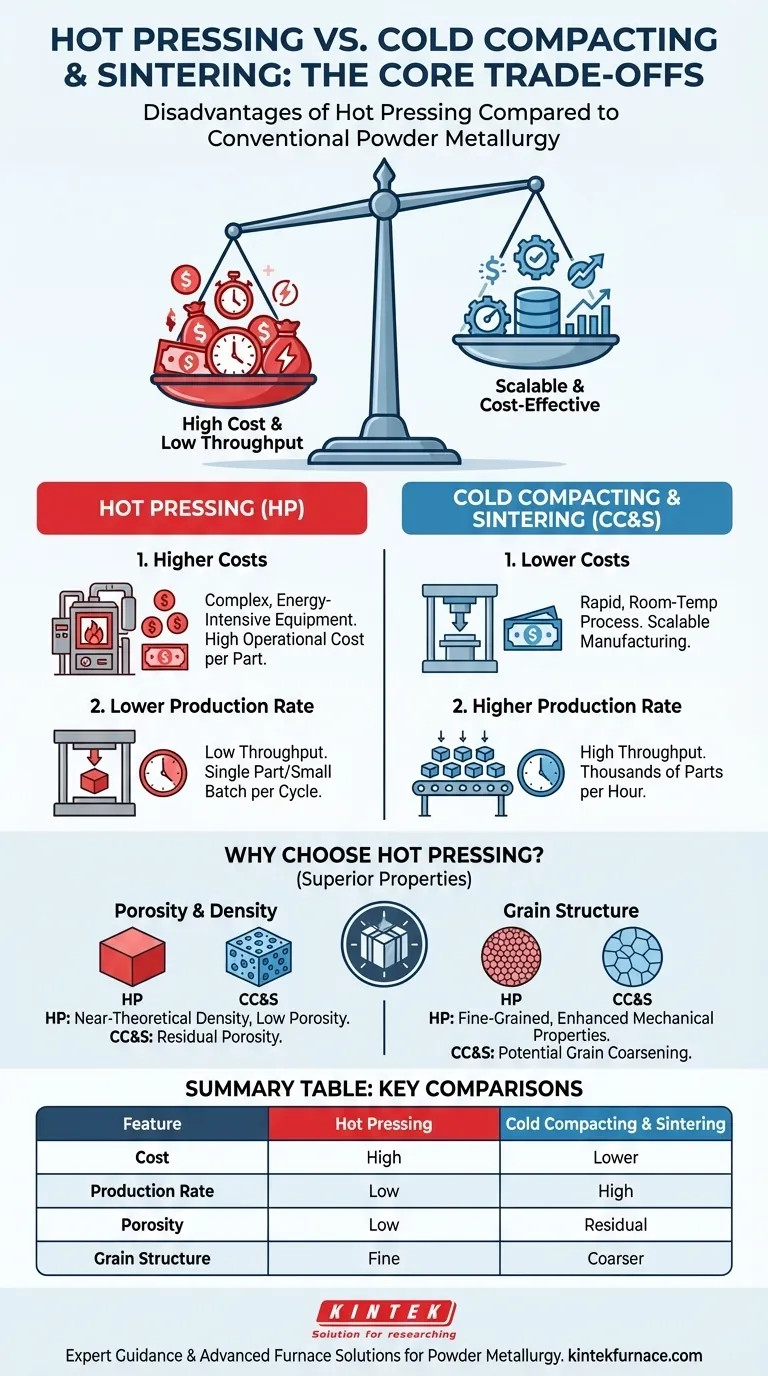

At its core, the primary disadvantages of hot pressing compared to conventional cold compacting and sintering are significantly higher costs and lower production rates. While hot pressing produces superior materials, it is a more complex and energy-intensive process, making it less suitable for high-volume, cost-sensitive applications.

The choice between these two powder metallurgy techniques is not about which is universally "better," but about a fundamental trade-off. Hot pressing prioritizes final material quality and density at the expense of cost and speed, while cold compacting and sintering prioritizes scalability and cost-effectiveness.

The Core Disadvantages: Cost and Productivity

The two most significant drawbacks of adopting a hot pressing process flow are its financial investment and its limited throughput. These factors often make it a non-starter for mass production.

Higher Equipment and Energy Costs

The machinery required for hot pressing is inherently more complex. It must safely handle extreme temperatures and high pressures simultaneously, demanding robust engineering and expensive materials.

This dual-action process is also very energy-intensive. Heating the die and powder for every single cycle consumes a substantial amount of power, driving up the operational cost per part.

Lower Production Throughput

Productivity is a critical limitation. A hot press typically processes only one component or a very small batch at a time within a self-contained heating and pressing cycle.

In contrast, cold compacting is a rapid, room-temperature stamping process that can produce thousands of "green" parts per hour. These parts can then be sintered in large batches in a separate furnace, creating a highly scalable manufacturing line.

Understanding the Trade-offs: Why Choose Hot Pressing?

Despite its disadvantages, hot pressing is used for a reason: it achieves material properties that are often impossible with cold compacting and sintering alone.

The Impact on Porosity and Density

The simultaneous application of heat and pressure in hot pressing effectively eliminates voids between powder particles. This results in components with near-theoretical density and extremely low porosity.

Cold compacting and sintering, on the other hand, often leaves residual porosity in the final part. This can compromise mechanical strength, durability, and resistance to fatigue.

The Control of Grain Structure

Hot pressing promotes a very fine-grained microstructure. The pressure applied during heating physically inhibits grain growth, which is crucial for enhancing mechanical properties like hardness and toughness.

The high temperatures used in conventional sintering (without pressure) can cause grains to coarsen, which may reduce the overall mechanical performance of the final product.

The Time Paradox Explained

While the overall hot pressing process has low throughput, the actual densification phase is remarkably fast—often taking only 3 to 10 minutes.

Conventional sintering, by contrast, can require 1 to 2 hours in a furnace to achieve full densification. The key difference is batch size; you can sinter thousands of cold-compacted parts in that two-hour window, while the hot press produces only one.

Making the Right Choice for Your Application

Selecting the correct process requires a clear understanding of your project's primary objective.

- If your primary focus is mass production and cost-efficiency: Choose cold compacting and sintering for its unparalleled scalability and lower cost per part.

- If your primary focus is maximum performance and density: Choose hot pressing when producing critical components where mechanical failure is not an option.

- If your primary focus is advanced materials: Hot pressing is often the only viable method for fully densifying ceramics or exotic alloys that do not sinter well conventionally.

Ultimately, your decision hinges on balancing the engineering requirements of the component with the economic realities of its production.

Summary Table:

| Disadvantage | Hot Pressing | Cold Compacting and Sizing |

|---|---|---|

| Cost | High equipment and energy costs | Lower cost per part |

| Production Rate | Low throughput, batch processing | High throughput, scalable |

| Porosity | Near-theoretical density, low porosity | Residual porosity may remain |

| Grain Structure | Fine-grained, enhanced properties | Potential grain coarsening |

Need expert guidance on selecting the right high-temperature furnace for your powder metallurgy process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements, whether for high-performance hot pressing or scalable sintering. Contact us today to optimize your lab's efficiency and achieve superior material outcomes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials