The primary benefit of a high vacuum environment in hot pressing is the creation of a pristine, chemically inert processing zone that simultaneously evacuates trapped gases and prevents material degradation. By maintaining a vacuum level such as 5×10⁻² Pa, the system eliminates atmospheric interference, ensuring that the physical consolidation of powder leads to maximum density rather than porous, brittle structures.

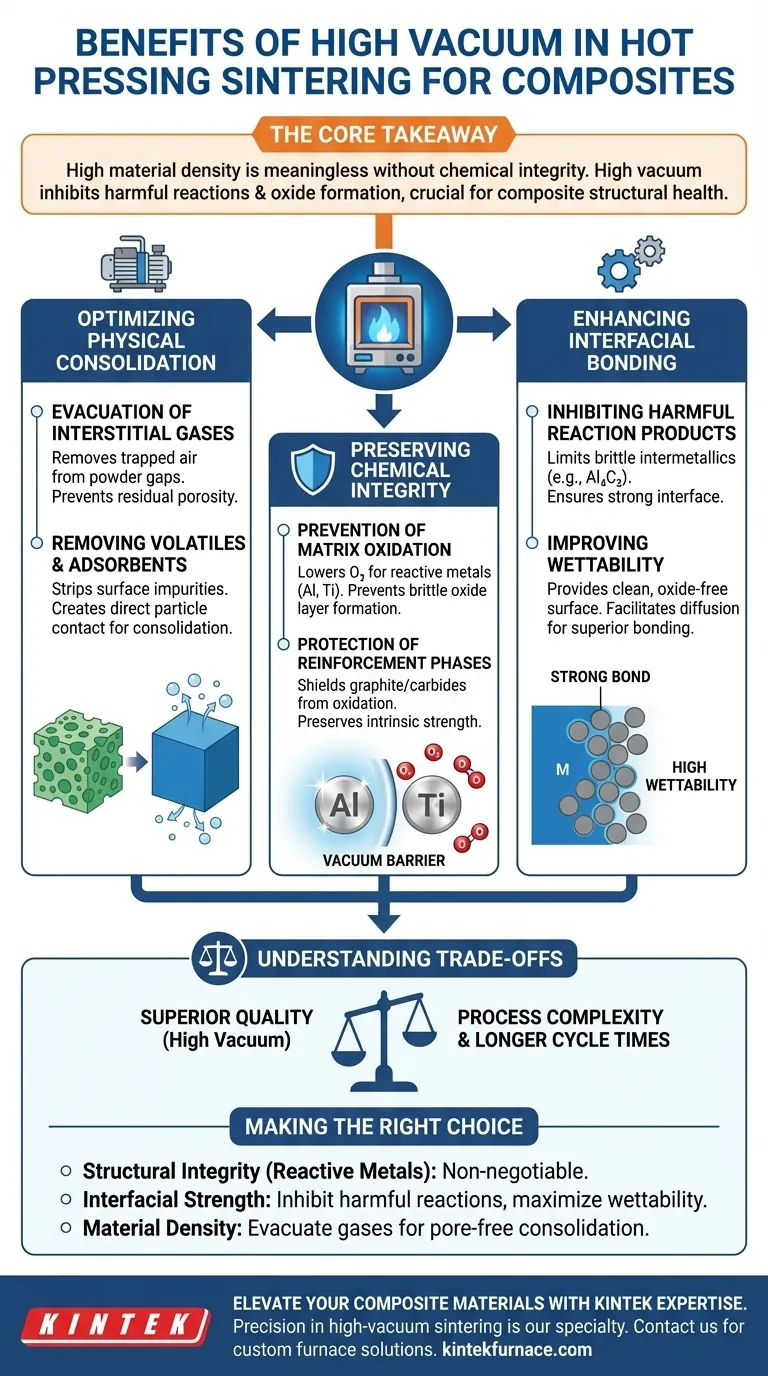

The Core Takeaway Achieving high material density is meaningless if the chemical integrity of the interface is compromised. The high vacuum environment is not just about removing air; it is a critical control mechanism that inhibits harmful chemical reactions and oxide formation, which are the primary causes of structural failure in composite materials.

Optimizing Physical Consolidation

Evacuation of Interstitial Gases

In powder metallurgy, air is naturally trapped in the gaps (interstices) between particles. A high vacuum environment effectively evacuates these gases before the sintering process seals the material.

If these gases are not removed, they become trapped as pores within the final composite. This leads to residual porosity, which significantly reduces the material's final density and mechanical strength.

Removing Volatiles and Adsorbents

Beyond interstitial air, powder surfaces often hold adsorbed gases and volatile contaminants. The vacuum system strips these impurities away as the temperature rises.

This "cleaning" of the powder surface creates a direct path for particle-to-particle contact. It removes physical barriers that would otherwise hinder the consolidation process.

Preserving Chemical Integrity

Prevention of Matrix Oxidation

Many composite matrices, particularly aluminum alloys and titanium, are highly reactive to oxygen at sintering temperatures (e.g., 950°C to 1250°C). The vacuum environment lowers the oxygen partial pressure to negligible levels.

This prevents the formation of oxide layers on the particle surfaces. Oxide layers act as brittle contaminants that prevent true metallurgical bonding and serve as crack initiation sites in the final product.

Protection of Reinforcement Phases

It is not only the metal matrix that is vulnerable; reinforcement materials like graphite or carbides can also degrade in the presence of oxygen. The vacuum atmosphere shields these reinforcements from oxidation and decarburization.

Preserving the reinforcement phase ensures that it retains its intrinsic strength. This allows it to effectively carry the load within the composite structure as intended.

Enhancing Interfacial Bonding

Inhibiting Harmful Reaction Products

A critical function of the vacuum environment is limiting the formation of brittle intermetallic compounds. For example, in aluminum-graphite composites, excessive reaction can form aluminum carbide, a harmful product that degrades material properties.

By controlling the atmosphere, the vacuum process inhibits these excessive interfacial reactions. This control is decisive for ensuring the bonding interface remains strong rather than brittle.

Improving Wettability

For a composite to be strong, the liquid or semi-solid matrix must "wet" the reinforcement particles thoroughly. Oxygen and surface oxides notoriously inhibit this wetting behavior.

By providing a clean, oxide-free surface, the vacuum environment improves wettability between the matrix and the reinforcement. This facilitates atomic diffusion and migration, leading to a superior metallurgical bond.

Understanding the Trade-offs

Process Complexity and Cost

While high vacuum offers superior quality, it introduces significant complexity. Achieving and maintaining vacuum levels like 5×10⁻² Pa or 10⁻³ Pa requires sophisticated pumping systems and meticulous seal maintenance.

Cycle Time Implications

Vacuum hot pressing is inherently a batch process that requires time for pump-down and outgassing. This can result in longer cycle times compared to atmospheric or inert gas sintering methods, making it a choice driven by quality requirements rather than throughput speed.

Making the Right Choice for Your Goal

The decision to utilize high vacuum hot pressing depends on the specific chemical sensitivities of your materials.

- If your primary focus is Structural Integrity: The vacuum is non-negotiable for reactive metals (Ti, Al) to eliminate brittle oxide inclusions that cause premature failure.

- If your primary focus is Interfacial Strength: Rely on the vacuum to inhibit harmful reaction products (like aluminum carbide) and maximize the wettability between the matrix and reinforcement.

- If your primary focus is Material Density: Use the vacuum to evacuate interstitial gases, ensuring pore-free consolidation for applications requiring high hermeticity.

Ultimately, the high vacuum environment transforms the sintering process from a simple heating operation into a precise chemical control system, vital for high-performance composites.

Summary Table:

| Benefit Category | Primary Mechanism | Impact on Material Quality |

|---|---|---|

| Physical Consolidation | Evacuation of interstitial gases & volatiles | Eliminates porosity; achieves maximum theoretical density |

| Chemical Integrity | Low oxygen partial pressure | Prevents matrix oxidation (Al, Ti) and reinforcement degradation |

| Interfacial Bonding | Removal of surface oxides | Improves wettability and inhibits brittle intermetallic compounds |

| Structural Strength | Surface "cleaning" of powders | Ensures direct metallurgical bonding and reduces crack initiation |

Elevate Your Composite Materials with KINTEK Expertise

Precision in high-vacuum sintering is the difference between a porous failure and a high-performance breakthrough. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, all meticulously engineered to meet the rigorous demands of modern material science.

Why choose KINTEK?

- Advanced R&D: Our furnaces are backed by expert research to ensure optimal thermal uniformity and vacuum stability.

- Tailored Solutions: Whether you are working with reactive titanium or complex graphite composites, our systems are fully customizable to your unique process parameters.

- Superior Reliability: We specialize in high-temp lab furnaces designed for maximum durability and chemical control.

Ready to eliminate oxidation and achieve maximum material density? Contact us today to discuss your custom furnace needs.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What role does a sealed quartz glass tube play in hot press sintering? Achieve Oxide-Free Aluminum Composites

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What environment does a vacuum hot pressing furnace provide for coatings? Achieve Superior Bond Strength & Density

- What is the purpose of vacuum hot pressing? Achieve Superior Material Density and Purity

- How does the vacuum environment in a vacuum hot press sintering furnace protect chromium-containing ceramics? Find out.

- How does the vacuum environment affect AlMgTi composite hot pressing? Unlock Superior Bonding & Density

- What is the function of high-purity graphite molds in FAST? The Key to Precision Sintering Performance

- What are the key advantages of vacuum hot press furnaces compared to conventional furnaces? Achieve Superior Purity and Control