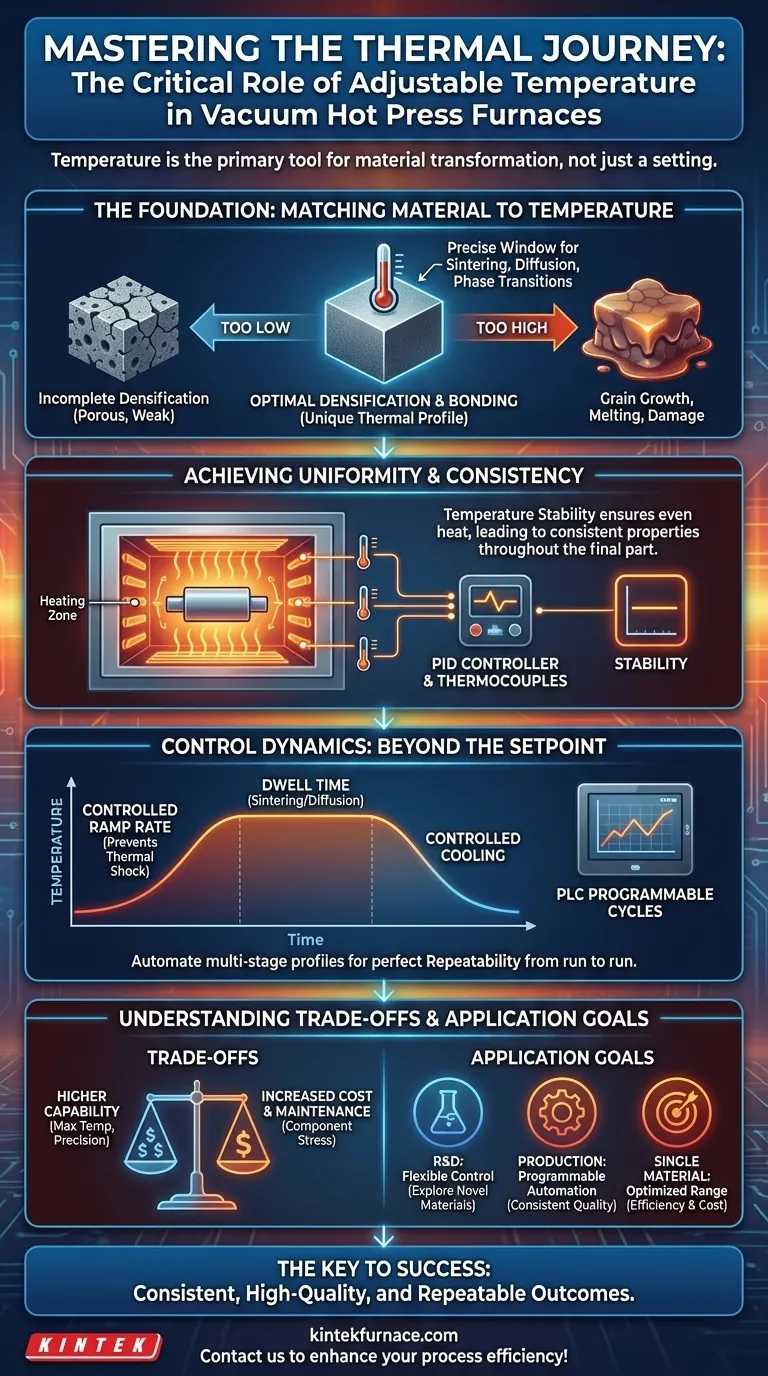

In materials processing, temperature is not just a setting; it is the primary tool for transformation. Adjustable temperature control is essential in a vacuum hot press furnace because every material possesses a unique thermal profile required for optimal densification, bonding, and structural integrity. The ability to precisely set, control the rate of change, and hold a specific temperature ensures that the process is perfectly matched to the material's requirements, leading to consistent, high-quality, and repeatable outcomes.

The true importance of adjustable temperature lies not just in reaching a specific heat, but in commanding the entire thermal journey. Control over the heating rate, stability at the target temperature, and the cooling phase is what separates successful material consolidation from component failure.

The Foundation: Matching Temperature to Material

A vacuum hot press works by applying heat and pressure simultaneously to form a dense, solid material from a powder or preform. Temperature is the catalyst for the physical and chemical changes that make this possible.

Why Every Material Has a Unique Thermal Profile

Different materials, from advanced ceramics to metal alloys and composites, have distinct temperature windows where critical processes like sintering, diffusion bonding, or phase transitions occur.

Applying a temperature that is too low will result in incomplete densification, leaving a porous and mechanically weak product. Conversely, a temperature that is too high can cause grain growth, melting, or decomposition, permanently damaging the material's microstructure and properties.

Achieving Uniformity and Consistency

The goal of hot pressing is a uniform result. Temperature stability, or the ability to hold a setpoint with minimal deviation, is crucial for this.

A control system using thermocouples for measurement and PID (Proportional-Integral-Derivative) controllers ensures the heat supplied to the heating zone is precisely managed. This stability guarantees that the entire component experiences the same thermal conditions, leading to consistent properties throughout the final part.

Beyond the Setpoint: The Importance of Control Dynamics

Advanced temperature control involves more than just selecting a final temperature. The path taken to reach that temperature is equally critical for success, especially with sensitive or complex materials.

Controlling the Ramp Rate

The ramp rate is the speed at which the furnace's temperature increases. A controlled ramp rate is vital for preventing thermal shock, where rapid, uneven heating can cause cracks to form in the material, especially in brittle ceramics.

Adjusting this rate allows the component to heat uniformly, minimizing internal stresses and ensuring structural integrity before the pressing phase even begins.

The Role of Programmable Cycles

Modern furnaces utilize PLC (Programmable Logic Controller) or touchscreen controls to automate the entire thermal profile.

This allows an operator to program a multi-stage cycle with specific ramp rates, dwell times (the period spent at a constant temperature), and controlled cooling rates. This level of automation is the key to achieving perfect repeatability from one production run to the next.

Understanding the Trade-offs and System Limitations

While sophisticated temperature control is a clear advantage, it's important to understand the associated technical and financial considerations.

Maximum Temperature vs. Application Needs

Furnaces are available with maximum operating temperatures up to 2200°C, but higher capability comes at a cost. The heating elements, insulation, and power systems required for extreme temperatures are significantly more expensive.

It is more practical to select a furnace whose maximum temperature comfortably exceeds the requirements of your primary materials, rather than paying for a capacity you will never use.

Control Precision and Equipment Cost

The level of control sophistication directly impacts the equipment's price. A simple PID controller is standard, but a fully programmable PLC system for complex, multi-stage cycles represents a larger investment.

The choice depends on the complexity of your processes and the need for automation and data logging for quality control.

Impact on Component Lifespan

Consistently operating the furnace at its maximum temperature or using very aggressive ramp rates places significant stress on core components like heating elements and thermocouples.

This can shorten their operational life and increase maintenance costs. A well-designed thermal cycle balances process efficiency with the long-term health of the furnace.

Applying Temperature Control to Your Goal

The level of temperature adjustability you need is directly tied to your end goal. When evaluating a system or designing a process, consider what you are trying to achieve.

- If your primary focus is research and development: Prioritize a system with highly flexible control over ramp rates and precise temperature stability to explore the processing windows of novel materials.

- If your primary focus is production and repeatability: Emphasize a system with robust, programmable controls (like PLC) to ensure every cycle is identical, guaranteeing consistent product quality.

- If your primary focus is processing a single, well-defined material: You can select a furnace optimized for that material's temperature range, potentially reducing initial cost and operational complexity.

Ultimately, mastering the thermal profile of your furnace is the key to unlocking the full potential of your materials.

Summary Table:

| Aspect | Key Points |

|---|---|

| Material Matching | Unique thermal profiles for sintering, bonding, and phase transitions; prevents defects like porosity or grain growth. |

| Uniformity & Consistency | Temperature stability via PID controllers and thermocouples ensures even heating and consistent part properties. |

| Control Dynamics | Adjustable ramp rates prevent thermal shock; programmable cycles with PLCs enable repeatable multi-stage processes. |

| Application Goals | R&D needs flexible control; production requires automation; single-material processes benefit from optimized ranges. |

| Trade-offs | Higher max temperatures and advanced controls increase costs; aggressive cycles can shorten component lifespan. |

Ready to master temperature control for your materials? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your process efficiency and achieve consistent, high-quality results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What is a vacuum hot press furnace? Unlock Superior Material Performance