High-precision temperature control is the absolute determinant of the reaction mechanism and structural integrity in Ti-Al3Ti laminated composites. It serves as the critical "brake" that prevents the fabrication process from accelerating into an uncontrolled combustion state. Without this precision, the vacuum hot press furnace cannot maintain the narrow processing window required to produce dense, defect-free materials.

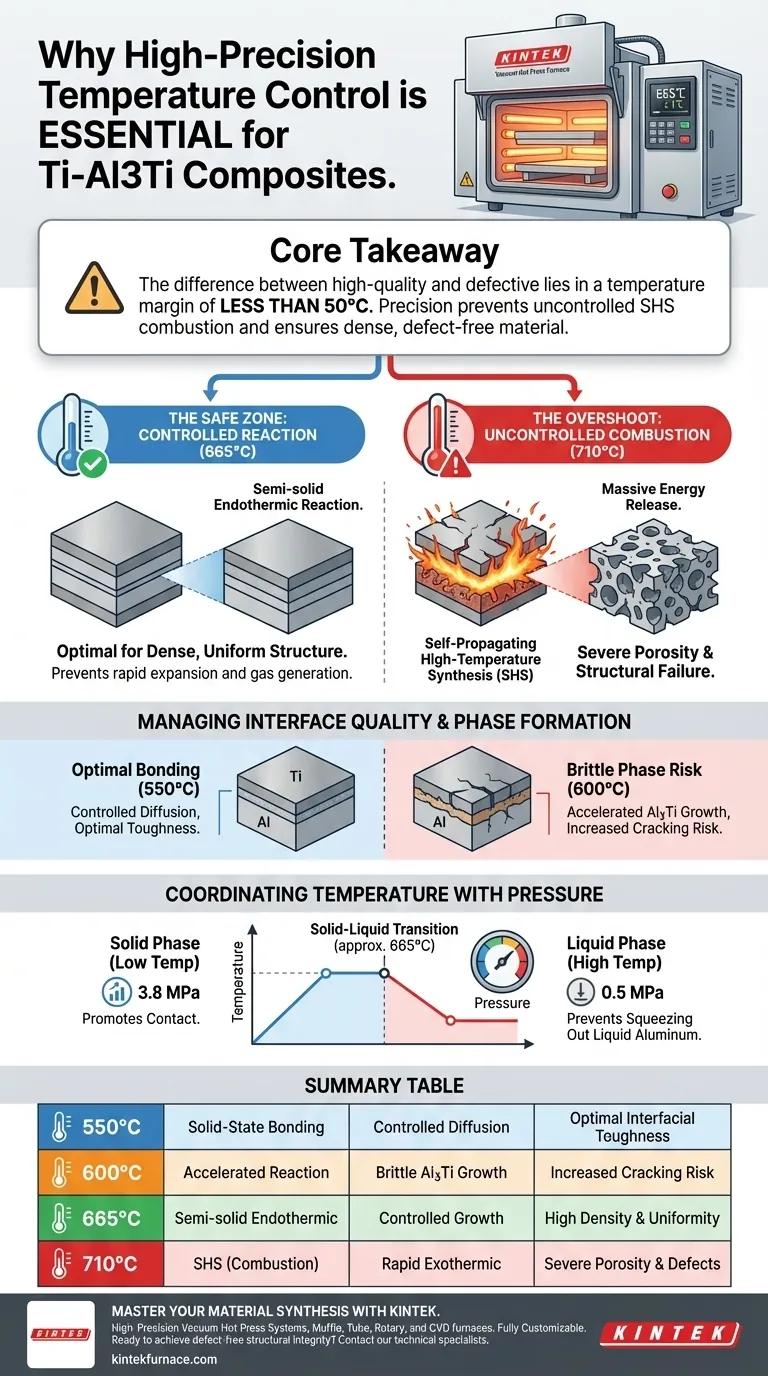

Core Takeaway The difference between a high-quality composite and a defective one often lies in a temperature margin of less than 50°C. Precise thermal regulation allows you to "lock" the process into a controlled semi-solid reaction, preventing the onset of Self-Propagating High-Temperature Synthesis (SHS), which causes severe porosity and structural failure.

The Critical Impact on Reaction Mechanisms

The primary reason for precise control is the volatility of the chemical reaction between Titanium (Ti) and Aluminum (Al) at specific thermal thresholds.

Defining the Safe Zone

Research indicates that a temperature of 665°C is the optimal set point for preparing these composites.

At this specific temperature, the materials undergo a semi-solid endothermic reaction. This controlled reaction path promotes the formation of a dense, uniform structure without rapid expansion or gas generation.

The Consequences of Overshoot

If the furnace temperature drifts higher to just 710°C, the physics of the process change drastically.

This slightly higher temperature triggers a Self-Propagating High-Temperature Synthesis (SHS) combustion reaction. Unlike the controlled endothermic reaction, SHS releases massive amounts of energy.

This rapid reaction leads to significant porosity defects within the material. The precision of the equipment is the only safeguard against accidentally crossing this threshold and degrading the material's performance.

Managing Interface Quality and Phase Formation

Beyond the primary reaction mechanism, temperature precision dictates the microscopic quality of the bonding interface.

Controlling Diffusion Layer Thickness

Temperature directly regulates the rate of atomic diffusion between the metal layers.

Precise control ensures the interface diffusion layer reaches the optimal thickness for bonding without becoming excessive.

Avoiding Brittle Intermetallic Phases

Specific lower temperature ranges, such as 550°C, are often optimal for initial bonding.

However, if the temperature fluctuates upward to 600°C unintentionally, it can accelerate the formation of brittle Al3Ti intermetallic compounds.

Excessive formation of these compounds at the interface leads to cracks and a significant reduction in the composite's plasticity.

Coordinating Temperature with Pressure

High-precision temperature control is not just about heat; it is the trigger for adjusting mechanical pressure within the vacuum hot press furnace.

Identifying the Phase Transition

The process involves a shift from solid-solid diffusion to solid-liquid reactions.

Operators must know exactly when the aluminum begins to melt to adjust the furnace pressure.

Preventing Stoichiometric Errors

In the low-temperature solid phase, high pressure (e.g., 3.8 MPa) is required to promote contact.

However, once the temperature exceeds 665°C, pressure must be drastically reduced (e.g., to 0.5 MPa).

If temperature control is inaccurate, you risk maintaining high pressure on liquid aluminum. This squeezes the liquid out of the layered structure, ruining the reaction stoichiometry and the final composition.

Common Pitfalls of Thermal Instability

When evaluating furnace capabilities, it is essential to understand the trade-offs of insufficient precision.

- Porosity: A lack of precision leads to "overshoot," triggering combustion reactions that fill the composite with voids.

- Embrittlement: Thermal fluctuations can grow the intermetallic layer too thick, causing the material to fracture under stress.

- Material Loss: If the temperature sensor lags, the aluminum may melt before the pressure is reduced, physically forcing essential material out of the die.

Making the Right Choice for Your Goal

To ensure the successful fabrication of Ti-Al3Ti composites, apply these principles to your processing strategy:

- If your primary focus is Structural Density: Prioritize stability around 665°C to force a semi-solid endothermic reaction and strictly avoid the 710°C SHS threshold.

- If your primary focus is Interfacial Toughness: Maintain lower temperatures (near 550°C) during the bonding stage to prevent the rapid growth of brittle Al3Ti phases.

- If your primary focus is Compositional Accuracy: Ensure temperature monitoring is synchronized with pressure controls to drop mechanical force the moment the liquid phase appears.

Ultimately, high-precision temperature control acts as the gatekeeper, ensuring the energy input creates a dense metallurgical bond rather than a porous combustion defect.

Summary Table:

| Temperature | Reaction Type | Outcome | Structural Impact |

|---|---|---|---|

| 550°C | Solid-State Bonding | Controlled Diffusion | Optimal Interfacial Toughness |

| 600°C | Accelerated Reaction | Brittle Al3Ti Growth | Increased Cracking Risk |

| 665°C | Semi-solid Endothermic | Controlled Growth | High Density & Uniformity |

| 710°C | SHS (Combustion) | Rapid Exothermic | Severe Porosity & Defects |

Master Your Material Synthesis with KINTEK

Precise thermal management is the difference between a high-performance Ti-Al3Ti composite and a failed batch. At KINTEK, we understand that a margin of 50°C changes everything.

Backed by expert R&D and world-class manufacturing, we provide high-precision Vacuum Hot Press Systems, Muffle, Tube, Rotary, and CVD furnaces specifically designed to maintain the narrow processing windows required for advanced materials. Whether you need to avoid SHS combustion or precisely control interfacial diffusion, our equipment is fully customizable to your unique research and production needs.

Ready to achieve defect-free structural integrity?

Contact our technical specialists today to find the perfect high-temperature solution for your lab.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum hot press sintering furnace densify SiC ceramics? Achieve Near-Theoretical Density with KINTEK

- How does the uniaxial pressure applied by a vacuum hot press furnace affect the microstructure of ZrC-SiC materials?

- How are vacuum hot pressing sintering furnaces classified based on their operating temperature? A Guide to Low, Medium, and High-Temp Ranges

- Why is high temperature control precision essential in a vacuum hot pressing sintering furnace? Ensure Material Density

- How does the vacuum press contribute to material property improvement? Achieve Denser, Purer Materials for Superior Performance

- What are the advantages of using hot press sintering equipment? Optimize SiC/Cu-Al2O3 Composite Performance

- What is hot pressing sintering and how does vacuum hot pressing sintering improve the process? Achieve Superior Material Density and Purity

- Why is adjustable temperature important in a vacuum hot press furnace? Unlock Precision for Superior Materials Processing