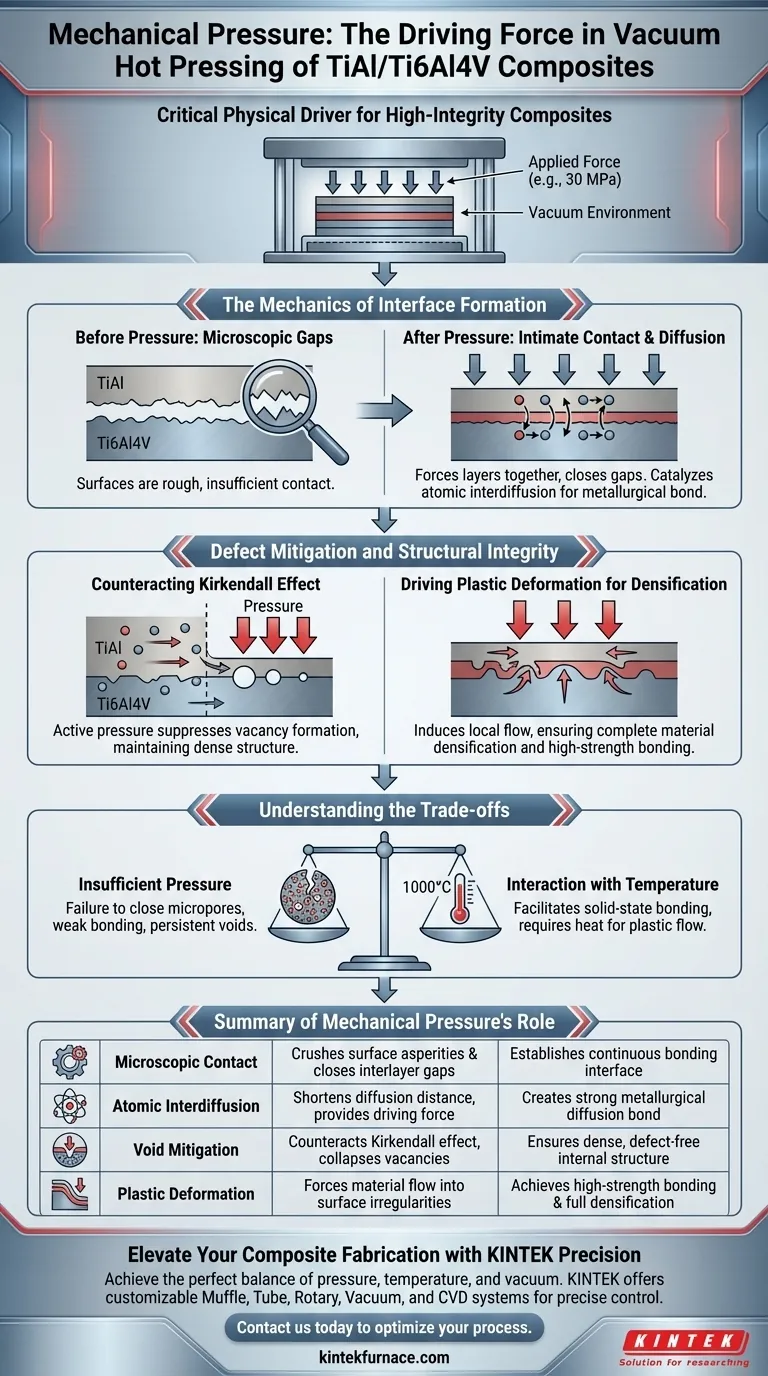

The application of mechanical pressure is the critical physical driver for creating high-integrity TiAl/Ti6Al4V layered composites. By applying a constant force, typically around 30 MPa, the process forces the distinct alloy layers into intimate contact, effectively closing microscopic gaps and driving the atomic interdiffusion necessary for a strong metallurgical bond.

The primary role of mechanical pressure in this context is to mechanically overcome the natural barriers to bonding. It actively forces material densification and counteracts the formation of voids, ensuring the final composite is a solid, continuous structure rather than a loosely adhered stack of foils.

The Mechanics of Interface Formation

Achieving Intimate Microscopic Contact

The surfaces of TiAl and Ti6Al4V layers are never perfectly smooth at a microscopic level. Simply stacking them does not create sufficient contact points for bonding.

Mechanical pressure forces these layers together, crushing surface asperities and closing the tiny interlayer gaps. This creates a continuous interface where atoms from adjacent layers can interact directly.

Promoting Atomic Interdiffusion

Once the physical gaps are closed, the pressure acts as a catalyst for atomic movement. It shortens the distance atoms must travel to cross the interface barrier.

By providing a necessary driving force, pressure accelerates the mutual diffusion of titanium and aluminum atoms. This results in the creation of a diffusion interface layer of appropriate width, which is the structural "glue" of the composite.

Defect Mitigation and Structural Integrity

Counteracting the Kirkendall Effect

A major challenge in diffusion bonding is the Kirkendall effect, where different diffusion rates between materials can create vacancies and voids.

The continuous application of pressure (e.g., 30 MPa) actively suppresses this phenomenon. It collapses these potential voids as they form, maintaining a dense, defect-free internal structure.

Driving Plastic Deformation for Densification

Pressure induces local plastic deformation at the interface. This forces the material to flow into any remaining irregularities or pores.

This mechanism ensures complete material densification. It transforms the layered stack into a unified component capable of achieving high-strength bonding similar to theoretical density.

Understanding the Trade-offs

While pressure is essential, it operates within a delicate balance alongside temperature and vacuum levels.

Insufficient Pressure results in a failure to close micropores. This leads to weak bonding and the persistence of voids, significantly compromising the mechanical properties of the composite.

Interaction with Temperature is also critical. Pressure facilitates bonding without melting the material (solid-state bonding), but it relies on the high temperatures (e.g., 1000°C) to soften the material enough for plastic flow to occur. Relying on pressure alone without adequate thermal energy will not achieve the necessary diffusion.

Optimizing Process Parameters for Quality

To achieve the best results in TiAl/Ti6Al4V composite fabrication, you must align pressure application with your specific outcome requirements.

- If your primary focus is defect elimination: Prioritize maintaining continuous pressure (e.g., 30 MPa) throughout the hold time to actively close voids caused by the Kirkendall effect.

- If your primary focus is bond strength: Ensure the pressure is sufficient to induce plastic deformation at the interface, maximizing the contact area for atomic interdiffusion.

Ultimately, mechanical pressure transforms a stack of separate alloys into a single, high-performance composite by physically enforcing the conditions required for atomic unity.

Summary Table:

| Mechanism | Role of Mechanical Pressure | Impact on Composite Quality |

|---|---|---|

| Microscopic Contact | Crushes surface asperities and closes interlayer gaps | Establishes a continuous interface for bonding |

| Atomic Interdiffusion | Shortens diffusion distance and provides driving force | Creates a strong metallurgical diffusion bond |

| Void Mitigation | Counteracts the Kirkendall effect and collapses vacancies | Ensures a dense, defect-free internal structure |

| Plastic Deformation | Forces material flow into surface irregularities | Achieves high-strength bonding and full densification |

Elevate Your Composite Fabrication with KINTEK Precision

Achieving the perfect balance of pressure, temperature, and vacuum is critical for high-performance TiAl/Ti6Al4V composites. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temp furnaces.

Our systems are fully customizable to meet your unique materials science needs, ensuring precise control over every parameter. Contact us today to discover how our advanced heating solutions can optimize your diffusion bonding and densification processes.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What factors should be considered when selecting vacuum press equipment? Key Insights for Optimal Performance

- What factors should be considered when choosing a vacuum press for metalworking? Optimize Your Investment for Precision and Efficiency

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- How does hot pressing minimize workpiece deformation? Achieve Precision with Lower Heat and Pressure

- What are the benefits of the high vacuum environment in a vacuum hot pressing sintering furnace? Gain Maximum Density

- Which industries commonly use hot press furnaces? Unlock Superior Material Performance

- How are hot press furnaces involved in semiconductor manufacturing? Essential for Wafer Bonding in 3D ICs