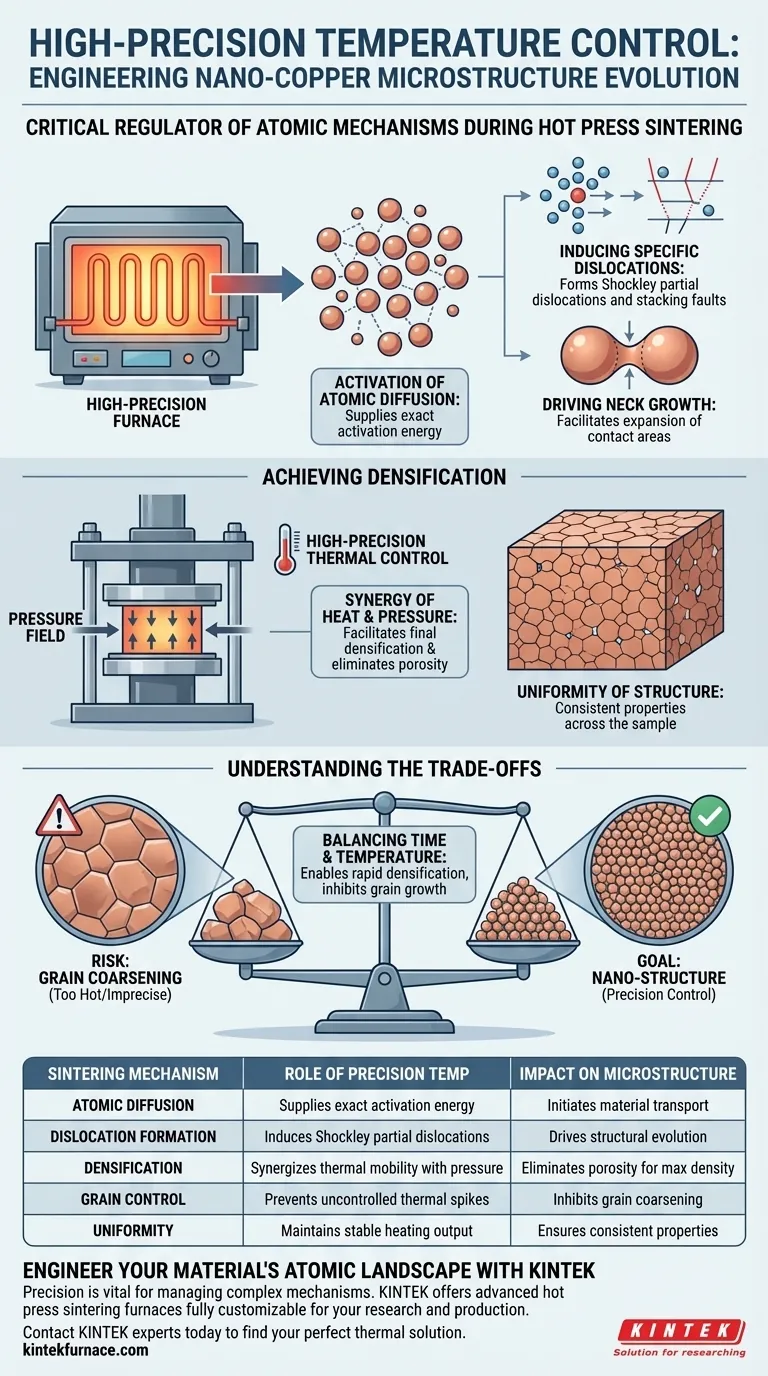

High-precision temperature control acts as the critical regulator of atomic mechanisms during the sintering of nano-copper. It ensures the delivery of the exact activation energy required to induce specific atomic defects—namely Shockley partial dislocations and stacking faults—which are the primary drivers for particle bonding and densification.

By maintaining a stable thermal environment, the system creates the precise conditions needed for atomic diffusion and dislocation slip. This allows for the rapid expansion of contact areas between particles (neck growth) while preventing the uncontrolled thermal spikes that ruin nano-scale structures.

The Mechanisms of Microstructure Evolution

Activation of Atomic Diffusion

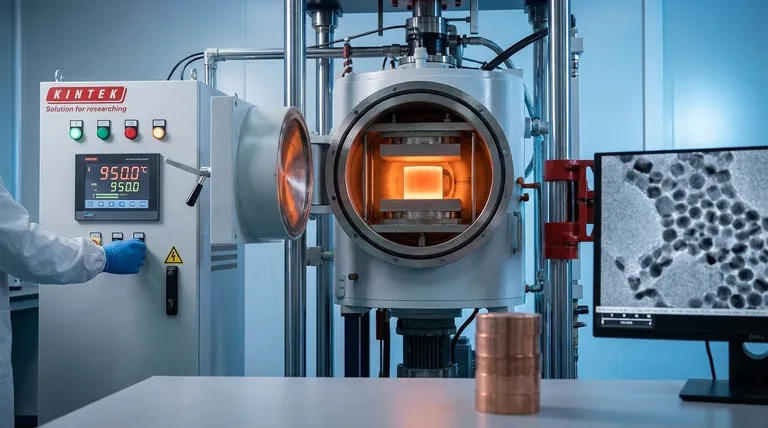

A high-precision furnace provides a stable high-temperature environment that is essential for overcoming the energy barrier of solid-state reactions.

This thermal stability supplies sufficient activation energy to the copper atoms. Once this energy threshold is met, atomic diffusion and dislocation slip mechanisms are activated, allowing material transport to begin.

Inducing Specific Dislocation Types

The quality of the temperature control directly influences the type of crystalline defects formed.

Specifically, precise thermal input induces the formation of Shockley partial dislocations and stacking faults. According to technical analysis, these specific defects dominate the initial stages of sintering, rather than random or chaotic deformation.

Driving Neck Growth

The evolution of the microstructure is visible through the interaction of copper particles.

The dislocations and stacking faults generated by the thermal environment facilitate the growth of particle contact necks. This expansion of the contact area is the physical manifestation of the sintering process, bridging the gaps between individual nano-particles.

Achieving Densification

The Synergy of Heat and Pressure

In a hot press sintering setup, temperature does not work in isolation.

The high-precision thermal control facilitates the final densification process alongside the applied pressure field. While pressure forces particles together, the thermally induced atomic mobility ensures they chemically bond and eliminate porosity.

Uniformity of Structure

Fluctuations in temperature can lead to uneven sintering or localized defects.

The monitoring system, utilizing sensors and feedback controllers, ensures the heating element output matches the set value exactly. This consistency is vital for maintaining a uniform microstructure across the entire copper sample.

Understanding the Trade-offs

The Risk of Grain Coarsening

While high temperatures are necessary for densification, they pose a specific threat to nano-materials: grain growth.

If the temperature control drifts too high or lacks precision, it triggers recrystallization reactions and excessive grain growth. This converts the desirable "nano" structure into a coarse microstructure, degrading the mechanical properties of the final composite.

Balancing Time and Temperature

A vacuum hot press system leverages precision to balance these competing factors.

By enabling rapid densification at the lowest effective temperatures, the system inhibits grain growth. High-precision control is what allows operators to walk the fine line between insufficient bonding (too cool) and the loss of nano-structure (too hot).

Making the Right Choice for Your Goal

To optimize the sintering of nano-copper, you must align your thermal strategy with your material performance targets.

- If your primary focus is Maximum Density: Prioritize thermal stability to ensure the continuous generation of Shockley partial dislocations for void elimination.

- If your primary focus is Maintaining Nano-Structure: Utilize the precision control to minimize the sintering temperature and duration to strictly inhibit grain growth.

High-precision temperature control is not merely about heating; it is about surgically applying energy to engineer the atomic landscape of your material.

Summary Table:

| Sintering Mechanism | Role of High-Precision Temperature | Impact on Microstructure |

|---|---|---|

| Atomic Diffusion | Supplies exact activation energy | Initiates material transport and particle bonding |

| Dislocation Formation | Induces Shockley partial dislocations | Drives neck growth and structural evolution |

| Densification | Synergizes thermal mobility with pressure | Eliminates porosity for maximum material density |

| Grain Control | Prevents uncontrolled thermal spikes | Inhibits grain coarsening to maintain nano-scale structure |

| Uniformity | Maintains stable heating element output | Ensures consistent properties across the entire sample |

Engineer Your Material's Atomic Landscape with KINTEK

Precision is the difference between a high-performance nano-composite and a failed experiment. At KINTEK, we understand that high-precision temperature control is vital for managing complex atomic mechanisms like Shockley partial dislocations and grain growth inhibition.

Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, including high-performance hot press sintering furnaces. Our lab high-temperature solutions are fully customizable to meet your unique research or production needs, ensuring you achieve maximum densification while preserving critical nano-structures.

Ready to elevate your material science? Contact KINTEK experts today to find the perfect thermal solution for your lab.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the core processing value of a vacuum hot pressing sintering furnace? Master AZ31 Magnesium Alloy Density

- What is the core function of a vacuum hot press furnace? Achieve Near-Perfect Densification for Nano-Copper

- What are the technical advantages of using an SPS sintering furnace? Elevate Al2O3-TiC Material Performance

- What is hot pressing and how does it work? Achieve Superior Material Density and Strength

- How does the furnace cooling method protect CoCrFeNi(Cu) coatings after vacuum hot pressing sintering? Prevent Cracking & Oxidation for Superior Performance

- What are the common applications of vacuum hot pressing? Essential for High-Performance Materials

- How does multi-station continuous vacuum hot pressing sintering equipment affect the production efficiency of diamond products? Boost Yields with Pipeline Sintering

- What is the role of HIP equipment in the diffusion bonding of 6061 aluminum alloy? Achieve High-Integrity Metallurgy