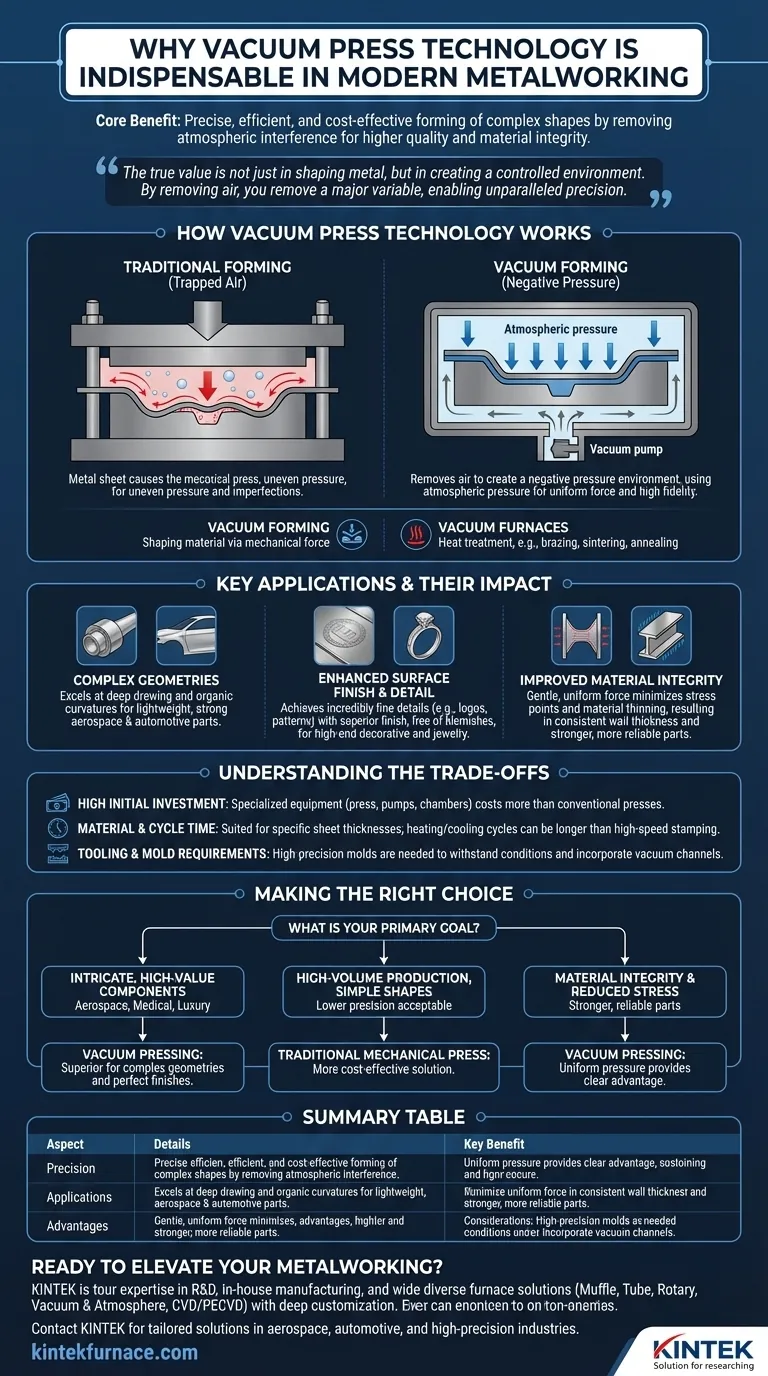

At its core, vacuum press technology is indispensable in modern metalworking because it allows for the precise, efficient, and cost-effective forming of metals into complex shapes. By removing air from the process, it eliminates atmospheric interference, leading to higher quality components, enhanced material integrity, and the ability to produce designs that are impossible with traditional mechanical methods.

The true value of vacuum press technology is not just in shaping metal, but in creating a controlled environment. By removing air, you remove a major variable, enabling a level of precision and detail that conventional stamping or pressing cannot achieve.

How Vacuum Press Technology Works

The Principle of Unopposed Force

In traditional metal forming, you are not just fighting the material's resistance; you are also fighting the air trapped between the tool and the workpiece. This trapped air can cause imperfections, limit detail, and create uneven pressure.

Vacuum press technology solves this by removing the air from the equation entirely. This creates a negative pressure environment where the metal can be drawn into a mold with uniform force, free from atmospheric contamination or resistance.

The Core Forming Mechanism

The process is elegant in its simplicity. A sheet of metal, often heated to increase its malleability, is placed over a mold within a sealed chamber.

A powerful vacuum pump then evacuates the air from the chamber. The resulting atmospheric pressure outside the sheet then acts as a massive, perfectly distributed clamp, pushing the metal onto the mold and forcing it to conform to every detail with exceptional fidelity.

Distinguishing from Vacuum Furnaces

It is important to distinguish vacuum forming from vacuum heat treatment. While both use a vacuum, their purpose is different.

Vacuum furnaces are used for processes like brazing, sintering, and annealing, where the vacuum prevents oxidation and contamination during high-temperature thermal cycles. A vacuum press, in contrast, uses the vacuum as the primary mechanical force for shaping the material.

Key Applications and Their Impact

Achieving Complex Geometries

Vacuum technology excels at deep drawing and forming parts with complex, organic curvatures. This is critical in the aerospace and automotive industries for creating aerodynamic body panels, turbine components, and intricate structural elements that are both lightweight and strong.

Enhancing Surface Finish and Detail

The uniform pressure of a vacuum press allows for incredibly fine detail work, such as embossing logos or patterns onto metal surfaces.

Because there is no trapped air to cause bubbles or blemishes, the resulting surface finish is superior. This makes it a vital tool in producing high-end decorative components and even fine jewelry.

Improving Material Integrity

Mechanical stamping can create high-stress points and cause uneven material thinning. The gentle, uniform force applied in a vacuum press minimizes these issues.

This results in a finished part with more consistent wall thickness and improved structural integrity, reducing the risk of weak spots or premature failure.

Understanding the Trade-offs

High Initial Investment

Vacuum press systems are specialized pieces of equipment. The initial capital outlay for the press, vacuum pumps, and sealed chambers is typically higher than for conventional mechanical presses.

Material and Cycle Time Considerations

The process is best suited for sheet metals of a certain thickness range. Very thick plates may not be practical to form with vacuum pressure alone.

Additionally, the cycle of heating, forming, and cooling can be longer than that of high-speed mechanical stamping, making it less ideal for extremely high-volume production of simple parts where precision is secondary to speed.

Tooling and Mold Requirements

Creating the molds, or "tools," for vacuum pressing requires high precision. The mold must be able to withstand the forming temperatures and pressures while also incorporating channels for the vacuum to be pulled effectively.

Making the Right Choice for Your Goal

When evaluating vacuum press technology, your decision should be driven by the specific demands of your final product.

- If your primary focus is intricate, high-value components: Vacuum pressing is the superior choice for achieving complex geometries and perfect surface finishes, essential for aerospace, medical, or luxury goods.

- If your primary focus is high-volume production of simple shapes: A traditional high-speed mechanical press may be a more cost-effective solution, assuming the lower level of precision is acceptable.

- If your primary focus is material integrity and reduced stress: The uniform pressure of a vacuum press provides a clear advantage, resulting in stronger, more reliable parts compared to stamping.

Ultimately, adopting vacuum press technology is a strategic decision to prioritize quality and unlock new design possibilities.

Summary Table:

| Aspect | Details |

|---|---|

| Key Benefit | Enables precise forming of complex shapes with uniform pressure, eliminating atmospheric interference. |

| Applications | Aerospace, automotive, jewelry, and decorative components for deep drawing and fine detail work. |

| Advantages | Superior surface finish, improved material integrity, reduced stress points, and ability to produce intricate designs. |

| Considerations | Higher initial investment, longer cycle times for heating/cooling, and precise mold requirements. |

Ready to elevate your metalworking with advanced vacuum press solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs.

Whether you're in aerospace, automotive, or other high-precision industries, our vacuum press technology can help you achieve superior quality, complex geometries, and enhanced material integrity. Don't let design limitations hold you back—contact us today to discuss how we can tailor a solution for your specific goals!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What are the typical operational steps when using a vacuum press? Master Flawless Bonding and Forming

- How does automation enhance the hot pressing process? Boost Precision, Efficiency, and Quality

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies