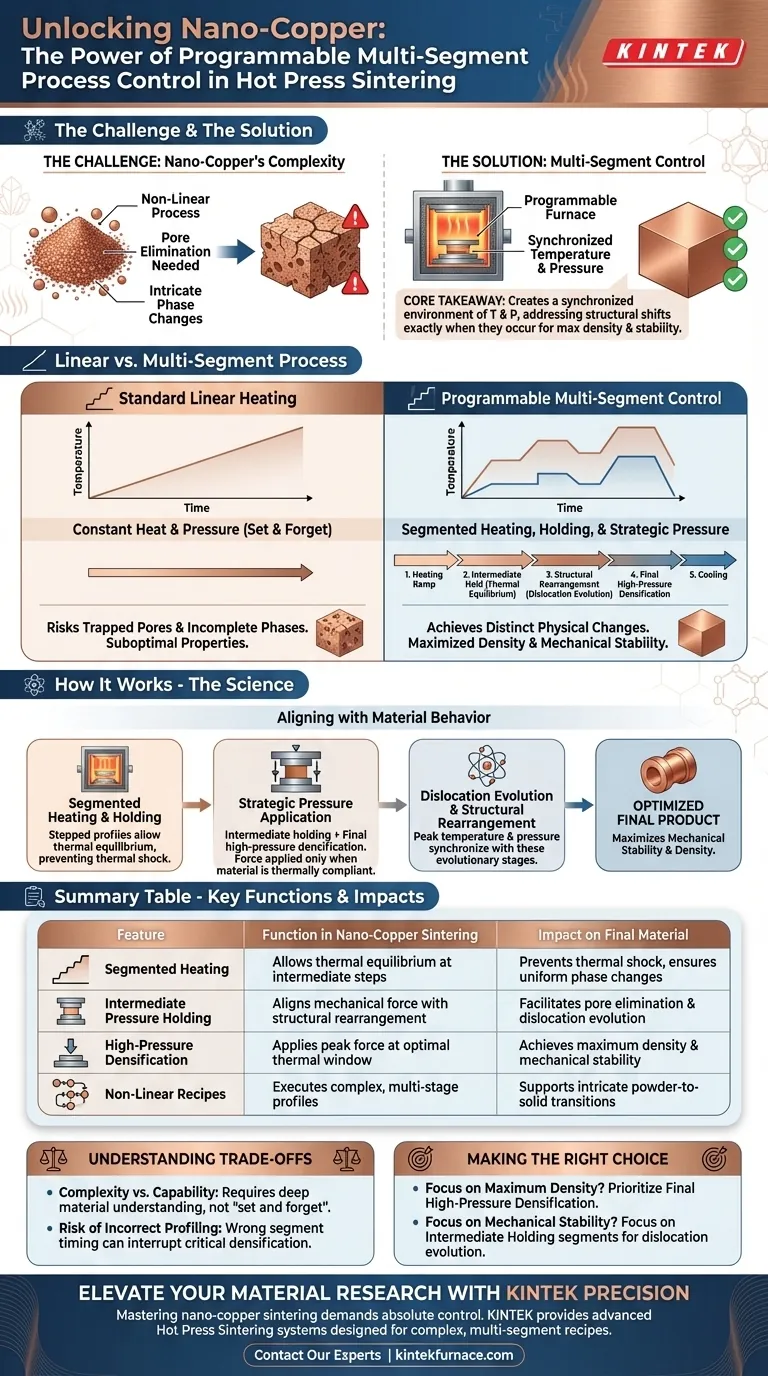

Programmable multi-segment process control is the defining feature that allows hot press sintering furnaces to successfully process nano-copper. It enables the execution of complex, non-linear recipes—specifically segmented heating, intermediate pressure holding, and final high-pressure densification—which are required to achieve distinct physical changes in the material that a standard linear heating ramp cannot support.

Core Takeaway Nano-copper sintering is not a linear process; it involves intricate phase changes and structural shifts. Multi-segment control creates a synchronized environment of temperature and pressure, maximizing material density and mechanical stability by addressing these shifts exactly when they occur.

The Engineering Challenge of Nano-Copper

Beyond Simple Heating

Nano-copper does not densify uniformly under constant heat. The material requires a dynamic approach to processing.

To transform nano-powder into a solid, stable component, the process must actively manage complex behaviors within the material structure.

Targeting Specific Physical Changes

The primary obstacles to high-quality sintering are pore elimination and phase changes.

If the furnace applies pressure or heat too early or too late, pores may become trapped, or the phase change may remain incomplete, compromising the final product.

How Multi-Segment Control Solves This

Segmented Heating and Holding

Programmable control allows for "stepped" heating profiles rather than a continuous ramp.

The furnace can hold the material at intermediate temperatures. This creates a window for thermal equilibrium before moving to the next critical stage of the process.

Strategic Pressure Application

Pressure is just as critical as temperature in this process. The technology enables intermediate holding with pressure, followed by final high-pressure densification.

This ensures that mechanical force is applied only when the material is thermally compliant enough to accept it without defect.

Aligning with Dislocation Evolution

At the microscopic level, the material undergoes dislocation evolution and structural rearrangement.

Programmable segments ensure that temperature and pressure peak specifically during these evolutionary stages. This synchronization is the key to maximizing the mechanical stability of the final part.

Understanding the Trade-offs

Complexity vs. Capability

The primary trade-off with programmable multi-segment furnaces is the complexity of process design.

Unlike simple sintering, where you "set and forget" a temperature, these furnaces require a deep understanding of the material's behavior.

The Risk of Incorrect Profiling

Because the furnace allows for complex paths, an incorrectly programmed segment can interrupt critical densification.

If the high-pressure stage is triggered before the structural rearrangement is ready, the material density will be suboptimal regardless of the machine's power.

Making the Right Choice for Your Goal

To leverage programmable control effectively, align your process parameters with your specific material objectives:

- If your primary focus is Maximum Density: Prioritize the final high-pressure densification segment to crush remaining pores after the heating phase.

- If your primary focus is Mechanical Stability: Focus on the intermediate holding segments to allow proper time for dislocation evolution and structural rearrangement.

Mastering the timing of these segments transforms nano-copper from a raw powder into a high-performance industrial material.

Summary Table:

| Feature | Function in Nano-Copper Sintering | Impact on Final Material |

|---|---|---|

| Segmented Heating | Allows thermal equilibrium at intermediate steps | Prevents thermal shock and ensures uniform phase changes |

| Intermediate Pressure Holding | Aligns mechanical force with structural rearrangement | Facilitates pore elimination and dislocation evolution |

| High-Pressure Densification | Applies peak force at the optimal thermal window | Achieves maximum density and mechanical stability |

| Non-Linear Recipes | Executes complex, multi-stage process profiles | Supports intricate physical transitions powder-to-solid |

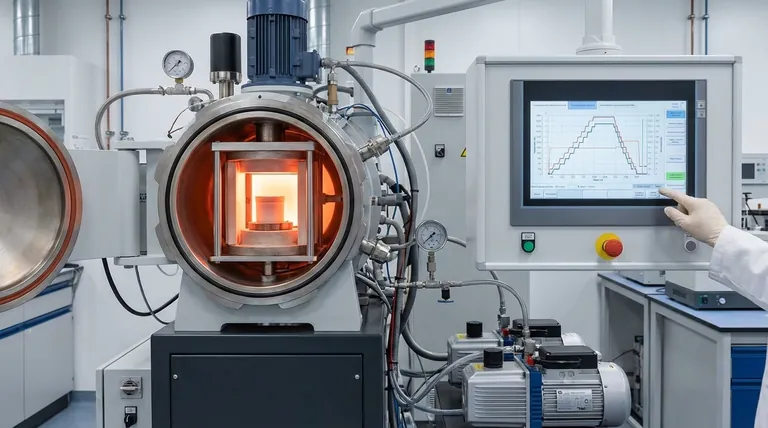

Elevate Your Material Research with KINTEK Precision

Mastering nano-copper sintering requires more than just heat—it demands absolute control. At KINTEK, we provide advanced Hot Press Sintering systems and customizable Muffle, Tube, and Vacuum furnaces designed to execute complex, multi-segment recipes with surgical precision.

Backed by expert R&D and world-class manufacturing, our systems are tailored to meet the unique challenges of structural rearrangement and high-pressure densification. Ready to optimize your sintering profile?

Contact our technical experts today to find your custom solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What effect does mechanical pressure have on AZ31/UCF/AZ31 composite formation? Master VHP Densification

- Why is a vacuum environment required in a vacuum hot pressing sintering furnace when preparing ceramic tools containing metal binders? Achieve Purity for Superior Tool Performance

- What is the key principle of a hot press sintering furnace? Achieve Superior Densification for High-Performance Materials

- What are the primary applications of vacuum hot press furnaces? Achieve Superior Material Density and Purity

- How does an industrial-grade hot press sintering system benefit Al2O3/TiC/SiC(w) ceramics? Enhanced Material Density

- What types of advanced materials can be prepared using a vacuum press? Unlock High-Performance Fabrication

- What are the advantages of using a vacuum hot pressing furnace compared to explosive cladding? Get Precision Results

- What role do vacuum hot press furnaces play in advanced materials development? Forge High-Density, Pure Materials