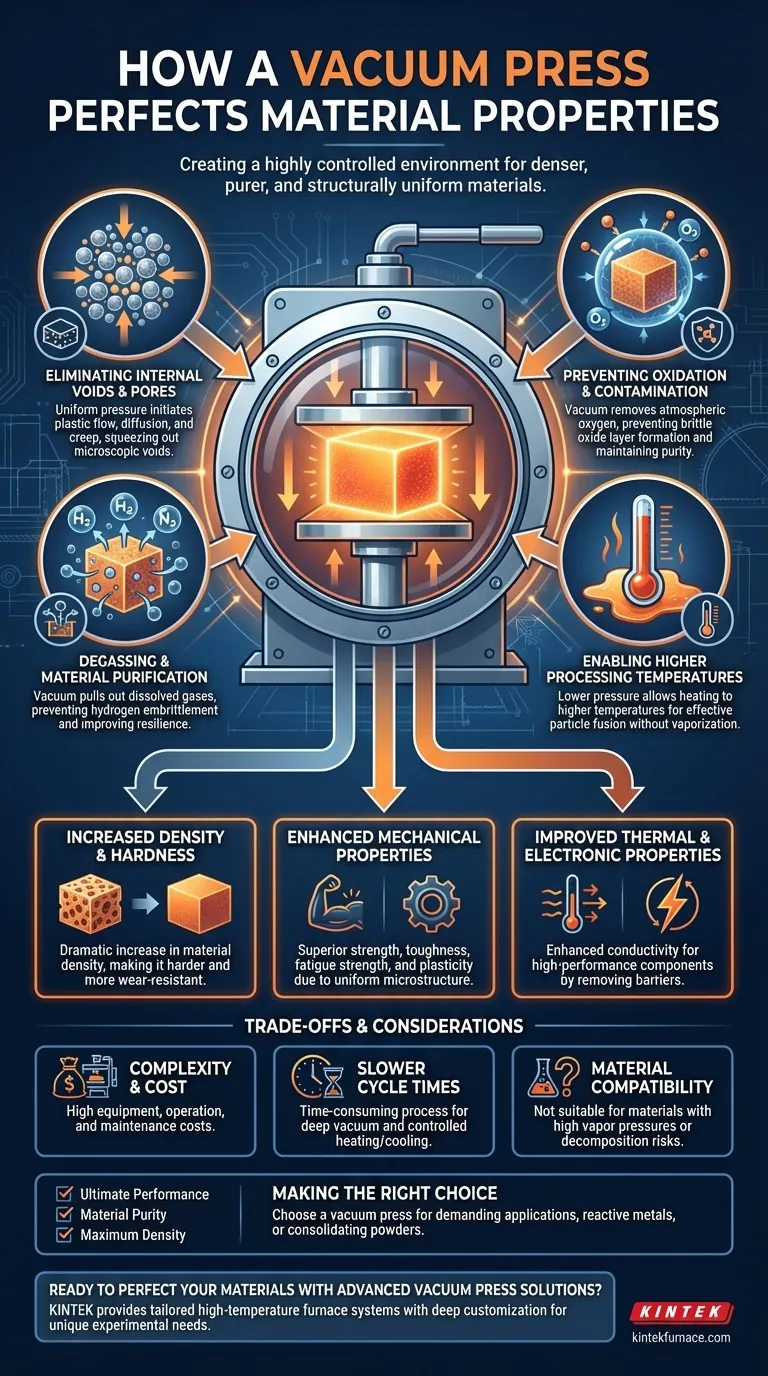

In essence, a vacuum press improves material properties by creating a highly controlled environment where heat and pressure can work more effectively. This process simultaneously eliminates internal defects like pores and prevents contamination from the atmosphere, resulting in a denser, purer, and structurally uniform final product with enhanced mechanical, thermal, and electronic characteristics.

The critical insight is that the vacuum is not merely an empty space; it is an active component of the process. It purifies the material by removing gases and preventing oxidation, enabling the applied pressure and heat to achieve a level of densification and structural integrity that is impossible in a standard atmosphere.

The Core Mechanisms: How Vacuum and Pressure Transform Materials

To understand the benefits, we must first examine the distinct roles that the vacuum environment and the physical pressure play. They work in concert to fundamentally re-engineer the material from the inside out.

Eliminating Internal Voids and Pores

At high temperatures, materials become more malleable. The immense, uniform pressure applied by the press initiates plastic flow, diffusion, and creep.

These mechanisms force material to move into empty spaces, physically squeezing out the microscopic voids and pores that are inherent weaknesses in many raw or partially processed materials.

Preventing Oxidation and Contamination

Many advanced materials, especially metals and certain ceramics, readily react with oxygen at high temperatures. This forms brittle oxide layers that compromise integrity.

A vacuum environment removes atmospheric oxygen, preventing these detrimental reactions. This ensures the material's surface and internal chemistry remain pure, which is critical for properties like strength and conductivity.

Degassing and Material Purification

Beyond preventing new contamination, the vacuum actively cleanses the material. It pulls dissolved gases, particularly harmful ones like hydrogen, out from within the material's structure.

Removing hydrogen prevents a phenomenon known as hydrogen embrittlement, which can severely reduce a metal's toughness and plasticity. This degassing step results in a more resilient and reliable material.

Enabling Higher Processing Temperatures

Under normal atmospheric pressure, some materials would vaporize or "boil" before reaching the ideal temperature for sintering or densification.

By dramatically lowering the pressure, a vacuum allows these materials to be heated to much higher temperatures. This enables them to soften or slightly melt, allowing the applied pressure to fuse particles together far more effectively.

The Result: Measurable Improvements in Material Properties

The combination of these mechanisms leads to tangible and significant enhancements across a spectrum of material characteristics.

Increased Density and Hardness

The most direct outcome of eliminating pores is a dramatic increase in material density. A denser material is inherently harder and more resistant to wear and abrasion, as there are fewer weak points to initiate fracture or deformation.

Enhanced Mechanical Properties

A uniform microstructure, free from voids and oxide inclusions, has superior mechanical strength. This translates to improved toughness, fatigue strength, and plasticity. The final component can withstand greater stress and strain before failing.

Improved Thermal and Electronic Properties

Voids and impurities act as barriers to the flow of heat and electricity. By creating a denser, purer, and more uniform material, a vacuum press enhances thermal and electrical conductivity, making it ideal for high-performance electronic components or heat management applications.

Understanding the Trade-offs and Considerations

While powerful, the vacuum hot press process is not a universal solution. It involves specific trade-offs that must be weighed against its benefits.

Process Complexity and Cost

Vacuum hot press systems are significantly more complex and expensive to acquire, operate, and maintain than conventional atmospheric furnaces. The need for robust vacuum pumps, seals, and control systems adds to the overhead.

Slower Cycle Times

Achieving a deep vacuum, heating the chamber, applying pressure, and cooling down under controlled conditions is a time-consuming process. For high-volume manufacturing of less critical parts, the cycle time can be a significant drawback.

Material Compatibility

While versatile, the process is not suitable for all materials. Materials with high vapor pressures or components that can decompose under vacuum may not be appropriate candidates for this type of processing.

Making the Right Choice for Your Goal

The decision to use a vacuum press hinges on the required performance level of the final component.

- If your primary focus is ultimate performance and reliability: Use a vacuum press to eliminate the microscopic defects that are the starting points for material failure in demanding applications like aerospace or medical implants.

- If your primary focus is material purity: Use a vacuum press for processing reactive metals (like titanium) or for electronic materials where even minor oxidation would degrade performance.

- If your primary focus is achieving maximum density: Use a vacuum press for consolidating powdered metals, composites, or ceramics into a solid, non-porous form that is impossible to achieve otherwise.

Ultimately, choosing to use a vacuum press is a deliberate engineering decision to create materials that are not just formed, but fundamentally perfected.

Summary Table:

| Mechanism | Key Benefit |

|---|---|

| Eliminates voids and pores | Increases density and hardness |

| Prevents oxidation and contamination | Enhances purity and mechanical strength |

| Degasses materials | Improves toughness and reliability |

| Enables higher processing temperatures | Boosts thermal and electrical conductivity |

Ready to perfect your materials with advanced vacuum press solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace systems. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to enhance your material properties and achieve superior performance in your applications!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing