At its core, a hot press furnace is used for a range of specialized applications including powder metallurgy, advanced ceramic processing, composite material fabrication, and novel materials research. These furnaces are uniquely capable of simultaneously applying high temperature and immense pressure in a controlled atmosphere, enabling the creation of highly dense, high-performance materials.

The true value of a hot press furnace isn't just its ability to heat materials, but its power to compress them at the same time. This dual-action process is the key to producing fully dense components with superior mechanical properties that are unattainable through heat-only methods like conventional sintering.

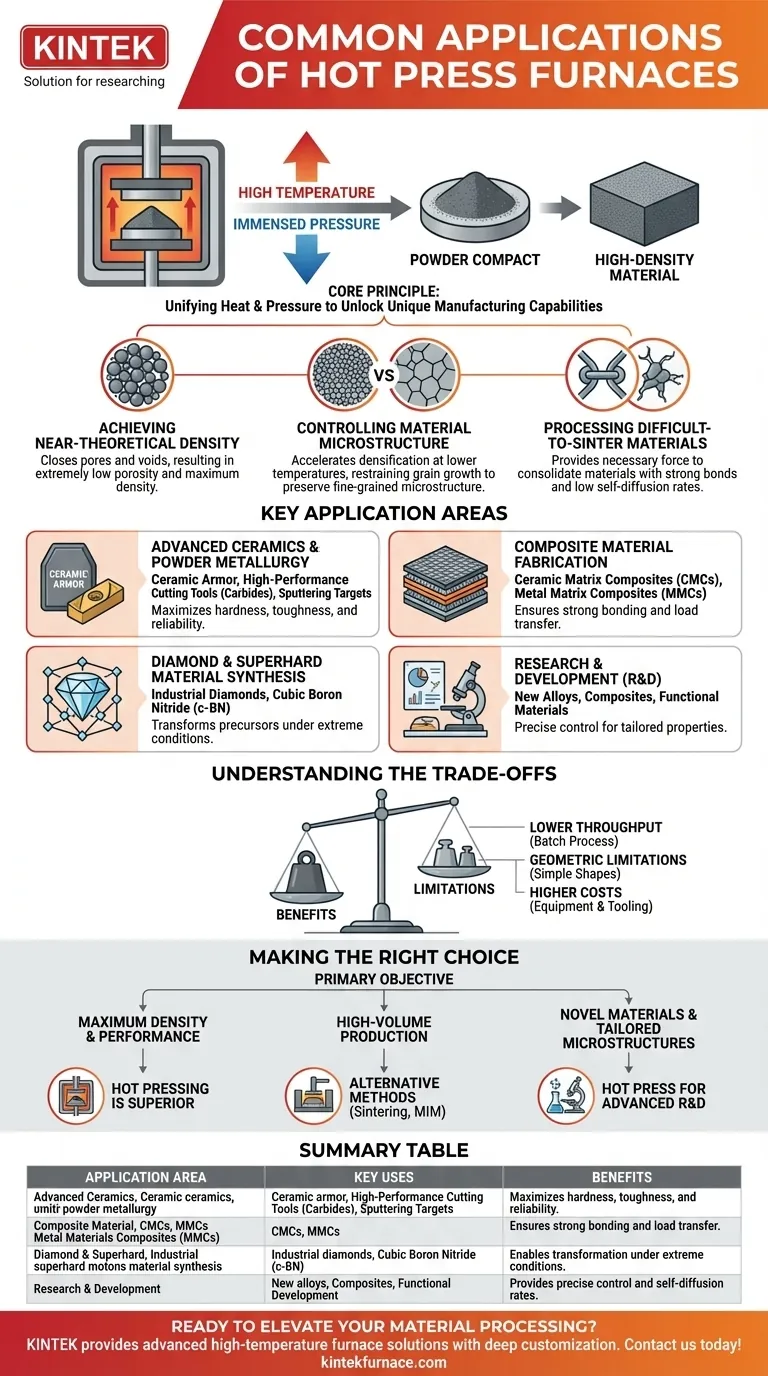

The Core Principle: Unifying Heat and Pressure

The defining characteristic of hot pressing is the simultaneous application of thermal and mechanical energy. This fundamental principle is what unlocks its unique manufacturing capabilities.

Achieving Near-Theoretical Density

During the process, external pressure is applied to a powder compact while it is heated. This force physically closes the pores and voids between particles.

The result is a final product with extremely low porosity and a density that approaches the theoretical maximum for that material.

Controlling Material Microstructure

Conventional sintering can lead to unwanted crystal grain growth as materials are held at high temperatures for long periods. This can degrade mechanical properties.

Hot pressing accelerates the densification process, allowing for lower temperatures or shorter cycle times. This effectively restrains grain growth, preserving the fine-grained microstructure essential for high-strength materials like nanometer-scale ceramics.

Processing Difficult-to-Sinter Materials

Many advanced materials, such as non-oxide ceramics and certain metal alloys, have strong covalent bonds and low self-diffusion rates.

These materials resist densification by heat alone. The addition of pressure in a hot press provides the necessary driving force to consolidate them effectively.

Key Application Areas in Detail

Understanding the core principle reveals why hot pressing is the chosen method for demanding applications where material performance is non-negotiable.

Advanced Ceramics and Powder Metallurgy

This is the most common application area. Hot pressing is used to produce components like ceramic armor, high-performance cutting tools (carbides), and sputtering targets.

In these fields, any internal porosity is a potential failure point. The pressure applied during hot pressing ensures a fully consolidated part, maximizing hardness, toughness, and reliability.

Composite Material Fabrication

Hot pressing is critical for manufacturing composite materials, especially Ceramic Matrix Composites (CMCs) and Metal Matrix Composites (MMCs).

The process ensures intimate contact and strong bonding between the matrix material (e.g., ceramic or metal) and the reinforcing fibers or particles. This is essential for effective load transfer within the composite structure.

Diamond and Superhard Material Synthesis

The synthesis of industrial diamonds and other superhard materials like cubic boron nitride (c-BN) requires extreme conditions.

Hot press furnaces provide the combination of high temperature and high pressure needed to transform precursor materials (like graphite) into these superhard crystalline structures.

Research and Development (R&D)

For materials scientists, the hot press is an indispensable research tool. It allows for the exploration and development of new alloys, composites, and functional materials.

The precise control over temperature, pressure, and atmosphere (vacuum or inert gas) enables researchers to systematically study densification behavior and create novel materials with tailored properties for academic and industrial purposes.

Understanding the Trade-offs

While powerful, hot pressing is not a universal solution. Its benefits must be weighed against its inherent limitations.

Lower Throughput and Cycle Times

Hot pressing is typically a batch process, not a continuous one. The time required for heating, pressing, and cooling a single component or a small batch of components is significantly longer than for many high-volume manufacturing methods.

Geometric Limitations

The final component shape is constrained by the geometry of the die and punch assembly. Complex, intricate shapes are difficult or impossible to produce directly and may require extensive post-process machining.

Higher Equipment and Tooling Costs

Hot press furnaces are complex, specialized machines. The initial capital investment is high, and the graphite or ceramic dies used in the process are expensive consumables with a limited lifespan, especially under extreme conditions.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on your project's primary objective.

- If your primary focus is maximum density and material performance: Hot pressing is the superior choice for consolidating materials that are difficult to sinter and where any porosity is unacceptable.

- If your primary focus is high-volume production of less-critical parts: Alternative methods like conventional sintering, press-and-sinter, or metal injection molding are likely more cost-effective.

- If your primary focus is creating novel materials with tailored microstructures: The precise process control offered by a hot press furnace makes it an essential tool for advanced research and development.

Ultimately, understanding that a hot press furnace fundamentally offers control over density is the key to leveraging its power effectively.

Summary Table:

| Application Area | Key Uses | Benefits |

|---|---|---|

| Advanced Ceramics & Powder Metallurgy | Ceramic armor, cutting tools, sputtering targets | Maximizes hardness, toughness, and reliability with full densification |

| Composite Material Fabrication | CMCs, MMCs | Ensures strong bonding and load transfer for enhanced structural integrity |

| Diamond & Superhard Material Synthesis | Industrial diamonds, cubic boron nitride | Enables transformation under extreme temperature and pressure conditions |

| Research & Development | New alloys, composites, functional materials | Provides precise control for tailored properties and academic studies |

Ready to elevate your material processing with precision and performance? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our hot press furnaces can deliver superior density and tailored solutions for your specific needs!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity