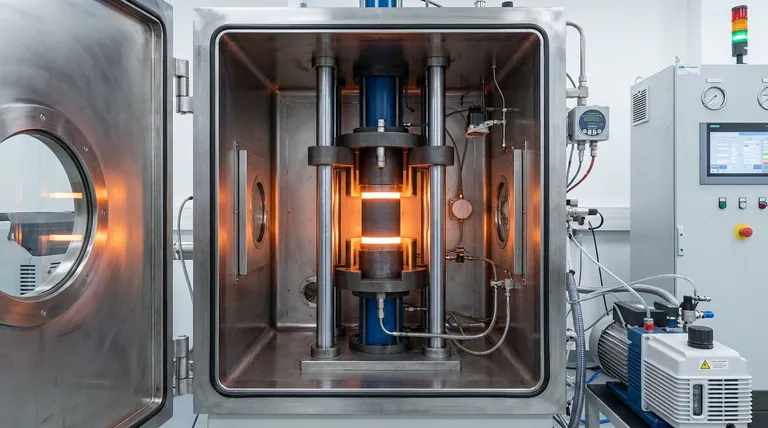

High-purity graphite molds function as the operative core of the Field Assisted Sintering Technology (FAST) process, serving simultaneously as the physical container for the material and the active engine for thermal energy. They are designed to constrain powder or chips under significant mechanical pressure while acting as a resistive heating element that converts electrical current directly into heat.

Core Takeaway: These molds consolidate two traditionally separate functions—the furnace heater and the pressure die—into a single component. This integration allows for the rapid, uniform application of thermal and mechanical energy, enabling fully dense sintering of materials that are often difficult to process.

The Dual-Function Mechanism

The efficiency of the FAST process relies on the graphite mold performing two distinct physical roles at the exact same time.

Resistive Heating Element

In conventional sintering, an external furnace heats the mold. In FAST, the graphite mold itself acts as the resistor.

When electrical current is applied, the mold converts this energy into thermal energy (Joule heating). This allows thermal energy to be generated intimately close to the sample, rather than radiating from a distance, resulting in rapid heating rates.

Mechanical Pressure Vessel

While generating heat, the mold must also act as a rigid container to define the shape of the final product.

The mold constrains the powder or chips, transmitting axial force from the system's hydraulic punches. According to standard specifications, high-purity graphite molds are designed to withstand pressures up to 35 MPa, ensuring the material is physically compressed during the heating phase.

Critical Role in Sintering Quality

Beyond basic containment and heating, the specific properties of high-purity graphite drive the quality of the final material.

Uniform Thermal Field Distribution

Achieving high density requires that every part of the sample reaches the same temperature at the same time.

High-purity graphite possesses excellent thermal conductivity. This ensures that the heat generated is distributed evenly across the entire sample area, preventing hot spots or thermal gradients that could lead to cracking or uneven densification.

Overcoming Diffusion Barriers

To create a solid material from powder, atoms must move (diffuse) across particle boundaries.

The combination of the mold's ability to transmit mechanical stress (pressure) and rapid thermal energy helps particles overcome these diffusion barriers. This facilitates "structural densification," allowing the material to reach full density more quickly than in pressure-less environments.

Understanding the Trade-offs

While high-purity graphite is the standard for FAST, it introduces specific constraints that you must manage.

Pressure Limitations

Graphite is strong, but it is not steel or tungsten carbide.

The primary limitation is its mechanical strength; typically, these molds are rated for pressures up to 35 MPa. Exceeding this limit to force higher density can result in catastrophic mold failure or fracture.

Chemical Reactivity

Graphite is carbon, which is chemically reactive at the high temperatures used in FAST (often exceeding 800 K).

There is a risk of the sample adhering to or reacting with the mold walls. To mitigate this, interfaces like graphite foil or boron nitride coatings are often required to act as diffusion barriers between the sample and the mold.

Making the Right Choice for Your Project

The specific design and usage of the graphite mold should align with your material goals.

- If your primary focus is Rapid Densification: Ensure the mold geometry is optimized to maximize current density and facilitate the quickest possible Joule heating.

- If your primary focus is Material Purity: Utilize appropriate liners (such as graphite paper or ceramic coatings) to prevent carbon contamination from the mold itself.

High-purity graphite molds are not passive containers; they are active, energy-converting tools that determine the speed, density, and integrity of your sintered material.

Summary Table:

| Feature | Role in FAST Process | Benefit to Material |

|---|---|---|

| Resistive Heating | Converts electrical current directly into Joule heat | Enables rapid heating rates and energy efficiency |

| Mechanical Containment | Functions as a rigid die for axial pressure (up to 35 MPa) | Facilitates structural densification and shape definition |

| Thermal Conductivity | Distributes heat uniformly across the sample | Prevents thermal gradients and ensures material consistency |

| High Purity | Minimizes contamination during high-temp cycles | Maintains chemical integrity of the sintered sample |

Elevate Your Material Research with KINTEK

Precision in Field Assisted Sintering (FAST) starts with the right equipment. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique sintering needs.

Whether you are processing difficult-to-dense powders or optimizing thermal gradients, our team provides the technical expertise and high-performance hardware required for success.

Ready to optimize your lab's performance? Contact us today to discuss your custom furnace requirements.

References

- Samuel Lister, Martin Jackson. A comparative study of microstructure and texture evolution in low cost titanium alloy swarf and powder recycled via FAST and HIP. DOI: 10.1177/02670836241277060

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why use Vacuum Hot Press (VHP) for ZnS Ceramics? Achieve Superior IR Transparency and Mechanical Strength

- Why must mold materials in FAST/SPS systems possess high mechanical strength? Ensuring Safety and Precision

- What is the primary objective of using Hot Isostatic Pressing (HIP) for L-PBF Ti-6Al-4V? Maximize Component Integrity

- What are the primary advantages of industrial SPS vs. vacuum hot-pressing for Ti-6Al-4V? Achieve Superior Microstructure

- What specific issues does uniaxial pressure solve during Cu/rGO sintering? Achieve Maximum Conductivity & Density

- What is the benefit of programmable multi-segment process control in hot press sintering furnaces for nano-copper?

- Why is an industrial hot press critical for lunar ceramic components? Achieve Maximum Density and Impact Resistance

- What is the working principle of a vacuum hot press sintering furnace? Master Dense Material Creation