At its core, hot press furnaces are used by industries that require materials with exceptional density, strength, and performance characteristics that cannot be achieved through simple heating alone. The primary users are found in the aerospace, advanced ceramics, defense, automotive, and medical sectors, where components must withstand extreme conditions without failure.

The critical takeaway is that hot pressing is not just a heating process; it's a consolidation technology. By applying immense pressure at high temperatures, it forces powdered materials together, eliminating internal voids to create dense, monolithic parts with superior mechanical properties.

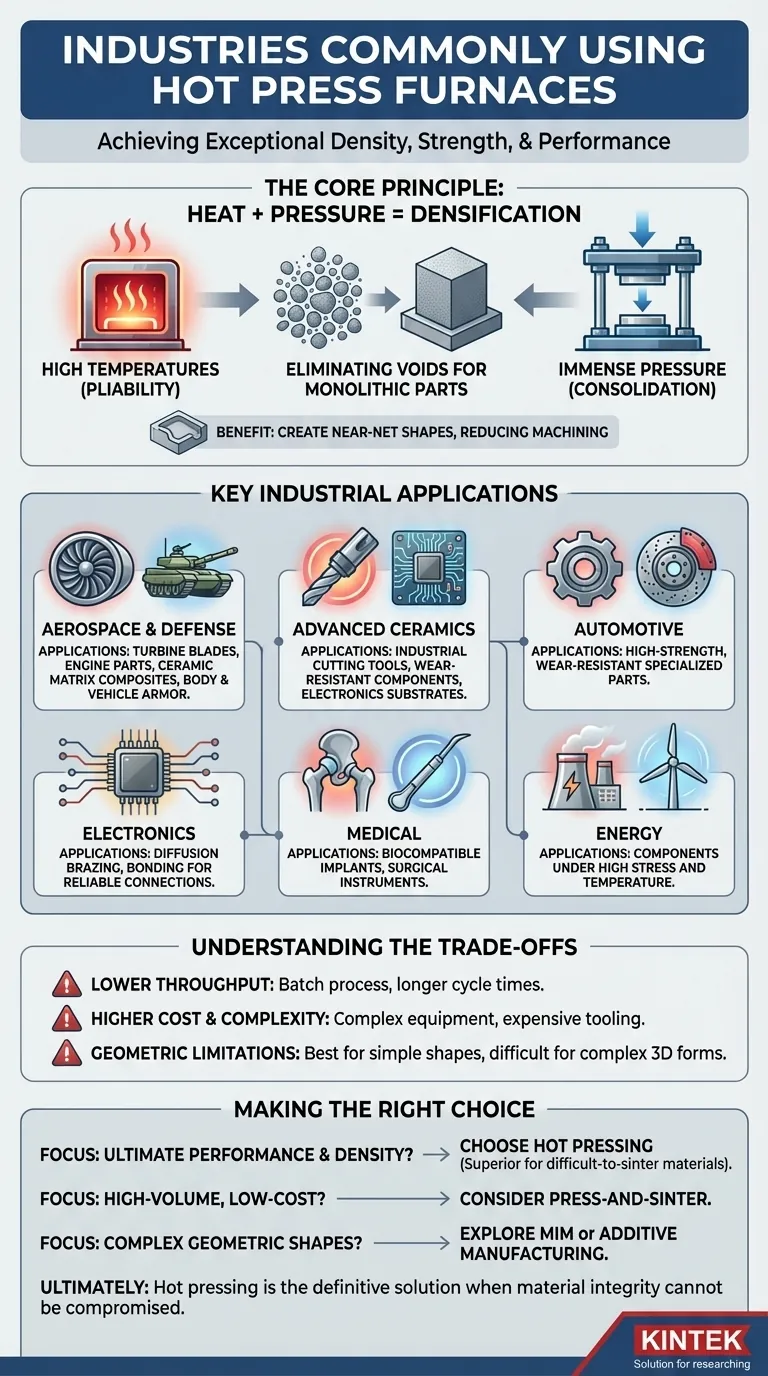

The Core Principle: Combining Heat and Pressure

A hot press furnace integrates a high-temperature furnace with a powerful hydraulic press. This unique combination allows for the simultaneous application of heat and mechanical force to a material, fundamentally changing its structure.

Densification Through Force

The primary goal of hot pressing is densification. Heat makes the material particles pliable, while the immense pressure physically forces them together, squeezing out the empty spaces (porosity) between them.

This process is especially critical for materials like ceramics or composite powders that do not bond well with simple heating (sintering) alone.

Creating Near-Net Shapes

A significant benefit of this process is its ability to produce near-net shapes. The material is pressed into a die that is very close to the final part's dimensions, drastically reducing the need for expensive and time-consuming post-process machining.

Key Industrial Applications

The need for highly dense, defect-free materials drives the adoption of hot pressing across several high-stakes industries.

Aerospace and Defense

In aerospace, components like turbine blades and engine parts must be lightweight yet incredibly strong and resistant to extreme temperatures. Hot pressing is used to create parts from advanced metal alloys and ceramic matrix composites (CMCs) that meet these demands.

For defense applications, the technology is essential for manufacturing body and vehicle armor. Hot pressing materials like boron carbide creates ultra-hard, monolithic ceramic plates that are lighter and more effective than traditional steel armor.

Advanced and Technical Ceramics

Hot pressing is the go-to method for producing high-strength, defect-free technical ceramics. These are not your typical pottery ceramics; they are engineered for extreme performance.

Applications include industrial cutting tools, wear-resistant components, and substrates for advanced electronics where thermal management and electrical insulation are critical.

Automotive and Electronics

In the high-performance automotive sector, hot pressing is used for specialized parts that require high strength and wear resistance.

In electronics, the process can be used for diffusion brazing or bonding. This creates permanent, high-reliability electromechanical connections between dissimilar materials that must endure thermal cycling and physical stress.

Medical and Energy

The medical field relies on hot pressing for manufacturing certain implants and surgical instruments. The process creates biocompatible, fully dense materials (like specific ceramics or metal alloys) that are strong and highly resistant to wear inside the human body.

In the energy sector, components for power generation equipment that operate under high stress and temperature are often produced using this method to ensure longevity and reliability.

Understanding the Trade-offs

While powerful, hot pressing is a specialized process with specific limitations that make it unsuitable for all applications.

Lower Throughput

Hot pressing is inherently a batch process. Each part or small group of parts must be loaded, pressed, cooled, and unloaded individually. This results in much longer cycle times compared to continuous processes like conventional sintering.

Higher Cost and Complexity

The equipment itself is complex and expensive, combining a high-force press with a controlled-atmosphere furnace. The tooling and dies must also be made from materials that can withstand the intense heat and pressure, adding to the operational cost.

Geometric Limitations

The process works best for parts with relatively simple geometries, such as discs, blocks, or plates. Applying uniform pressure to highly complex, three-dimensional shapes can be extremely difficult, leading to density variations and potential defects.

Making the Right Choice for Your Goal

Selecting a manufacturing process requires matching the technology's strengths to your product's most critical requirement.

- If your primary focus is ultimate material performance and density: Hot pressing is the superior choice for creating parts with minimal porosity and maximum strength, especially with difficult-to-sinter materials.

- If your primary focus is high-volume, low-cost production: A more conventional method like press-and-sinter would likely be a more cost-effective solution for less demanding applications.

- If your primary focus is creating highly complex geometric shapes: You should investigate alternatives like metal injection molding (MIM) or additive manufacturing (3D printing), which offer greater design freedom.

Ultimately, hot pressing is the definitive solution for applications where material integrity and performance cannot be compromised.

Summary Table:

| Industry | Key Applications |

|---|---|

| Aerospace | Turbine blades, engine parts, ceramic matrix composites |

| Defense | Body and vehicle armor, ultra-hard ceramic plates |

| Advanced Ceramics | Cutting tools, wear-resistant components, electronics substrates |

| Automotive | High-strength, wear-resistant parts |

| Electronics | Diffusion brazing, bonding for reliable connections |

| Medical | Implants, surgical instruments, biocompatible materials |

| Energy | Power generation components under high stress and temperature |

Ready to enhance your material performance with custom hot press furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in aerospace, defense, ceramics, or other high-stakes industries, we can help you achieve superior density and strength. Contact us today to discuss how we can support your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure