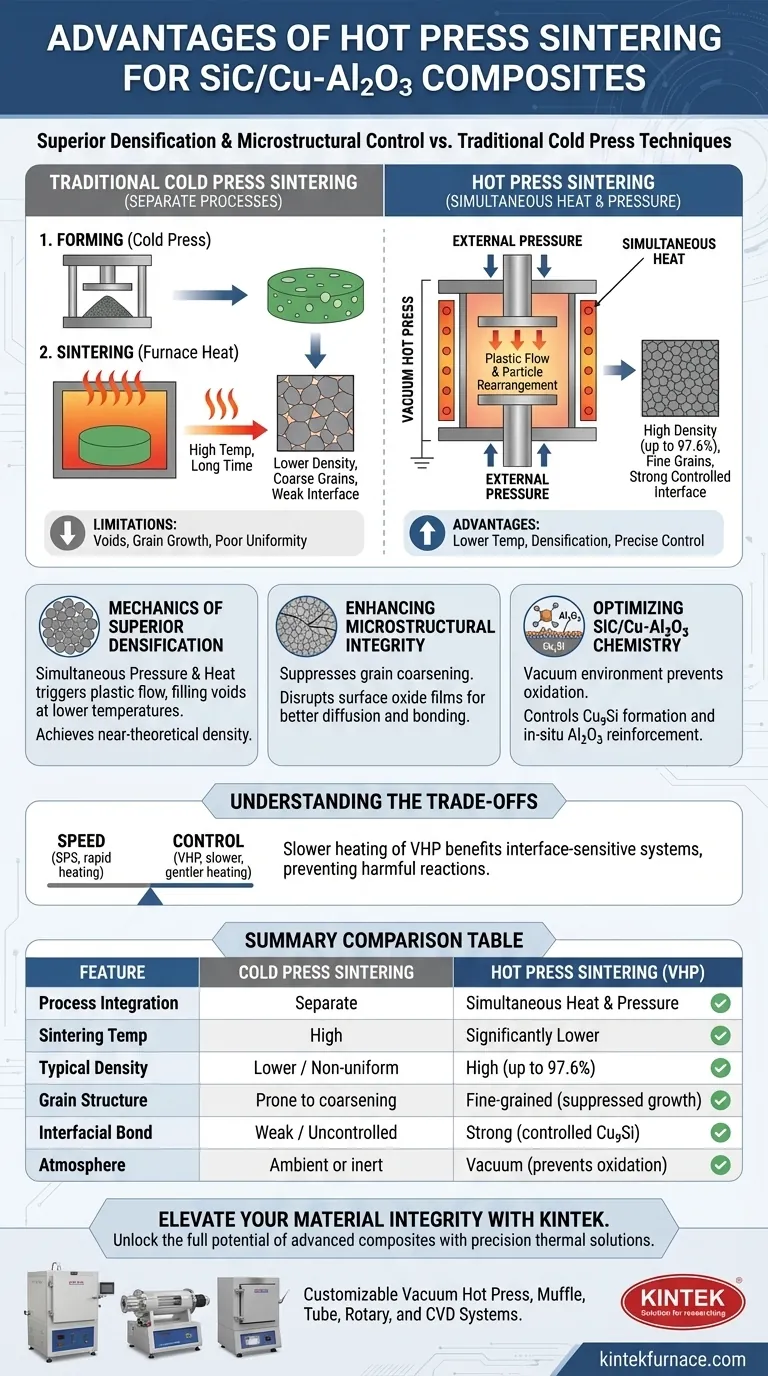

Hot press sintering equipment fundamentally outperforms traditional cold press techniques by integrating the forming and sintering stages into a single, pressure-assisted process. This simultaneous application of heat and external pressure allows you to achieve significantly denser structures with finer grain sizes, all while utilizing lower forming pressures and sintering temperatures than would be required to achieve comparable results with cold pressing.

By applying mechanical pressure during the heating phase, hot press sintering facilitates plastic flow and particle rearrangement that cold pressing cannot replicate. This results in superior material density and structural uniformity while enabling precise control over interfacial reactions critical for high-performance SiC/Cu-Al2O3 composites.

The Mechanics of Superior Densification

Simultaneous Pressure and Heating

Unlike cold pressing, which separates forming and sintering, hot press equipment applies external pressure while the material is hot.

This combination triggers local plastic flow and diffusion creep caused by grain boundary sliding.

Eliminating Voids at Lower Temperatures

The mechanical pressure forces the rearrangement of powder particles, effectively filling voids that simple thermal sintering might miss.

This mechanism allows the material to eliminate pores and achieve high densities (up to 97.6%) at temperatures significantly lower than those required for pressureless sintering.

Overcoming Cold Press Limitations

Traditional cold press sintering often suffers from poor structural uniformity and lower density unless extremely high pressures are used.

Hot press sintering effectively overcomes these drawbacks by using heat to soften the material during compression, ensuring a consistent, dense structure throughout the composite.

Enhancing Microstructural Integrity

Suppression of Grain Coarsening

High temperatures required in traditional sintering often lead to grain coarsening, which weakens the material.

Pressure-assisted sintering allows for densification at lower temperatures, which effectively suppresses grain coarsening and maintains a fine-grained microstructure.

Disruption of Oxide Films

For composites involving aluminum, surface oxide films can hinder bonding.

The simultaneous application of axial pressure disrupts these surface oxide films on the powders, accelerating material diffusion and ensuring a stronger bond between particles.

Optimizing the SiC/Cu-Al2O3 Chemistry

Controlled Interfacial Reactions

For SiC/Cu-Al2O3 composites, the interface between the ceramic and metal is critical.

Precise temperature control in vacuum hot pressing provides the activation energy needed to induce a moderate reaction between SiC and the Cu matrix, forming Cu9Si, which strengthens interfacial bonding without degrading the material.

In-Situ Reinforcement Generation

The process supports complex in-situ chemical reactions necessary for this specific composite.

It promotes the internal oxidation reaction between Cu2O (in raw materials) and Aluminum (in the alloy powder) to generate a dispersed Al2O3 reinforcement phase, enhancing the composite's strength.

Protection via Vacuum Environment

Vacuum hot press furnaces continuously remove gases from interstitial spaces during sintering.

This prevents unintended oxidation of the copper matrix, ensures chemical stability, and aids in eliminating closed pores that would otherwise weaken the composite.

Understanding the Trade-offs

Processing Speed vs. Control

While hot pressing offers superior quality, it is generally a slower process compared to newer techniques like Spark Plasma Sintering (SPS).

SPS can heat at rates up to 1000°C/min, whereas Vacuum Hot Pressing (VHP) utilizes gentler heating rates.

The Benefit of Slower Heating

However, this slower speed is often an advantage for interface-sensitive systems like SiC/Al.

The longer holding windows and gentler heating of VHP facilitate uniform solid-state diffusion and prevent excessive, harmful reaction products that can occur with rapid heating.

Making the Right Choice for Your Goal

To maximize the performance of your SiC/Cu-Al2O3 composites, select your method based on your specific structural requirements:

- If your primary focus is Maximum Density: Choose hot press sintering to utilize plastic flow and diffusion creep for eliminating pores and achieving densities near theoretical limits.

- If your primary focus is Interfacial Bonding: Rely on vacuum hot pressing to strictly control chemical reactions, ensuring the formation of beneficial Cu9Si without excessive brittle phases.

- If your primary focus is Microstructural Refinement: Use hot pressing to densify the material at lower temperatures, preventing grain growth and ensuring a fine, uniform grain structure.

Ultimately, hot press sintering is the definitive choice when material integrity and precise microstructural control outweigh the need for rapid production speed.

Summary Table:

| Feature | Cold Press Sintering | Hot Press Sintering (VHP) |

|---|---|---|

| Process Integration | Separate forming & sintering | Simultaneous heat & pressure |

| Sintering Temp | High | Significantly Lower |

| Typical Density | Lower / Non-uniform | High (up to 97.6%) |

| Grain Structure | Prone to coarsening | Fine-grained (suppressed growth) |

| Interfacial Bond | Weak / Uncontrolled | Strong (controlled Cu9Si formation) |

| Atmosphere | Ambient or inert | Vacuum (prevents oxidation) |

Elevate Your Material Integrity with KINTEK

Unlock the full potential of your advanced composites with our precision-engineered thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum Hot Press, Muffle, Tube, Rotary, and CVD systems, all fully customizable to meet your unique research and production needs.

Whether you require precise interfacial control for SiC/Cu-Al2O3 composites or high-density grain refinement, our high-temperature furnaces provide the reliability your lab demands. Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the application of mechanical pressure contribute to the vacuum hot pressing formation of TiAl/Ti6Al4V? Expert Analysis

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What function does a vacuum hot press furnace serve in the densification of Nb-22.5Cr-5Si alloys? Achieve Full Density and Purity for Refractory Alloys

- How does the vacuum press contribute to material property improvement? Achieve Denser, Purer Materials for Superior Performance

- What Role Does a Graphite Mold Play in Vacuum Hot Pressing? Enhancing Composite Sintering Efficiency

- What are the benefits of the high vacuum environment in a vacuum hot pressing sintering furnace? Gain Maximum Density

- What are the main components of a vacuum hot press sintering furnace? Unlock Precision in Material Densification