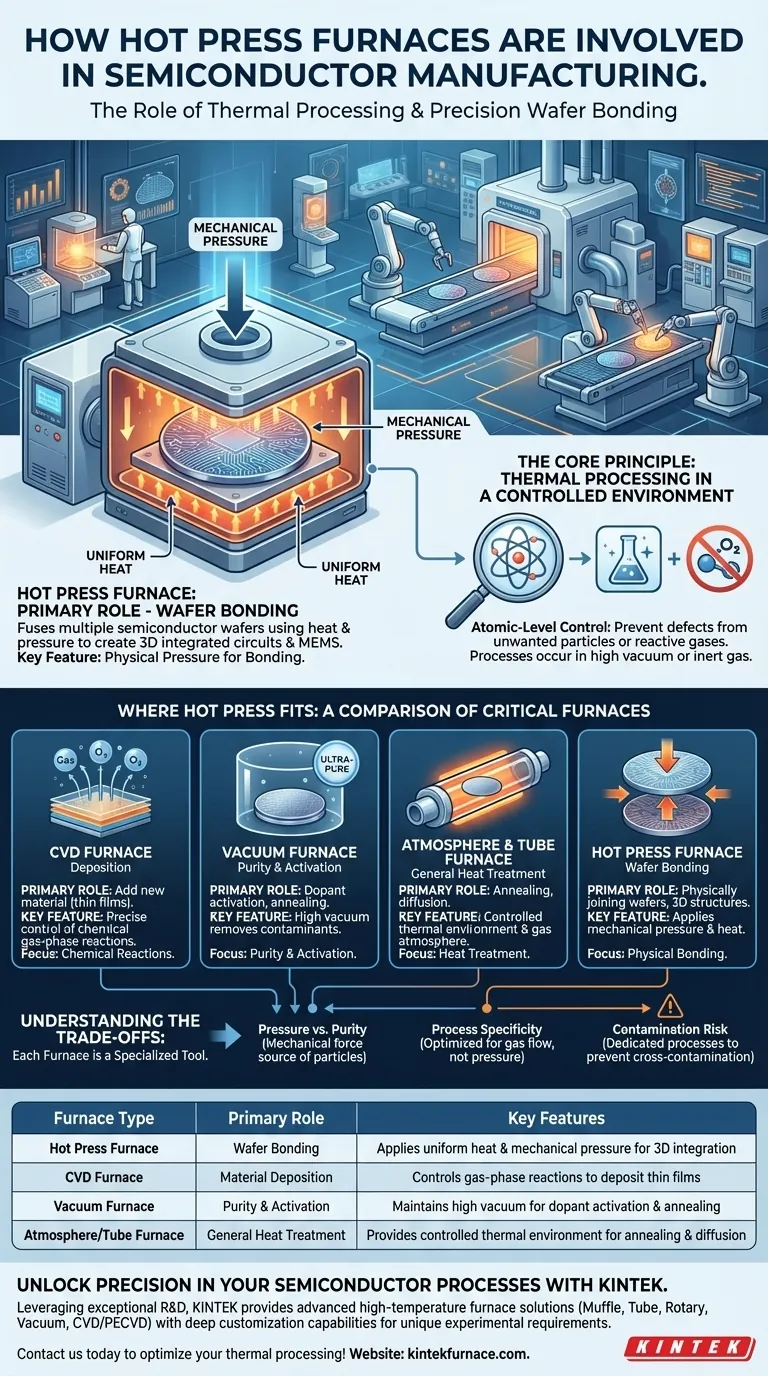

In semiconductor manufacturing, the primary role of a hot press furnace is for wafer bonding. This specialized process uses a combination of precisely controlled heat and mechanical pressure to fuse two or more semiconductor wafers together, creating a single, multi-layered device. This technique is fundamental to producing advanced 3D integrated circuits and complex microelectromechanical systems (MEMS).

The core principle to understand is that different furnaces are purpose-built tools for different atomic-level tasks. While a hot press furnace uniquely applies physical pressure for bonding, other furnaces are designed for depositing films (CVD), purifying materials (vacuum), or modifying crystal structures (atmosphere).

The Core Principle: Thermal Processing in a Controlled Environment

In semiconductor fabrication, a "furnace" is far more than a simple oven. It is a highly sophisticated instrument for applying thermal energy within a meticulously controlled environment.

Why Control is Everything

The goal is to manipulate the properties of silicon wafers at an atomic level. Any unwanted particles or reactive gases, like oxygen, can introduce defects that destroy the final chip.

Therefore, these processes occur in a high vacuum or are filled with specific, inert gases. This ensures that the only changes happening to the wafer are the ones intended by the process engineers.

The Specific Role of the Hot Press Furnace

While many furnace processes exist, the hot press is defined by its use of mechanical force in addition to heat.

What is Wafer Bonding?

Think of wafer bonding as creating a multi-story building on a microscopic scale. Instead of fabricating all components on a single flat surface, engineers can build and optimize separate wafers and then stack and bond them together.

This "3D integration" allows for more complex, powerful, and smaller electronic devices.

How a Hot Press Enables Bonding

A hot press furnace applies uniform heat and significant mechanical pressure across the entire surface of the wafers. This combination causes the atoms on the surfaces of the wafers to bond, fusing them into a single, monolithic block of silicon without melting or creating defects. The pressure is the key ingredient that distinguishes this from other furnace types.

Where Hot Press Fits: A Comparison with Other Furnaces

To understand the role of a hot press, it is essential to compare it to other critical furnaces used in a fabrication plant.

For Deposition: Chemical Vapor Deposition (CVD) Furnaces

CVD furnaces are designed to add new material. They introduce carefully chosen gases that react and deposit extremely thin films—such as conductive or insulating layers—onto the wafer's surface. The focus here is on controlling chemical reactions, not applying physical pressure.

For Purity and Activation: Vacuum Furnaces

Vacuum furnaces excel at creating an ultra-pure environment. By removing virtually all air and contaminants, they are perfect for sensitive tasks like activating dopants (impurities intentionally added to silicon) or annealing thin films without the risk of oxidation. Their primary feature is the quality of the vacuum.

For General Heat Treatment: Atmosphere & Tube Furnaces

These furnaces are the workhorses for general thermal processing. They are used for annealing, a process that heats and cools a wafer to relieve internal stress in the silicon crystal lattice, and diffusion, which encourages dopants to spread evenly throughout a region of the wafer. Their function is defined by maintaining a specific temperature and gas atmosphere over time.

Understanding the Trade-offs

Each furnace is a highly specialized piece of equipment, and using the wrong one would lead to catastrophic failure.

Pressure vs. Purity

A hot press is optimized to deliver mechanical force evenly, but the components required to apply this pressure can be a potential source of particles if not engineered perfectly. In contrast, a CVD furnace is optimized for pristine gas flow dynamics and preventing any particle generation.

Process Specificity

The design of a furnace for depositing new layers (CVD) is fundamentally different from one built simply to heat a wafer (annealing) or press two wafers together (bonding). Each task demands a unique hardware configuration to control temperature, gas chemistry, and pressure with the required precision.

Contamination Risk

Cross-contamination is one of the biggest risks in semiconductor manufacturing. For this reason, furnaces are dedicated to specific processes. You would never use a furnace that handles metal deposition for a later, high-purity annealing step, as microscopic metal flakes could contaminate and ruin the wafers.

Making the Right Choice for Your Goal

The selection of a thermal process is dictated entirely by the desired physical or chemical transformation.

- If your primary focus is physically joining wafers to create 3D structures: A hot press furnace is the only tool that can apply the necessary uniform heat and mechanical pressure.

- If your primary focus is depositing new, thin layers of material onto a wafer: A Chemical Vapor Deposition (CVD) furnace is required for its precise control over gas-phase chemical reactions.

- If your primary focus is activating dopants or treating a surface in an ultra-pure, oxygen-free environment: A high-vacuum furnace is essential to prevent contamination and unwanted side reactions.

- If your primary focus is modifying the crystal properties of a wafer through general annealing or diffusion: An atmosphere or tube furnace provides the necessary controlled thermal environment for these bulk material changes.

Ultimately, understanding that each furnace is a purpose-built tool for a specific atomic-level task is the key to demystifying the complex world of semiconductor fabrication.

Summary Table:

| Furnace Type | Primary Role | Key Features |

|---|---|---|

| Hot Press Furnace | Wafer Bonding | Applies uniform heat and mechanical pressure for 3D integration |

| CVD Furnace | Material Deposition | Controls gas-phase reactions to deposit thin films |

| Vacuum Furnace | Purity and Activation | Maintains high vacuum for dopant activation and annealing |

| Atmosphere/Tube Furnace | General Heat Treatment | Provides controlled thermal environment for annealing and diffusion |

Unlock Precision in Your Semiconductor Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on wafer bonding, deposition, or purity control, our tailored furnaces deliver reliable performance and enhanced efficiency for your semiconductor fabrication needs.

Contact us today to discuss how KINTEK can optimize your thermal processing and drive innovation in your lab!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%