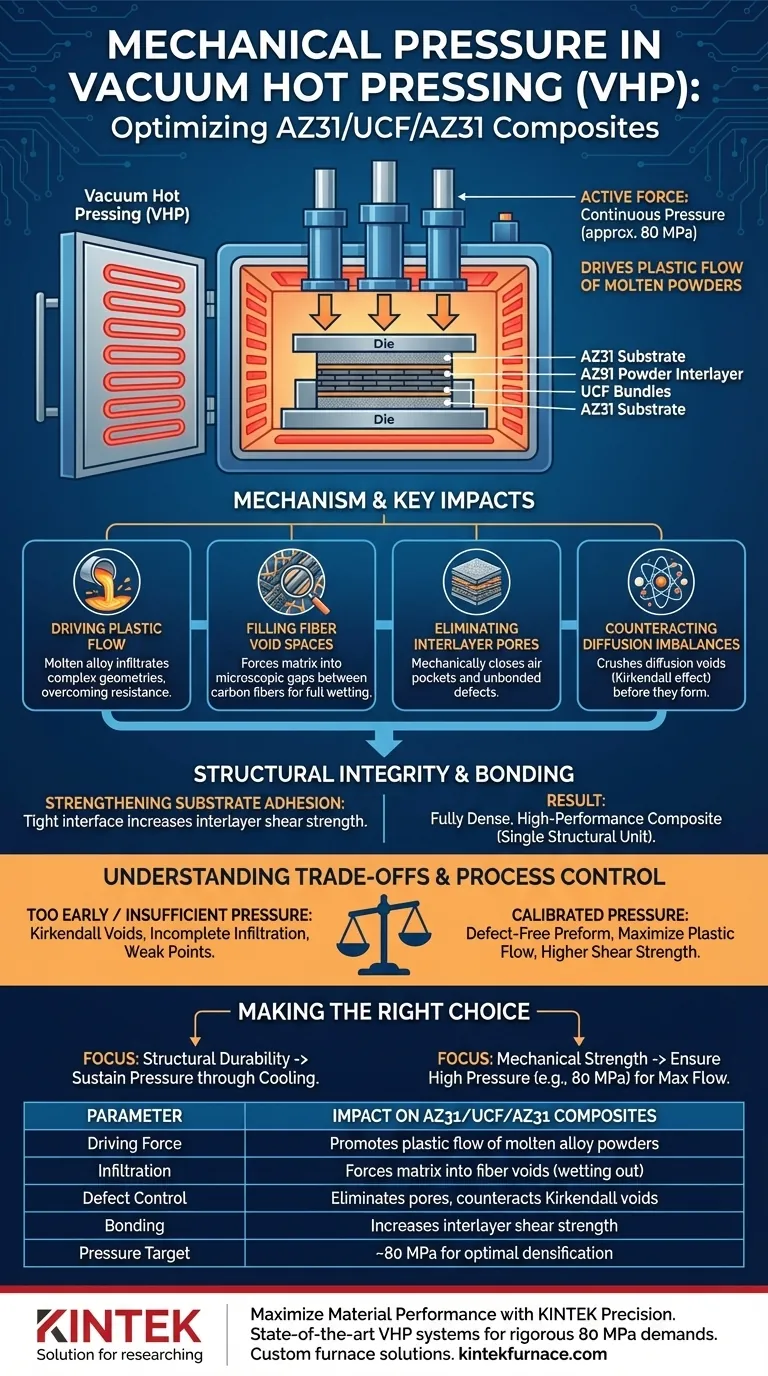

Mechanical pressure is the active force responsible for densification during the Vacuum Hot Pressing (VHP) of AZ31/UCF/AZ31 composites. By applying continuous pressure (specifically around 80 MPa), the process drives the plastic flow of molten alloy powders (such as AZ91), compelling them to infiltrate carbon fiber bundles and eliminate structural defects.

Core Takeaway

The application of mechanical pressure is not merely for holding components together; it is a critical processing parameter that forces the impregnation of fiber bundles and counteracts porosity. This results in a fully dense composite with significantly higher interlayer shear strength than could be achieved through heating alone.

The Mechanism of Infiltration and Flow

Driving Plastic Flow

In a VHP furnace, heat alone is often insufficient to fully consolidate composite layers. The mechanical pressure promotes the plastic flow of the molten alloy powders (often used as an interlayer) situated between the structural components.

This forced flow is essential for moving material into complex geometries that gravity or capillary action cannot reach.

Filling Fiber Void Spaces

The most critical challenge in creating Carbon Fiber (UCF) composites is "wetting out" the fibers. The applied pressure forces the molten matrix to fully fill the microscopic voids between individual carbon fiber bundles.

Without this external force, surface tension would prevent the alloy from penetrating the fiber weave, resulting in "dry" spots and weak points.

Structural Integrity and Bonding

Eliminating Interlayer Pores

As materials are heated, atomic diffusion and volume expansion can create gaps. The continuous pressure acts to eliminate interlayer pores and unbonded defects that naturally form during the layering process.

By compressing the stack, the furnace ensures that any potential air pockets or gaps caused by surface irregularities are mechanically closed.

Counteracting Diffusion Imbalances

At the atomic level, diffusion rates between different materials can vary (e.g., the Kirkendall effect), potentially leading to void formation.

Mechanical pressure actively counteracts porosity caused by these atomic diffusion imbalances. It forces particles into such close contact that diffusion voids are crushed before they can compromise the material's integrity.

Strengthening Substrate Adhesion

The pressure ensures a tight, continuous interface between the reinforced layer and the solid AZ31 substrate.

This intimate contact is directly responsible for increasing the interlayer shear strength, ensuring the composite behaves as a single structural unit rather than a stack of loosely bonded plates.

Understanding the Trade-offs

The Necessity of Process Control

While pressure is beneficial, it must be carefully calibrated. The goal is to create a defect-free preform, but the pressure is specifically acting to overcome resistance to flow.

If pressure is removed too early or is insufficient, the material may suffer from Kirkendall voids or incomplete infiltration. Conversely, the process relies on the presence of a molten phase (like AZ91 powder) to facilitate this flow; pressure applied to purely solid-state materials without adequate heat would not achieve the same infiltration of the fiber bundles.

Making the Right Choice for Your Goal

The role of pressure in VHP is multifaceted. Depending on your specific performance requirements, you should view the pressure parameter through different lenses:

- If your primary focus is Structural Durability: Prioritize sustaining pressure throughout the cooling phase to prevent the reopening of pores or the formation of diffusion voids.

- If your primary focus is Mechanical Strength: Ensure the pressure is high enough (e.g., 80 MPa) to maximize plastic flow, as this directly correlates to higher interlayer shear strength.

Ultimately, mechanical pressure transforms the assembly from a loose stack of materials into a fully dense, high-performance composite.

Summary Table:

| Parameter | Impact on AZ31/UCF/AZ31 Composites |

|---|---|

| Driving Force | Promotes plastic flow of molten alloy powders (e.g., AZ91) |

| Infiltration | Forces matrix into microscopic carbon fiber voids (wetting out) |

| Defect Control | Eliminates interlayer pores and counteracts Kirkendall voids |

| Bonding | Increases interlayer shear strength through intimate substrate contact |

| Pressure Target | ~80 MPa required for optimal densification and structural integrity |

Maximize Material Performance with KINTEK Precision

Achieving full densification in complex AZ31 composites requires the exact balance of heat and mechanical pressure. KINTEK provides state-of-the-art Vacuum Hot Pressing (VHP) systems designed to handle rigorous demands like 80 MPa infiltration processes.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique research or production needs. Whether you are developing aerospace-grade composites or high-temp lab samples, our equipment ensures uniform heating and precise pressure control.

Ready to eliminate structural defects in your composites? Contact KINTEK today to discuss your custom furnace solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a precision pressure control system assist in material formation during Eutectic Bonding?

- What is the purpose of performing high-temperature degassing in a vacuum furnace before the hot pressing of Al-Cu alloy powders? Ensure Maximum Density and Strength

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What is a vacuum hot press and what is its primary function? Unlock Advanced Materials Processing

- What are the key advantages of vacuum hot press furnaces compared to conventional furnaces? Achieve Superior Purity and Control

- Why is a high vacuum required in a hot-pressing furnace? Achieve Perfect Transparency in Fluoride Ceramics

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What are the common applications of hot press furnaces? Unlock High-Density Material Solutions