At its core, a vacuum hot press sintering furnace is a specialized system that simultaneously applies three critical forces to a material: a high vacuum, intense heat, and direct mechanical pressure. It does this to compact and fuse powdered materials into a solid, dense mass at temperatures below their melting point, preventing the contamination and oxidation that would occur in open air.

The fundamental purpose of a vacuum hot press is not just to heat a material, but to physically force its particles together in a pristine, gas-free environment. This unique combination enables the creation of highly dense, high-performance materials that cannot be produced through heating or pressing alone.

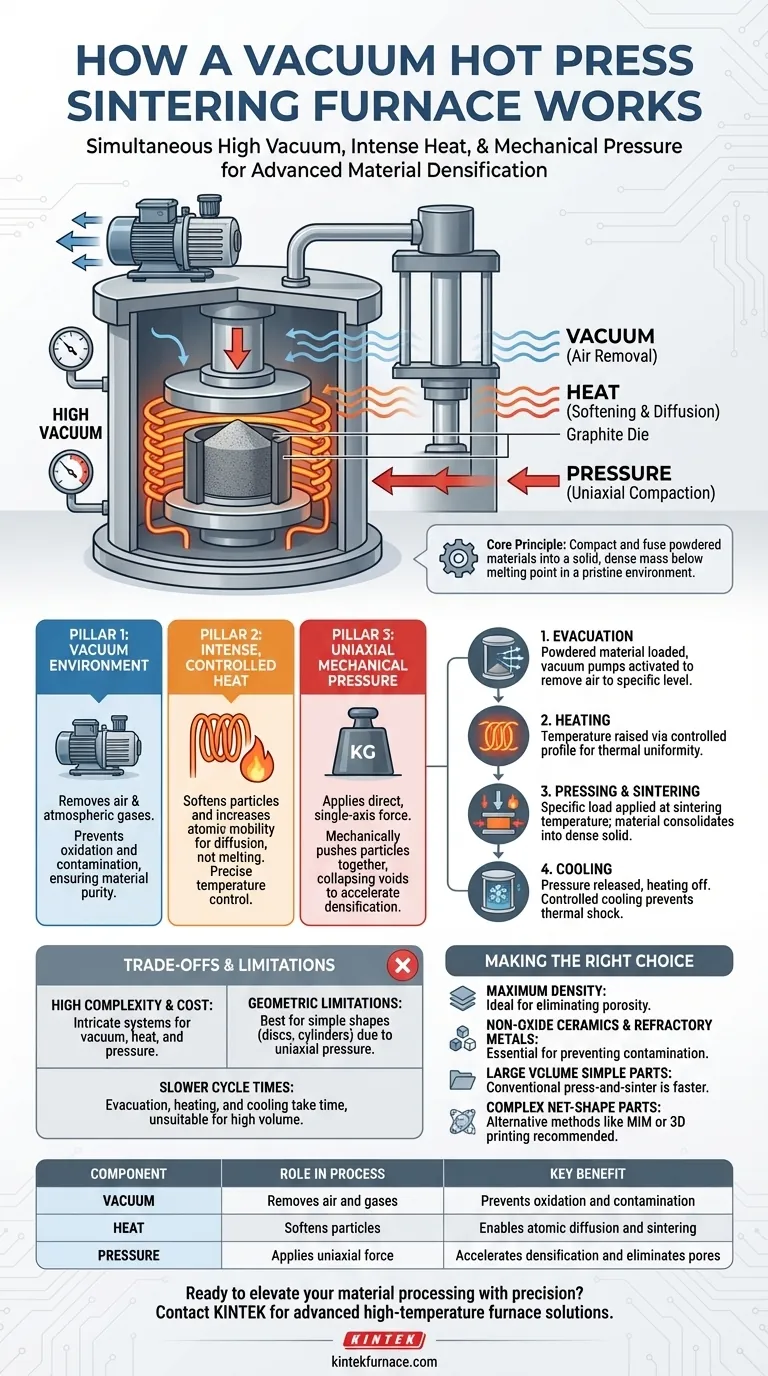

The Three Pillars of Hot Press Sintering

To understand the working principle, it is best to break it down into its three core components: the vacuum, the heat, and the pressure. Each element plays a distinct and critical role in the final outcome.

Pillar 1: The Vacuum Environment

A powerful vacuum system first removes air and other atmospheric gases from the furnace chamber. This is not an optional step; it is fundamental to the process.

The primary goal of the vacuum is to prevent oxidation and contamination. At high temperatures, most materials would instantly react with oxygen, forming unwanted chemical compounds and compromising the final product's integrity.

By creating a vacuum, the furnace ensures the material remains in its purest possible form throughout the heating and pressing cycle.

Pillar 2: Intense, Controlled Heat

Once the vacuum is established, heating elements—often using methods like medium-frequency induction heating—raise the temperature inside the chamber.

This heat is not intended to melt the material. Instead, it serves to soften the particles and increase atomic mobility. This softening makes the material pliable and encourages atoms to diffuse across the boundaries of adjacent particles, a key mechanism of sintering.

Precise temperature control is essential to reach the optimal sintering temperature without overshooting into the material's melting range.

Pillar 3: Uniaxial Mechanical Pressure

This is the "hot press" component that distinguishes this furnace from a standard vacuum sintering furnace. As the material reaches its target temperature, a hydraulic or mechanical press applies direct, uniaxial (single-axis) pressure.

This physical force dramatically accelerates the densification process. It mechanically pushes the softened particles together, collapsing the voids and pores between them. This is far more effective than relying on heat-induced diffusion alone.

The Step-by-Step Operational Process

The synergy of vacuum, heat, and pressure is managed in a precise, four-step sequence to ensure consistent and high-quality results.

Step 1: Evacuation

The material, typically in a powdered form within a graphite die, is placed inside the furnace. The vacuum pumps are activated to remove the air from the chamber until a specific vacuum level is achieved.

Step 2: Heating

The heating system is engaged, raising the material's temperature according to a pre-programmed profile. The rate of heating is carefully controlled to ensure thermal uniformity.

Step 3: Pressing & Sintering

At the designated sintering temperature, the press is activated, applying a specific load onto the material. The combination of high temperature and pressure is held for a set duration, during which the material consolidates into a dense solid.

Step 4: Cooling

After the sintering phase is complete, the pressure is released, and the heating system is turned off. The furnace cools down in a controlled manner, often assisted by a cooling system in the furnace walls, to prevent thermal shock and cracking in the newly formed part.

Understanding the Trade-offs and Limitations

While powerful, the vacuum hot press process is not universally applicable. Understanding its limitations is key to using it effectively.

High Equipment Complexity and Cost

These furnaces combine three complex systems—high vacuum, high temperature, and high pressure—making them significantly more expensive and intricate to operate and maintain than other types of furnaces.

Geometric Limitations

Because the pressure is applied along a single axis (uniaxial), the process is best suited for producing simple shapes like discs, cylinders, and rectangular blocks. Creating complex, three-dimensional geometries is not feasible.

Slower Cycle Times

The process is inherently slow. Achieving a deep vacuum, ramping up to temperature, holding for the press cycle, and controlled cooling all contribute to long cycle times, making it unsuitable for high-volume manufacturing.

Making the Right Choice for Your Application

Use this guidance to determine if a vacuum hot press is the correct tool for your specific material processing goal.

- If your primary focus is achieving maximum possible density: This is the ideal technology, as the mechanical pressure actively eliminates porosity better than heat-only methods.

- If your primary focus is processing non-oxide ceramics or refractory metals: The vacuum environment is non-negotiable for preventing contamination, and the press assists in densifying these difficult materials.

- If your primary focus is producing large volumes of simple metal parts: A conventional press-and-sinter operation in a belt furnace is likely a more cost-effective and faster solution.

- If your primary focus is creating complex, net-shape parts: You should investigate alternative methods like metal injection molding (MIM) or additive manufacturing (3D printing).

By understanding how these forces work together, you can make an informed decision on whether this advanced process is the right solution for your material challenge.

Summary Table:

| Component | Role in Process | Key Benefit |

|---|---|---|

| Vacuum | Removes air and gases | Prevents oxidation and contamination |

| Heat | Softens particles via controlled heating | Enables atomic diffusion and sintering |

| Pressure | Applies uniaxial mechanical force | Accelerates densification and eliminates pores |

Ready to elevate your material processing with precision? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're working with non-oxide ceramics, refractory metals, or other advanced materials, we can help you achieve superior density and performance. Contact us today to discuss how our vacuum hot press sintering furnaces can transform your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What is a vacuum hot press furnace? Unlock Superior Material Performance