In short, hot pressing delivers components with superior mechanical properties, high dimensional accuracy, and exceptional material integrity. By simultaneously applying high temperature and pressure, often within a vacuum, this process consolidates materials into a dense, solid form with minimal porosity, making it a preferred method for creating high-performance parts.

Hot pressing is more than a shaping technique; it is a material consolidation process. Its primary value lies in its ability to achieve near-total densification, fundamentally enhancing a material's intrinsic properties by eliminating voids and ensuring complete molecular bonding.

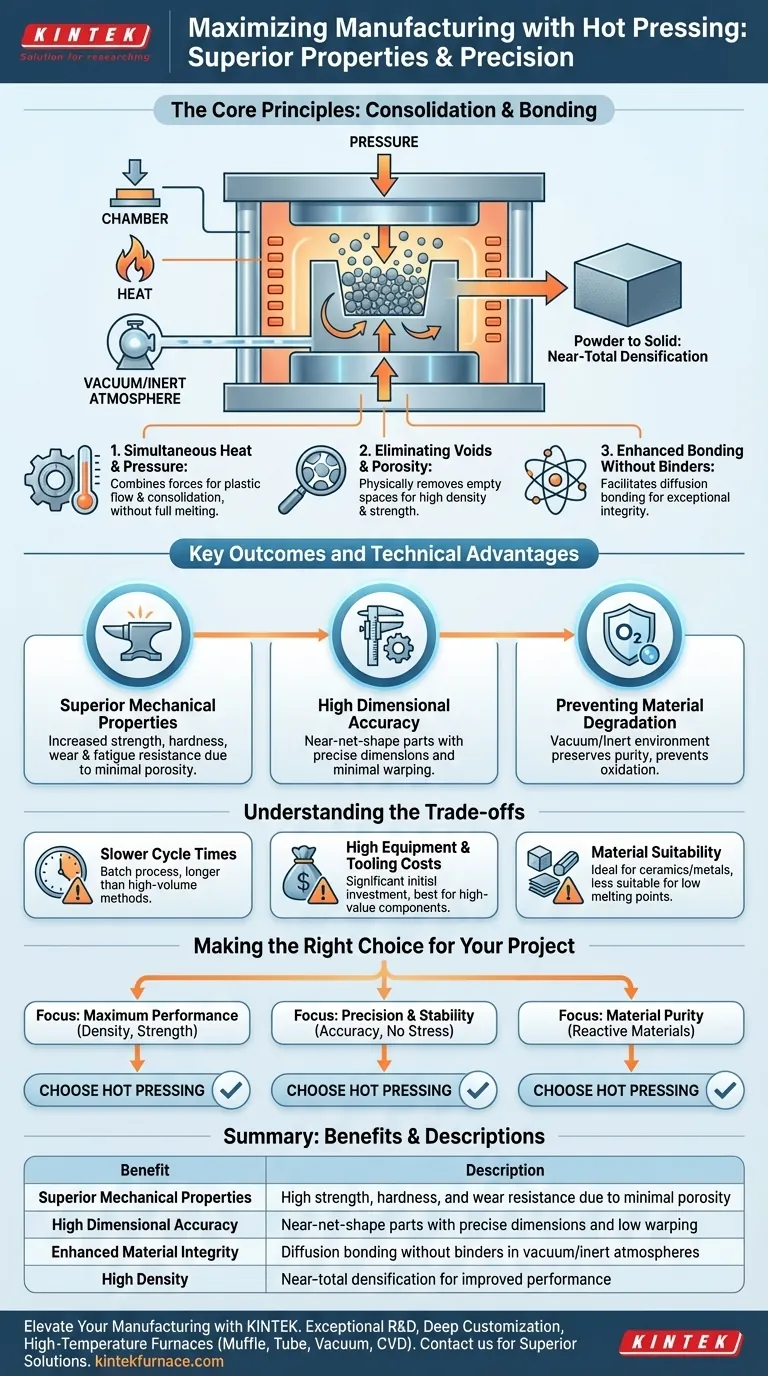

The Core Principles of Hot Pressing

To understand its benefits, you must first understand how hot pressing fundamentally alters a material. It is not simply about melting and forming; it is about forcing solid particles to bond under extreme conditions.

Simultaneous Heat and Pressure

The process combines controlled heating with immense pressure. This allows the material's particles to deform and flow plastically, filling in any gaps between them without necessarily reaching the full melting point.

This combination is what enables the consolidation of powders into a solid, monolithic structure.

Eliminating Voids and Porosity

The applied pressure physically forces out the empty spaces (porosity) between material grains or particles. The result is a final product with extremely high density, often approaching 100% of the material's theoretical maximum.

High density is directly correlated with superior strength and performance.

Enhanced Bonding Without Binders

Many powder-based manufacturing methods require chemical binders to hold particles together, which can become points of failure. Hot pressing eliminates the need for these binders.

The heat and pressure facilitate diffusion bonding, where atoms from adjacent particles migrate across boundaries to form a single, continuous solid part with exceptional integrity.

Key Outcomes and Technical Advantages

The principles of hot pressing translate directly into tangible benefits that are critical for demanding applications in aerospace, defense, and medical industries.

Superior Mechanical Properties

By creating a nearly void-free structure, hot pressing produces parts that are significantly stronger, harder, and more resistant to wear and fatigue. The absence of internal defects means there are fewer points where cracks can initiate.

High Dimensional Accuracy

The material flows uniformly within a rigid mold under precise control. This minimizes warping and internal stress, resulting in a near-net-shape part that requires little to no post-processing. The final component conforms precisely to the mold's dimensions.

Preventing Material Degradation

Many advanced materials, including certain metals and ceramics, are highly reactive with oxygen at high temperatures. Hot pressing is often performed in a vacuum or inert gas environment.

This atmosphere prevents oxidation and contamination, preserving the material's chemical purity and ensuring its intended performance characteristics are not compromised.

Understanding the Trade-offs

No manufacturing process is without its limitations. Objectivity requires acknowledging where hot pressing might not be the ideal choice.

Slower Cycle Times

Hot pressing is a batch process that requires precise control over heating, soaking, and cooling cycles. Compared to high-volume methods like injection molding or die casting, its cycle times are significantly longer.

High Equipment and Tooling Costs

Vacuum hot presses and the specialized molds—often made from graphite or ceramic composites—are expensive. This high initial investment makes the process best suited for high-value components where performance justifies the cost.

Material Suitability

The process is ideal for ceramics, metal powders, and composites that benefit from densification. However, it is less suitable for materials with low melting points or those that might degrade under the required heat and pressure.

Making the Right Choice for Your Project

Selecting hot pressing depends entirely on your project's non-negotiable requirements. Use these guidelines to determine if it aligns with your goals.

- If your primary focus is maximum performance: Choose hot pressing when you require the highest possible material density, strength, and hardness for a critical application.

- If your primary focus is precision and stability: Use this method for complex parts where dimensional accuracy and the absence of internal stress are paramount.

- If your primary focus is material purity: Hot pressing in a vacuum is essential when working with reactive materials that cannot tolerate oxidation during fabrication.

Ultimately, hot pressing is the definitive choice when the performance and reliability of the component cannot be compromised.

Summary Table:

| Benefit | Description |

|---|---|

| Superior Mechanical Properties | High strength, hardness, and wear resistance due to minimal porosity |

| High Dimensional Accuracy | Near-net-shape parts with precise dimensions and low warping |

| Enhanced Material Integrity | Diffusion bonding without binders in vacuum/inert atmospheres |

| High Density | Near-total densification for improved performance |

Ready to elevate your manufacturing with high-performance hot pressing solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can bring superior mechanical properties, dimensional accuracy, and material integrity to your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?