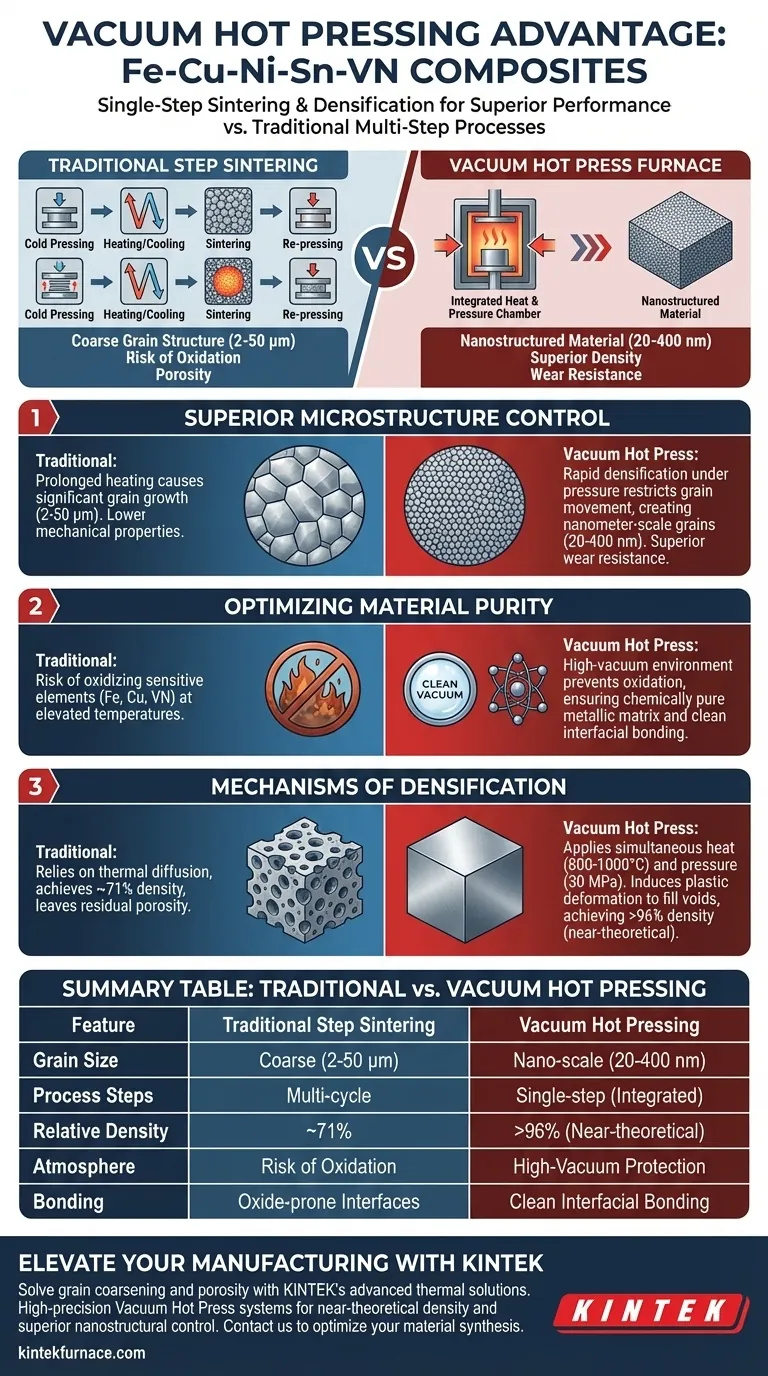

The definitive advantage of a vacuum hot press furnace lies in its ability to integrate sintering and densification into a single, high-efficiency step. By eliminating the separate heating and cooling cycles inherent in traditional step sintering, this process prevents the grain coarsening that typically compromises the mechanical integrity of Fe-Cu-Ni-Sn-VN composites.

Core Takeaway Vacuum hot pressing fundamentally changes the microstructure of composites by applying heat and pressure simultaneously. This creates nanostructured materials with superior density and wear resistance, avoiding the coarse grains and porosity issues common in traditional multi-step manufacturing.

Superior Microstructure Control

Drastic Reduction in Grain Size

Traditional processing methods—involving cold pressing followed by sintering and re-pressing—expose materials to prolonged heating. This thermal history causes grains to grow significantly, often reaching sizes of 2-50 microns.

In contrast, the vacuum hot press furnace suppresses this excessive growth. By densifying the material rapidly under pressure, it restricts grain movement, resulting in significantly finer grain sizes ranging from 20 to 400 nm.

Enhanced Mechanical Performance

The correlation between grain size and performance is direct. The nanostructure achieved through vacuum hot pressing yields a material with superior wear resistance.

Conversely, the coarser grains produced by traditional methods result in lower mechanical properties. The vacuum hot press process ensures the final composite is harder and more durable.

Optimizing Material Purity

Prevention of Oxidation

Fe-Cu-Ni-Sn-VN composites contain elements like iron, copper, and vanadium nitride that are highly sensitive to oxygen at elevated temperatures. A standard sintering environment poses a risk of oxidizing these metal powders.

The vacuum hot press furnace operates in a high-vacuum state (e.g., removing gas from powder interstices). This effectively prevents oxidation, ensuring that the metallic matrix and reinforcement particles remain chemically pure.

Clean Interfacial Bonding

Mechanical strength relies heavily on the bond between the different elements in the composite. By removing oxygen, the furnace ensures the cleanliness of material interfaces.

This clean environment promotes effective atomic diffusion and solid solution formation. The result is a stronger, cohesive bond between the matrix and the reinforcement phases, rather than a material weakened by oxide layers.

Mechanisms of Densification

Simultaneous Heat and Pressure

Unlike standard sintering, which relies primarily on thermal diffusion to close pores, vacuum hot pressing applies mechanical pressure (e.g., 30 MPa) alongside high temperatures (800-1000°C).

This combination induces plastic deformation and diffusion creep. The particles are physically forced to rearrange and fill voids while in a thermoplastic state.

Achieving Near-Theoretical Density

Traditional vacuum sintering often leaves residual porosity, sometimes achieving densities of only around 71%. The added axial pressure in a hot press furnace forcibly excludes internal pores.

This capability allows the process to achieve significantly higher densities, often approaching a fully dense state (over 96%). This reduction in porosity is critical for achieving a high hardness and low elastic modulus.

Critical Process Controls

The Necessity of Atmosphere Control

While the vacuum hot press offers superior results, it relies entirely on the integrity of the vacuum environment. Any failure to maintain the vacuum will lead to the very oxidation and interface embrittlement the process is designed to prevent.

Managing Thermal History

The success of this method depends on precise control of the temperature-pressure window. The process must balance high heat for plasticity with sufficient pressure for densification, without crossing thermal thresholds that would trigger rapid grain growth despite the applied pressure.

Making the Right Choice for Your Goal

When selecting a fabrication method for Fe-Cu-Ni-Sn-VN composites, consider your specific performance requirements:

- If your primary focus is Wear Resistance: Choose the vacuum hot press to achieve the nanometer-scale grain sizes (20-400 nm) required for maximum surface durability.

- If your primary focus is Material Purity: Rely on the high-vacuum capabilities of this furnace to prevent oxidation of sensitive elements like copper and vanadium nitride.

- If your primary focus is High Density: Utilize the simultaneous application of 30 MPa pressure to eliminate porosity and achieve >96% density, which standard sintering cannot match.

Vacuum hot pressing transforms the fabrication of complex composites from a multi-step struggle against defects into a precise, single-step engineering solution.

Summary Table:

| Feature | Traditional Step Sintering | Vacuum Hot Pressing |

|---|---|---|

| Grain Size | Coarse (2-50 μm) | Nano-scale (20-400 nm) |

| Process Steps | Multi-cycle (Pressing + Sintering) | Single-step (Integrated) |

| Relative Density | ~71% | >96% (Near-theoretical) |

| Atmosphere | Risk of Oxidation | High-Vacuum Protection |

| Bonding | Oxide-prone Interfaces | Clean Interfacial Bonding |

Elevate Your Composite Manufacturing with KINTEK

Are you struggling with grain coarsening or residual porosity in your material synthesis? KINTEK provides industry-leading thermal solutions designed to solve these exact challenges. Backed by expert R&D and manufacturing, we offer high-precision Vacuum Hot Press systems, Muffle, Tube, Rotary, and CVD furnaces that are fully customizable to your research or production needs.

Our advanced vacuum technology ensures near-theoretical density and superior nanostructural control for sensitive materials like Fe-Cu-Ni-Sn-VN. Don't compromise on material purity—contact us today to find the perfect high-temp furnace for your laboratory.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- What are the disadvantages of hot pressing compared to cold compacting and sintering? Higher Costs and Lower Production Rates

- What are the key components of a vacuum press system? Essential Parts for Uniform Pressure and Precision

- Why is a Vacuum Hot Pressing Sintering Furnace Essential for 6061-20IQC? Unlock High-Performance Composites

- What is the purpose of performing high-temperature degassing in a vacuum furnace before the hot pressing of Al-Cu alloy powders? Ensure Maximum Density and Strength

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- What role do graphite molds play in the vacuum hot press sintering process of IZO targets? Ensuring Purity and Density

- What is the use of a hot press? Achieve Perfect Bonding & High-Performance Materials