High-temperature degassing is a mandatory purification step designed to strip volatile contaminants from the surface of Al-Cu powder particles prior to consolidation. Its immediate purpose is to remove moisture, adsorbed gases, and residues from process control agents that would otherwise become trapped inside the material.

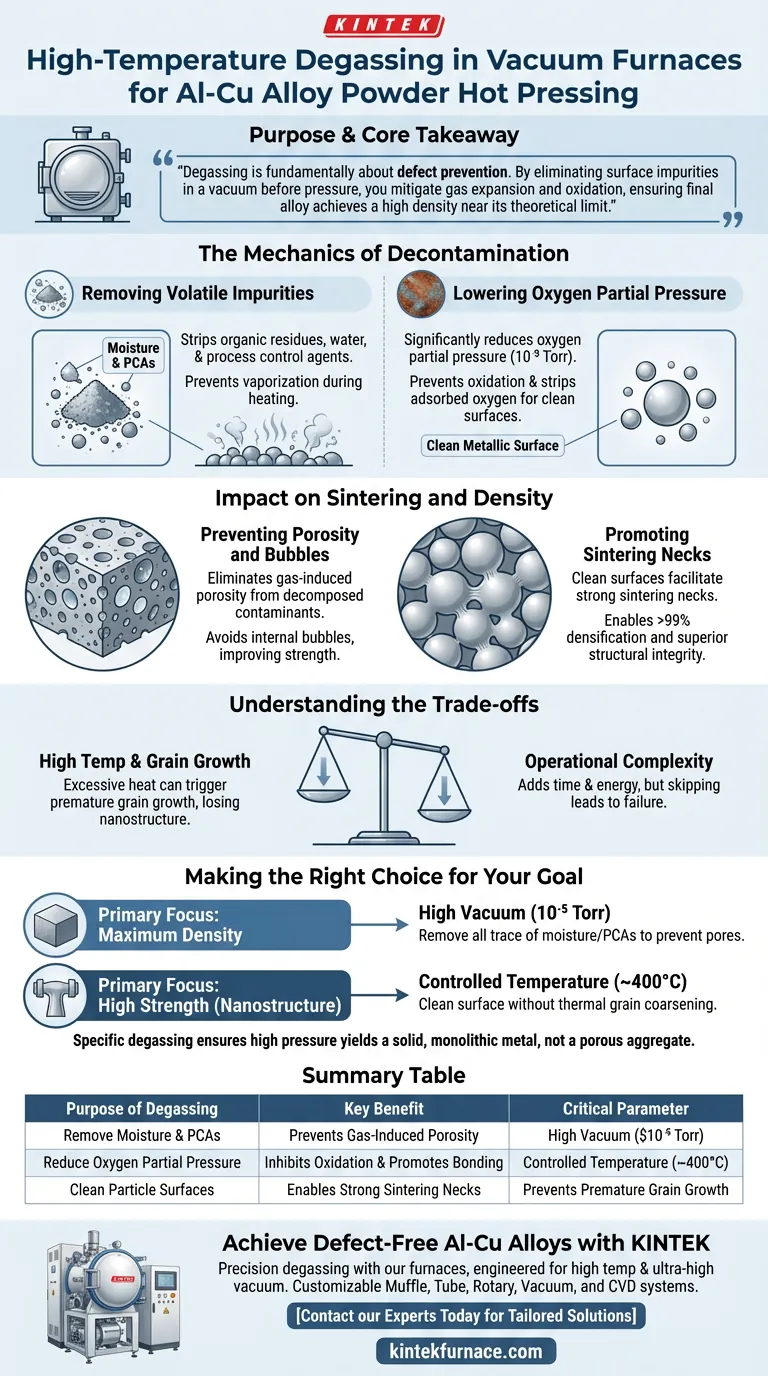

The Core Takeaway Degassing is fundamentally about defect prevention. By eliminating surface impurities in a vacuum before pressure is applied, you mitigate the risk of gas expansion and oxidation, ensuring the final alloy achieves a high density near its theoretical limit.

The Mechanics of Decontamination

Removing Volatile Impurities

Metal powders, particularly those processed via ball milling, often retain process control agents (PCAs) and environmental moisture on their surfaces.

If these organic residues and water molecules are not removed, they will vaporize during the heating phase of hot pressing.

Degassing at temperatures (e.g., 400°C) allows these volatiles to desorb and be evacuated by the vacuum system before the powder is compacted.

Lowering Oxygen Partial Pressure

Aluminum and copper are susceptible to oxidation, which creates brittle boundary layers between particles.

A vacuum environment (e.g., $10^{-5}$ Torr) significantly reduces the oxygen partial pressure.

This prevents further oxidation of the metal powder and aids in stripping existing adsorbed oxygen, leaving a clean metallic surface ready for bonding.

Impact on Sintering and Density

Preventing Porosity and Bubbles

The most critical deep need addressed by degassing is the prevention of gas-induced porosity.

If contaminants remain on the powder during the high-pressure consolidation phase, they decompose into gases that get trapped inside the solidifying metal.

This results in internal bubbles or pores that drastically reduce the mechanical strength and fatigue life of the final component.

Promoting Sintering Necks

High-density consolidation requires particles to diffuse into one another effectively.

Clean, degassed surfaces facilitate the formation of strong sintering necks between particles.

This direct metal-to-metal contact allows the material to achieve densification levels over 99%, ensuring superior structural integrity.

Understanding the Trade-offs

Balancing Temperature and Grain Growth

While high temperatures are necessary to remove stubborn impurities, excessive heat prior to pressing can be detrimental.

Extended exposure to high heat during degassing can trigger premature grain growth, causing the material to lose its nanocrystalline structure before it is even pressed.

Operational Complexity

Adding a dedicated degassing cycle increases total processing time and energy consumption.

However, skipping this step to save time almost invariably leads to structural failure due to blistering or low density in the final part.

Making the Right Choice for Your Goal

To optimize your Al-Cu alloy production, align your process parameters with your specific performance targets:

- If your primary focus is Maximum Density: Ensure the vacuum level is high ($10^{-5}$ Torr or better) to remove every trace of moisture and PCA residue, preventing pore formation.

- If your primary focus is High Strength (Nanostructure): Keep the degassing temperature strictly controlled (around 400°C) to clean the surface without triggering thermal grain coarsening.

Ultimately, specific degassing ensures that the high pressure applied later yields a solid, monolithic metal rather than a porous, brittle aggregate.

Summary Table:

| Purpose of Degassing | Key Benefit | Critical Parameter |

|---|---|---|

| Remove Moisture & PCAs | Prevents Gas-Induced Porosity | High Vacuum (e.g., 10⁻⁵ Torr) |

| Reduce Oxygen Partial Pressure | Inhibits Oxidation & Promotes Bonding | Controlled Temperature (e.g., 400°C) |

| Clean Particle Surfaces | Enables Strong Sintering Necks | Prevents Premature Grain Growth |

Achieve Defect-Free Al-Cu Alloys with KINTEK

Perfecting your hot pressing process starts with precise degassing. Our vacuum furnaces are engineered to deliver the critical combination of high temperature and ultra-high vacuum necessary to remove volatile contaminants, prevent porosity, and ensure your materials achieve maximum density and strength.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for unique needs like nanostructure preservation in Al-Cu alloys.

Let's optimize your materials process. Contact our experts today for a solution tailored to your research and production goals.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the primary function of a vacuum hot press furnace in the preparation of Fe-based amorphous alloy/aluminum microlaminated composites? Achieve Perfect Solid-State Bonding

- What role does a laboratory hydraulic press play in forming BCZT powder? Achieve Precise 10mm Green Compacts

- How does the high-precision temperature control system of a sintering furnace influence nano-copper microstructure?

- How are vacuum hot pressing sintering furnaces classified based on their operating temperature? A Guide to Low, Medium, and High-Temp Ranges

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing

- Why is a high vacuum environment crucial when preparing copper-carbon nanotube composites in a vacuum hot press furnace? Achieve Superior Composite Integrity

- What advantages does a vacuum hot press furnace demonstrate for Fe-Cu-Ni-Sn-VN composites? Superior Nanostructure Prep

- Why is vacuum press technology indispensable in modern metalworking? Unlock Precision and Quality in Metal Forming