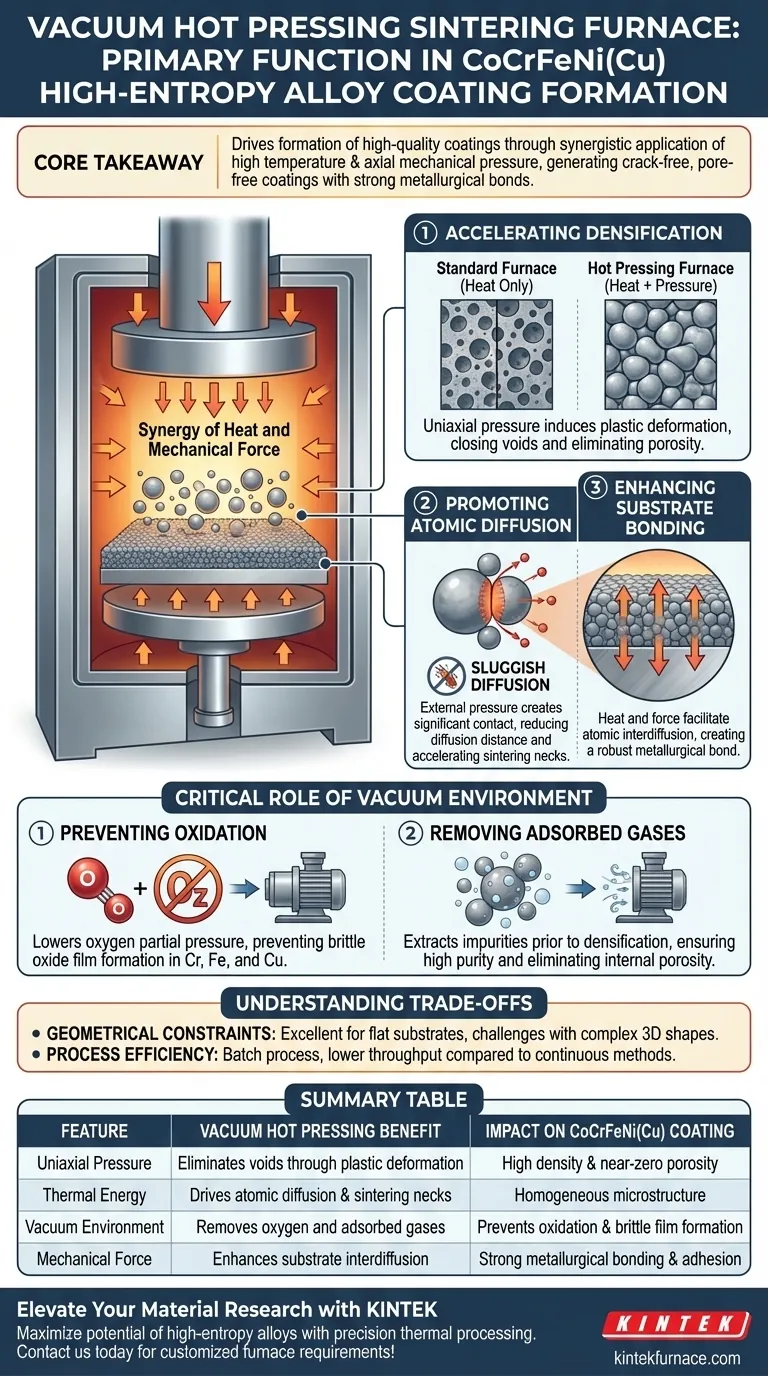

The primary function of a vacuum hot pressing sintering furnace is to drive the formation of high-quality coatings through the synergistic application of high temperature and axial mechanical pressure. By promoting rapid atomic diffusion and plastic deformation in a controlled environment, this process generates crack-free, pore-free CoCrFeNi(Cu) coatings with a strong metallurgical bond to the substrate.

Core Takeaway While conventional sintering relies heavily on time and temperature, vacuum hot pressing introduces mechanical force to physically drive particle coalescence. This approach is critical for high-entropy alloys, as it overcomes their naturally sluggish diffusion rates to produce fully dense, oxidation-free coatings that pressureless methods often fail to achieve.

The Synergy of Heat and Mechanical Force

The defining characteristic of this technology is that it does not rely on thermal energy alone. It combines thermal kinetics with physical mechanics to alter the microstructure of the coating.

Accelerating Densification

In a standard furnace, powder particles densify slowly as they are heated. In a hot pressing furnace, the application of uniaxial pressure (e.g., 50 MPa) physically forces powder particles together. This induces plastic deformation, effectively closing voids and eliminating porosity that heat alone might leave behind.

Promoting Atomic Diffusion

High-entropy alloys like CoCrFeNi(Cu) often exhibit "sluggish diffusion" effects, making them difficult to sinter. The external pressure applied during the process creates significant contact area between particles. This reduces the diffusion distance, accelerating the formation of sintering necks and resulting in a homogeneous, dense structure.

Enhancing Substrate Bonding

The simultaneous application of heat and force does more than just solidify the powder; it acts on the interface between the coating and the substrate. This pressure facilitates atomic interdiffusion at the boundary, creating a robust metallurgical bond rather than a weak mechanical adhesion.

The Critical Role of the Vacuum Environment

The "vacuum" component of the furnace is just as vital as the pressing mechanism, particularly for maintaining the chemical integrity of the alloy.

Preventing Oxidation

CoCrFeNi(Cu) alloys contain elements like Chromium, Iron, and Copper, which are susceptible to oxidation at sintering temperatures (often around 900°C). The high vacuum environment significantly lowers the oxygen partial pressure. This prevents the formation of brittle oxide films that would otherwise compromise the coating's mechanical properties and corrosion resistance.

Removing Adsorbed Gases

Metal powders naturally hold adsorbed gases on their surfaces. If these gases are not removed before the pores close, they become trapped, leading to internal porosity. The vacuum environment extracts these impurities prior to densification, ensuring the final coating maintains high purity.

Understanding the Trade-offs

While vacuum hot pressing offers superior material quality, it is essential to recognize the limitations inherent to the process.

Geometrical Constraints

The pressure applied is typically uniaxial (from one direction). This makes the process excellent for flat substrates or simple geometries but presents challenges for coating complex, non-planar 3D shapes where uniform pressure distribution is difficult to achieve.

Process Efficiency

Compared to continuous sintering methods, vacuum hot pressing is generally a batch process. The requirement to pump down to a high vacuum and the controlled heating and cooling cycles can result in lower throughput and higher operational costs per part.

Making the Right Choice for Your Project

When deciding if vacuum hot pressing is the correct route for your CoCrFeNi(Cu) application, consider your specific performance targets.

- If your primary focus is coating density and hardness: The mechanical pressure provided by this furnace is the most reliable method to eliminate porosity and achieve near-theoretical density.

- If your primary focus is adhesion strength: The metallurgical bonding promoted by the heat-pressure synergy will provide superior resistance to peeling compared to spray coating or pressureless sintering.

- If your primary focus is chemical purity: The vacuum environment is non-negotiable for preventing oxidation in alloys containing reactive elements like Chromium and Iron.

The vacuum hot pressing sintering furnace transforms the coating process from a passive thermal event into an active mechanical consolidation, ensuring the structural integrity required for high-performance applications.

Summary Table:

| Feature | Vacuum Hot Pressing Benefit | Impact on CoCrFeNi(Cu) Coating |

|---|---|---|

| Uniaxial Pressure | Eliminates voids through plastic deformation | High density and near-zero porosity |

| Thermal Energy | Drives atomic diffusion & sintering necks | Homogeneous microstructure |

| Vacuum Environment | Removes oxygen and adsorbed gases | Prevents oxidation and brittle film formation |

| Mechanical Force | Enhances substrate interdiffusion | Strong metallurgical bonding and adhesion |

Elevate Your Material Research with KINTEK

Maximize the potential of your high-entropy alloys with precision thermal processing. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, including specialized vacuum hot pressing solutions. Whether you need a standard laboratory furnace or a fully customizable system for unique coating applications, our equipment ensures the density, purity, and bonding strength your project demands.

Ready to optimize your sintering process? Contact us today to discuss your customized furnace requirements!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a Vacuum Hot Press (VHP) furnace facilitate the fabrication of bulk nanostructured Al-4Cu alloys?

- Why is a Vacuum Hot Pressing Sintering Furnace Essential for 6061-20IQC? Unlock High-Performance Composites

- What is the function of the low-pressure debinding stage in a vacuum hot press? Ensure SiC Fiber Alignment & Integrity

- What is the core function of a flat tablet press in CSP? Achieve High-Pressure Densification for CaF2 Ceramics

- What role does SPS equipment play in half-Heusler fabrication? Mastering Density and Microstructure for Thermoelectrics

- What are the key advantages of vacuum hot press furnaces compared to conventional furnaces? Achieve Superior Purity and Control

- How does the furnace cooling method protect CoCrFeNi(Cu) coatings after vacuum hot pressing sintering? Prevent Cracking & Oxidation for Superior Performance

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing