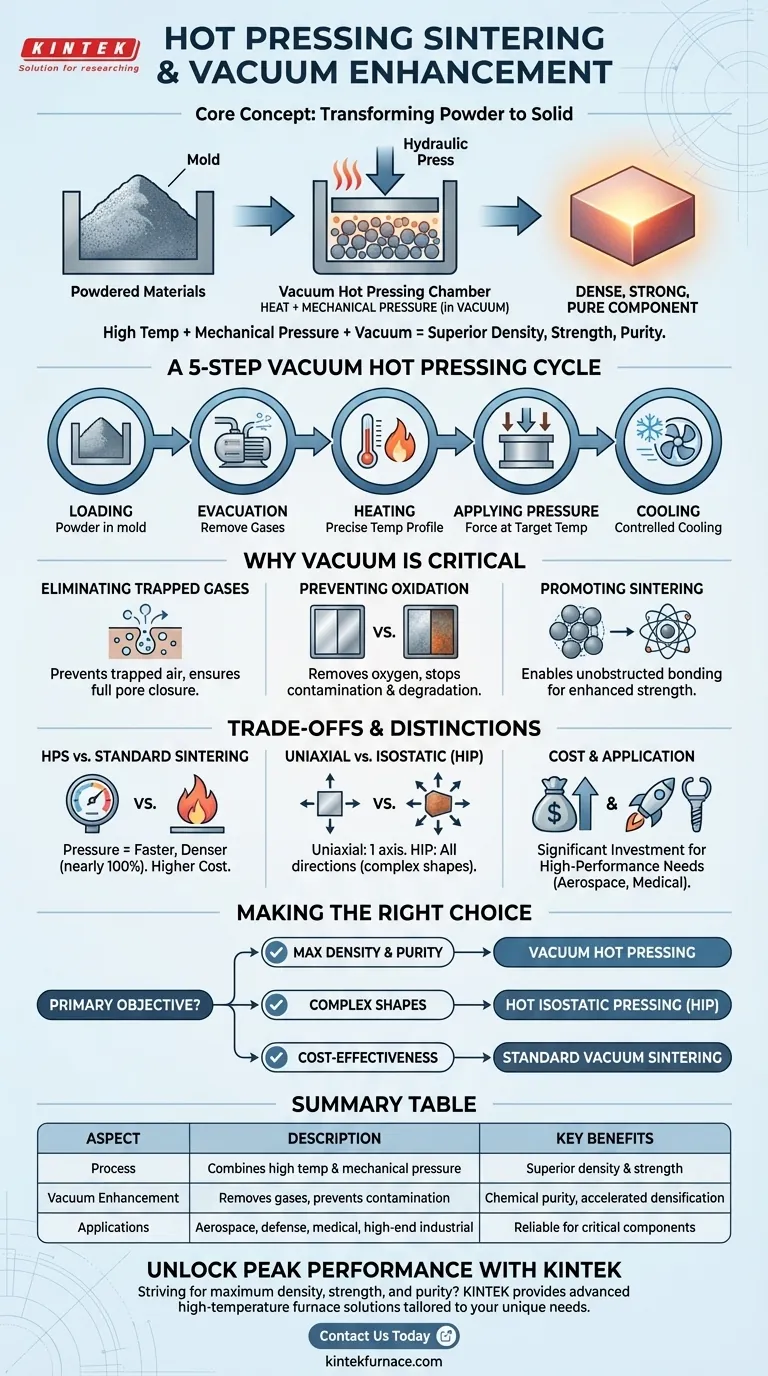

At its core, hot pressing sintering is a manufacturing process that uses a combination of high temperature and mechanical pressure to transform powdered materials into a solid, dense object. The addition of a vacuum environment significantly enhances this process. By removing air and other gases, vacuum hot pressing prevents chemical contamination and eliminates residual porosity, resulting in a final component with superior density, strength, and purity.

The fundamental advantage of vacuum hot pressing is its dual-action approach: mechanical pressure physically forces powder particles together to close pores, while the vacuum environment ensures these pores are empty and prevents unwanted reactions, enabling the creation of materials that are as close to theoretically perfect density as possible.

The Mechanics of Hot Pressing Sintering

Combining Heat and Pressure

Hot pressing works by simultaneously applying thermal energy (heat) and mechanical energy (pressure). Heat gives the atoms within the powder particles enough mobility to diffuse and bond with neighboring particles.

Simultaneously, external pressure forces the particles together, collapsing the empty spaces (pores) between them. This powerful combination accelerates densification far beyond what is possible with heat alone.

A Step-by-Step Process

The typical vacuum hot pressing cycle is a carefully controlled sequence of events designed to achieve a specific material outcome.

- Loading: The powdered material is placed into a mold, which is then loaded into the furnace.

- Evacuation: The furnace chamber is sealed, and powerful pumps create a high-vacuum environment, removing air and other gases.

- Heating: The material is heated according to a precise temperature profile.

- Applying Pressure: Once at the target temperature, a hydraulic press applies force to the material for a set duration.

- Cooling: After the pressing stage, the component is cooled down in a controlled manner to prevent thermal shock and ensure a stable microstructure.

Why Vacuum is the Critical Enhancement

Eliminating Trapped Gases

The primary role of the vacuum is to remove the air trapped between the powder particles before heating begins. If this air were present, it would be compressed into the remaining pores during pressing.

This trapped gas prevents the pores from fully closing, resulting in a less dense final product with compromised mechanical properties.

Preventing Oxidation and Contamination

Many high-performance materials, especially metals and certain ceramics, are highly reactive with oxygen at sintering temperatures. A vacuum environment removes this oxygen.

This prevents the formation of undesirable oxides and other contaminants that can degrade the material's strength, conductivity, or other critical properties. The result is a chemically purer component.

Promoting Sintering Reactions

By creating an ultra-clean, gas-free environment, the fundamental sintering mechanisms—like atomic diffusion and grain boundary growth—can proceed without obstruction.

This leads to more effective bonding between particles, directly translating to enhanced material strength, toughness, and overall performance as noted in finished part analysis.

Understanding the Trade-offs and Distinctions

Hot Pressing vs. Standard Sintering

The key difference is pressure. Standard sintering relies only on heat to densify a powder compact, a process that can be slow and may not achieve full density.

Hot pressing adds mechanical force, dramatically speeding up the process and enabling densities that are nearly 100% of the theoretical maximum. This performance comes at the cost of more complex and expensive equipment.

Uniaxial vs. Isostatic Pressing

Standard hot pressing is typically uniaxial, meaning pressure is applied along a single axis (e.g., from top to bottom).

A related process, Hot Isostatic Pressing (HIP), places the component in a high-pressure inert gas environment, applying pressure equally from all directions. HIP is ideal for complex shapes but is often an even more complex process.

Cost and Application

Vacuum hot pressing machinery is a significant investment. The process is therefore reserved for applications where the ultimate in material performance is required and the cost is justified.

This includes components for the aerospace, defense, medical, and high-end industrial sectors, where material failure is not an option.

Making the Right Choice for Your Goal

Selecting the correct densification method requires a clear understanding of your project's primary objective.

- If your primary focus is maximum density and material purity: Vacuum hot pressing is the superior choice, as it actively removes internal voids and prevents chemical contamination.

- If your primary focus is uniform densification of complex shapes: Hot Isostatic Pressing (HIP) is likely a better alternative, as its gas-based pressure acts evenly on all surfaces.

- If your primary focus is cost-effectiveness for less critical parts: Standard vacuum sintering (without external pressure) can achieve excellent results for many materials and is a simpler, more economical process.

Ultimately, understanding these principles allows you to choose the manufacturing path that best aligns with your material, geometric, and performance requirements.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Combines high temperature and mechanical pressure to densify powdered materials. |

| Vacuum Enhancement | Removes gases to prevent contamination and eliminate porosity, improving density and purity. |

| Key Benefits | Superior density, enhanced strength, chemical purity, and accelerated densification. |

| Applications | Aerospace, defense, medical, and high-end industrial components. |

Unlock Peak Performance for Your Materials with KINTEK

Are you striving for maximum density, strength, and purity in your high-performance components? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your experimental and production requirements.

Don't let material limitations hold you back—contact us today to discuss how our vacuum hot pressing technologies can elevate your projects and deliver reliable, high-quality results for critical applications in aerospace, defense, medical, and beyond.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure