Selecting the right vacuum press is a decision that hinges on four critical factors. You must perform a methodical evaluation of your material requirements for temperature and pressure, the physical size and capacity needed for your parts, the level of control precision your process demands, and the long-term maintenance and durability of the equipment itself.

The most common mistake is focusing on the press itself rather than the process it serves. The ideal vacuum press is not the one with the most features, but the one whose core components—chamber, vacuum, heat, and control—are perfectly aligned with your material's specific lamination or forming requirements.

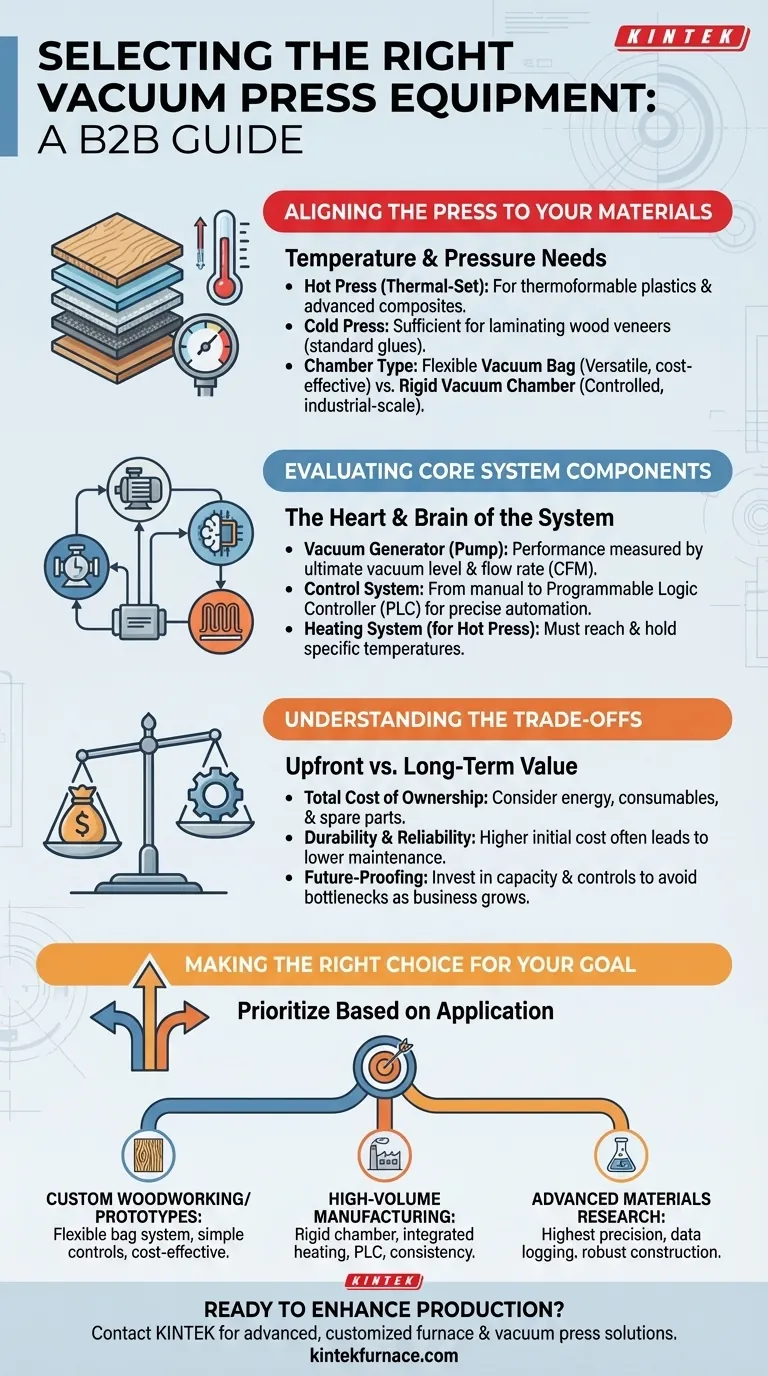

Aligning the Press to Your Materials

The primary function of a vacuum press is to use atmospheric pressure to laminate or form materials. Therefore, your material's properties must be the starting point for your selection process.

Defining Temperature Needs (Hot vs. Cold Press)

Most applications fall into two categories. Cold pressing is sufficient for tasks like laminating wood veneers with standard PVA glues.

If you are working with thermoformable plastics, advanced composites, or specific adhesives that require a thermal-set cycle, a hot press is non-negotiable. The heating system must be capable of reaching and holding the specific temperatures your materials require.

Determining Pressure and Chamber Needs

The press must create a sealed environment. For many woodworking or small-scale composite tasks, a flexible vacuum bag is highly versatile and cost-effective.

For industrial-scale production, metalworking, or processes requiring absolute repeatability, a rigid vacuum chamber is superior. It provides a more controlled environment and is better suited for automation.

Evaluating Core System Components

A vacuum press is a system of interconnected parts. The quality and suitability of each component directly impact the final result.

The Vacuum Generator: The Heart of the System

The vacuum generator, or pump, is what removes air to create pressure. Its performance is measured by the ultimate vacuum level it can achieve and its flow rate (CFM).

A pump that is undersized for the chamber will take too long to evacuate air, potentially compromising the process. A pump that is oversized is an unnecessary energy and capital expense.

The Control System: The Brain of the Operation

For simple cold pressing, basic manual controls may be adequate. However, for any process involving heat or complex materials, a precise control system is essential.

Look for systems that allow you to program and automate cycles. A Programmable Logic Controller (PLC) offers the highest degree of precision, ensuring that temperature, vacuum level, and time are managed perfectly for every run.

Understanding the Trade-offs

A vacuum press is a long-term investment. Looking beyond the initial sticker price is critical to making a sound financial and operational decision.

Upfront Cost vs. Total Cost of Ownership

The cheapest machine is rarely the least expensive to own. Consider factors like energy consumption, the cost of consumables (like vacuum bags or seals), and the availability and price of spare parts.

A more durable, well-built machine from a reputable manufacturer may have a higher initial cost but will prove more reliable and less expensive to maintain over its lifetime.

Future-Proofing Your Investment

Consider not only your current needs but also your future plans. Buying a press with slightly more capacity or more advanced controls than you need today can prevent the need for a costly replacement as your business grows.

An undersized press will quickly become a production bottleneck, limiting your ability to take on larger or more complex projects.

Making the Right Choice for Your Goal

Your specific application dictates which features to prioritize. Use your primary goal to guide your final decision.

- If your primary focus is custom woodworking or one-off prototypes: A flexible vacuum bag system with a simple, reliable pump and manual controls offers the best versatility and cost-effectiveness.

- If your primary focus is high-volume composite or plastics manufacturing: Prioritize a rigid chamber press with an integrated heating system and a PLC for process consistency and repeatability.

- If your primary focus is metal forming or advanced materials research: Invest in a system with the highest degree of control precision, data logging, and robust construction to handle extreme temperatures and pressures.

Ultimately, a thorough analysis of your process will lead you to the press that is not just a purchase, but a long-term production asset.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material Requirements | Temperature (hot/cold press), pressure needs, and material type (e.g., composites, wood) |

| System Components | Vacuum generator (pump), control system (e.g., PLC), and chamber type (bag vs. rigid) |

| Cost and Investment | Upfront cost, total cost of ownership, and future-proofing for growth |

| Application Goals | Custom woodworking, high-volume manufacturing, or advanced materials research |

Ready to enhance your production with the perfect vacuum press? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs. Contact us today to discuss how our tailored solutions can boost your efficiency and reliability!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What are the typical operational steps when using a vacuum press? Master Flawless Bonding and Forming

- What is a vacuum press and why is it important in modern manufacturing? Unlock Flawless Bonding and Precision

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- What are the key applications of vacuum pressing in composite material processing? Enhance Material Quality and Shape Complexity