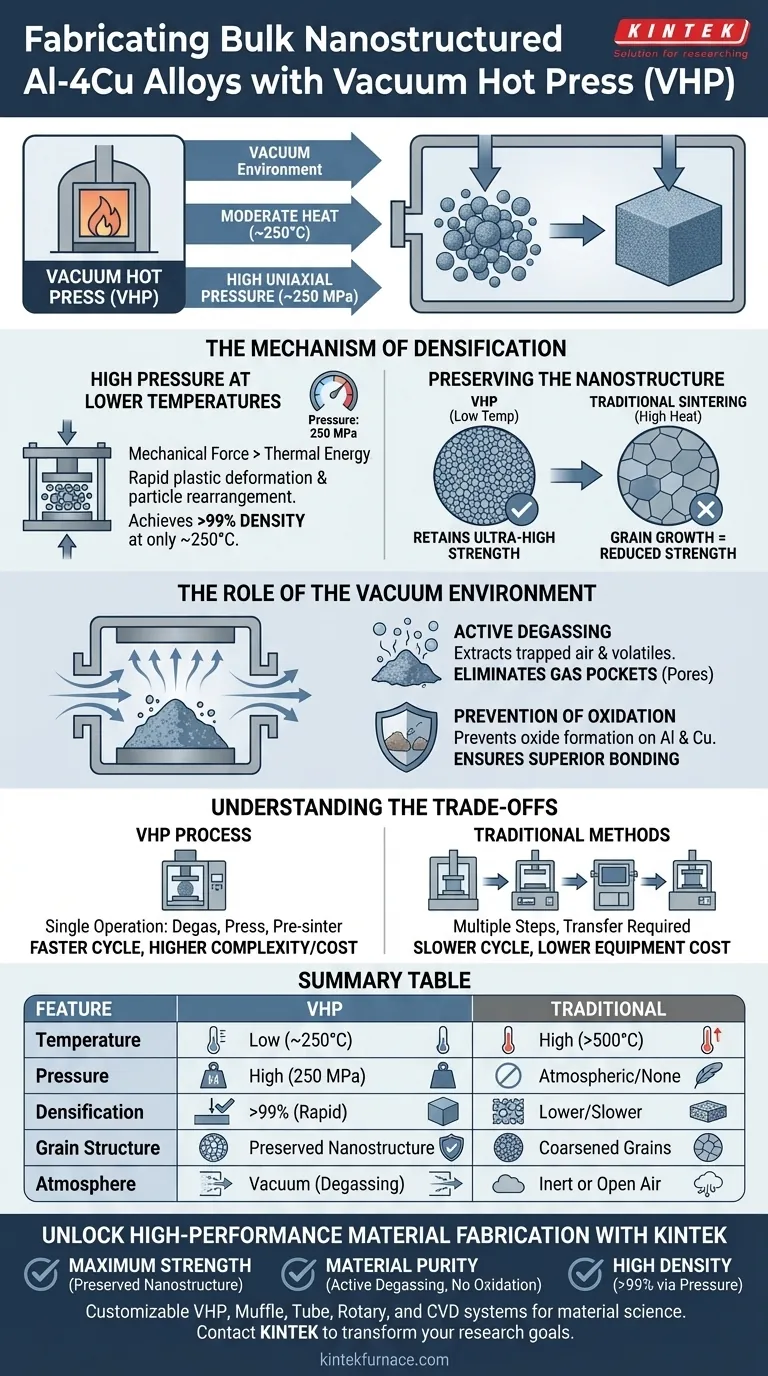

A Vacuum Hot Press (VHP) furnace facilitates the fabrication of bulk nanostructured Al-4Cu alloys by simultaneously subjecting the powder to moderate heating (approximately 250°C) and high uniaxial pressure (around 250 MPa) within a vacuum environment. This dual application forces rapid plastic deformation and particle rearrangement, enabling the material to achieve exceptional densification (over 99%) without requiring the high temperatures that typically destroy nanostructures.

By decoupling densification from high thermal loads, VHP solves the critical engineering conflict between achieving a pore-free solid and preserving the fine grain structure required for ultra-high strength.

The Mechanism of Densification

High Pressure at Lower Temperatures

The defining advantage of VHP for Al-4Cu alloys is the ability to achieve full density at relatively low temperatures.

By applying significant mechanical pressure (e.g., 250 MPa), the furnace mechanically forces powder particles to rearrange and undergo plastic deformation.

This mechanical force substitutes for thermal energy. It drives the elimination of pores through plastic flow and creep mechanisms, allowing the alloy to reach over 99% density at just 250°C.

Preserving the Nanostructure

In traditional sintering, achieving high density usually requires high heat, which causes grains to grow and coarsen.

Coarse grains drastically reduce the strength of the material.

Because VHP achieves densification at low temperatures, it effectively inhibits grain growth. This preserves the nanocrystalline structure, ensuring the final alloy retains its ultra-high strength characteristics.

The Role of the Vacuum Environment

Active Degassing

The vacuum system does more than just provide a clean environment; it actively removes barriers to bonding.

It continuously extracts air trapped in powder gaps and removes volatile impurities released during the heating process.

This degassing action eliminates the gas pockets that would otherwise form pores within the finished body, directly enhancing structural integrity.

Prevention of Oxidation

Aluminum and copper are susceptible to oxidation, which creates brittle boundaries between particles.

The vacuum environment prevents the metal powders from oxidizing during the heating phase.

By maintaining oxide-free surfaces, the furnace ensures superior metallurgical bonding between particles, resulting in higher hardness and compressive strength compared to conventional methods.

Understanding the Trade-offs

Process Efficiency vs. Equipment Complexity

While VHP produces superior material properties, it is important to understand the operational context.

The process integrates three distinct procedures—powder degassing, pressing, and pre-sintering—into a single operation.

This significantly shortens the preparation cycle compared to traditional methods that require transferring samples between machines. However, it requires specialized, complex equipment capable of maintaining high vacuums and pressures simultaneously, which may represent a higher initial resource investment than pressureless sintering.

Making the Right Choice for Your Goal

If you are evaluating fabrication methods for Al-4Cu alloys, consider your specific performance requirements:

- If your primary focus is Maximum Strength: Choose VHP because its low-temperature processing preserves the nanocrystalline grain structure essential for ultra-high strength.

- If your primary focus is Material Purity: Choose VHP for its ability to actively degas the powder and prevent oxidation during the consolidation process.

- If your primary focus is High Density: Choose VHP to leverage mechanical pressure, ensuring >99% densification that pressureless sintering cannot easily achieve.

VHP is the definitive choice when the mechanical integrity of the nanostructure cannot be compromised.

Summary Table:

| Feature | VHP Processing (Al-4Cu) | Traditional Sintering |

|---|---|---|

| Temperature | Low (~250°C) | High (Varies, often >500°C) |

| Pressure | High (250 MPa) | Atmospheric/None |

| Densification | >99% (Rapid) | Lower/Slower |

| Grain Structure | Preserved Nanostructure | Coarsened/Large Grains |

| Atmosphere | Vacuum (Degassing) | Inert or Open Air |

Unlock High-Performance Material Fabrication

Maximize the strength and purity of your Al-4Cu alloys with KINTEK’s precision engineering. Backed by expert R&D and manufacturing, KINTEK offers advanced Vacuum Hot Press (VHP), Muffle, Tube, Rotary, and CVD systems designed for the rigorous demands of material science. Our lab high-temp furnaces are fully customizable to meet your unique densification and grain-size requirements.

Ready to elevate your research or production? Contact KINTEK today to discover how our high-vacuum solutions can transform your nanostructured material goals into reality.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the core function of a flat tablet press in CSP? Achieve High-Pressure Densification for CaF2 Ceramics

- What core role does a vacuum hot press furnace play in the densification process of copper-carbon nanotube composites? Achieve High-Performance Cu-CNT Materials

- Why are Carbon Fiber Reinforced Composite (CFRC) plates used in SPS? Optimize Thermal Stability in Sintering

- What are the mold configuration requirements for sintering non-conductive powders in FAST? Expert Setup Guide

- What is the key principle of a hot press sintering furnace? Achieve Superior Densification for High-Performance Materials

- What function do high-strength graphite molds serve? Essential Roles in Vacuum Hot Pressing Aluminum Matrix Composites

- Why is high-precision temperature control essential for the vacuum hot press furnace? Optimize Ti-Al3Ti Composites

- What are the benefits of the high vacuum environment in a vacuum hot pressing sintering furnace? Gain Maximum Density