At their core, vacuum hot press furnaces offer transformative advantages over conventional furnaces by creating an ultra-pure, controlled environment. This allows for superior material properties, unmatched process repeatability, and a safer operational profile, which are simply unattainable in a standard atmosphere. The primary benefits revolve around preventing contamination and enabling precise control over both temperature and pressure.

The decision to use a vacuum hot press is not about choosing a faster furnace, but about choosing a fundamentally different processing tool. It prioritizes the creation of materials with the highest possible purity, density, and specific metallurgical properties, where conventional methods would fail.

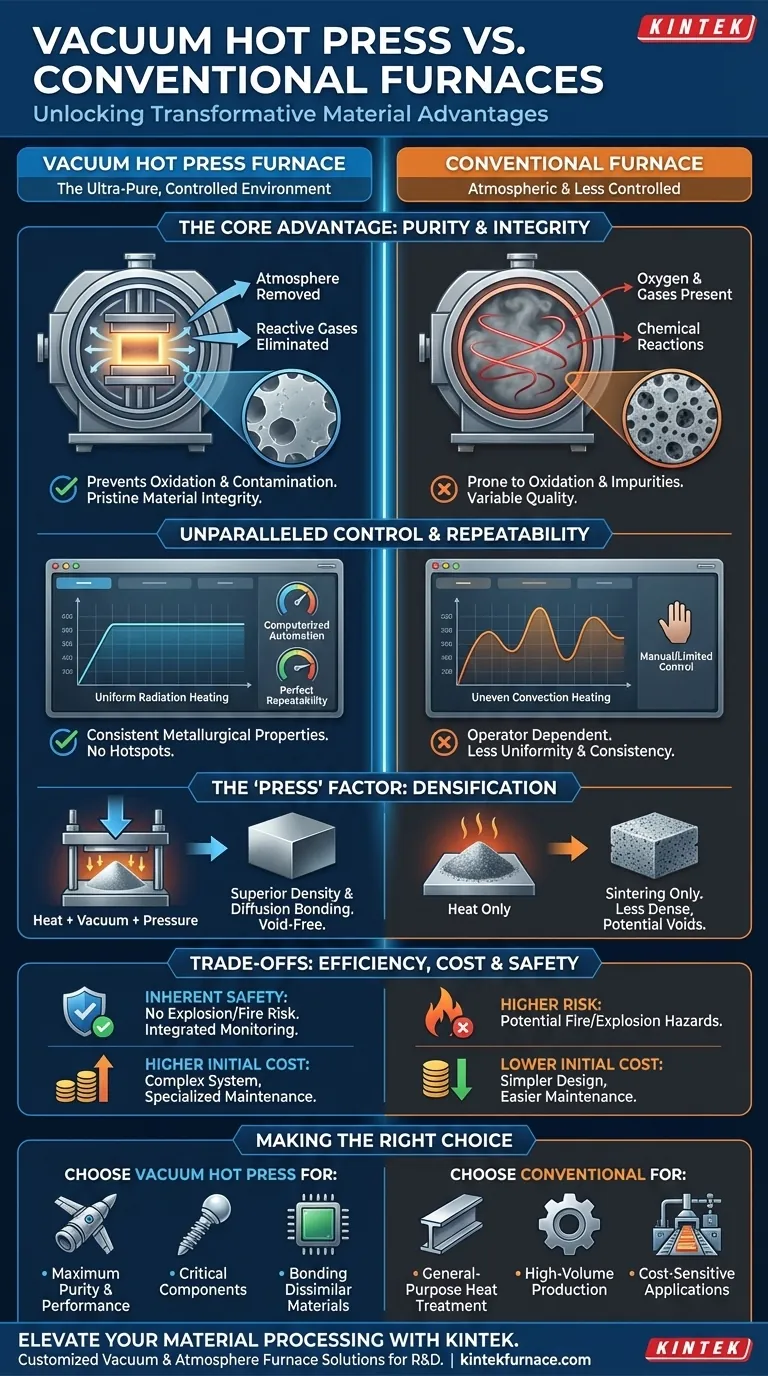

The Core Advantage: An Ultra-Pure Processing Environment

The defining feature of a vacuum furnace is its ability to remove the atmosphere—and the impurities within it—from the equation. This has profound effects on the final product.

Preventing Oxidation and Contamination

In a conventional furnace, the material is heated in the presence of oxygen and other atmospheric gases. This inevitably leads to oxidation and other chemical reactions on the material's surface, introducing impurities.

A vacuum furnace operates by pumping out the air to create a negative-pressure environment. By removing reactive gases, it effectively prevents contamination, ensuring the material's chemical composition remains pristine.

Achieving Uncompromised Material Integrity

This impurity-free environment is critical for processing high-performance and reactive materials like superalloys, advanced ceramics, and titanium.

The result is a final product with superior material properties and a clean surface finish. This is essential for applications in aerospace, medical, and advanced electronics where even minor impurities can lead to component failure.

Unparalleled Control Over Process Variables

Beyond purity, vacuum hot presses provide a level of process control that conventional furnaces cannot match. This precision is the key to consistency and advanced material engineering.

Precision Temperature Uniformity

Vacuum furnaces heat primarily through radiation, which provides highly uniform heating across the entire workpiece. This eliminates the hotspots and cold spots common in conventional convection furnaces.

This uniformity ensures that the entire part undergoes the exact same thermal cycle, resulting in consistent metallurgical properties, reduced internal stresses, and less warpage.

Computerized Control for Perfect Repeatability

Modern vacuum hot presses are highly automated systems. Temperature, pressure, and vacuum levels are managed by a computer according to a pre-programmed recipe.

This automation ensures that every process is identical, leading to exceptional repeatability from one batch to the next. It removes operator guesswork and guarantees consistent quality control.

The "Press" in Hot Press: Densification Under Vacuum

The "hot press" function adds another layer of control. While the material is held at a precise temperature in a vacuum, a mechanical press applies force.

This simultaneous application of heat, vacuum, and pressure is used for densification, diffusion bonding, and sintering of powders into a solid, void-free mass, which is impossible in a standard furnace.

Understanding the Trade-offs: Efficiency and Cost

While the advantages are significant, vacuum hot presses are not a universal solution. Understanding their operational profile is key to making an informed decision.

The Myth of "Faster vs. Slower"

The efficiency of a vacuum furnace is nuanced. The process of pumping down to a vacuum and, in some cases, backfilling with inert gas can make the total cycle time longer than in a simple conventional furnace.

However, the heating phase can be more energy-efficient, as energy is not wasted heating large volumes of air. Furthermore, modern designs with advanced water-cooled shells allow for rapid and controlled cooling, which can be a critical part of the heat treatment process itself.

Higher Initial Investment

Vacuum hot press furnaces are complex machines incorporating vacuum pumps, precise controls, and robust chamber designs. This results in a significantly higher initial capital cost compared to most conventional furnaces.

Maintenance and Operational Complexity

The complexity of the system, particularly the vacuum pumps and seals, requires more specialized knowledge for operation and maintenance. This can translate to higher long-term operational costs and the need for more highly trained staff.

Inherent Safety by Design

Vacuum technology fundamentally alters the safety profile of high-temperature processing, eliminating common industrial risks.

Eliminating Explosion and Fire Risks

Because they operate at a negative pressure, vacuum furnaces have virtually no risk of explosion from over-pressurization.

The low-oxygen environment also eliminates the conditions necessary for combustion, mitigating the risk of fire that can exist in standard furnaces, especially when processing materials with oil or other coatings.

Integrated Safety Monitoring

These furnaces are typically equipped with a suite of automated safety interlocks. Alarms for over-temperature, loss of cooling water, or over-current conditions provide an integrated layer of protection for both the equipment and personnel.

Making the Right Choice for Your Application

Choosing between a vacuum hot press and a conventional furnace depends entirely on your material requirements, quality standards, and budget.

- If your primary focus is maximum material purity and performance (e.g., aerospace alloys, medical implants, advanced ceramics): The contamination control and property enhancement of a vacuum hot press are non-negotiable.

- If your primary focus is high-volume, general-purpose heat treatment (e.g., basic steel annealing or tempering): The cost and throughput advantages of a conventional furnace make it the more practical choice.

- If your primary focus is bonding dissimilar materials or creating fully dense powder metal parts: The unique combination of heat, vacuum, and pressure in a vacuum hot press is essential.

- If your primary focus is process repeatability for critical components: The precise, automated control of a vacuum furnace delivers consistency that is difficult to achieve manually.

Ultimately, investing in a vacuum hot press is a decision to prioritize absolute control over the material's final form and function.

Summary Table:

| Advantage | Vacuum Hot Press Furnace | Conventional Furnace |

|---|---|---|

| Purity | Prevents oxidation and contamination | Prone to oxidation and impurities |

| Control | Uniform heating, precise temperature/pressure | Less uniform, limited control |

| Material Properties | Superior density and integrity | Variable quality |

| Repeatability | High with automation | Lower, operator-dependent |

| Safety | Low explosion/fire risk | Higher risk in certain conditions |

| Cost | Higher initial investment | Lower initial cost |

Ready to elevate your material processing with precision and purity? At KINTEK, we specialize in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored to meet the unique needs of industries like aerospace, medical, and electronics. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to ensure your experiments achieve uncompromised results. Contact us today to discuss how our vacuum hot press furnaces can transform your lab's capabilities and drive innovation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals