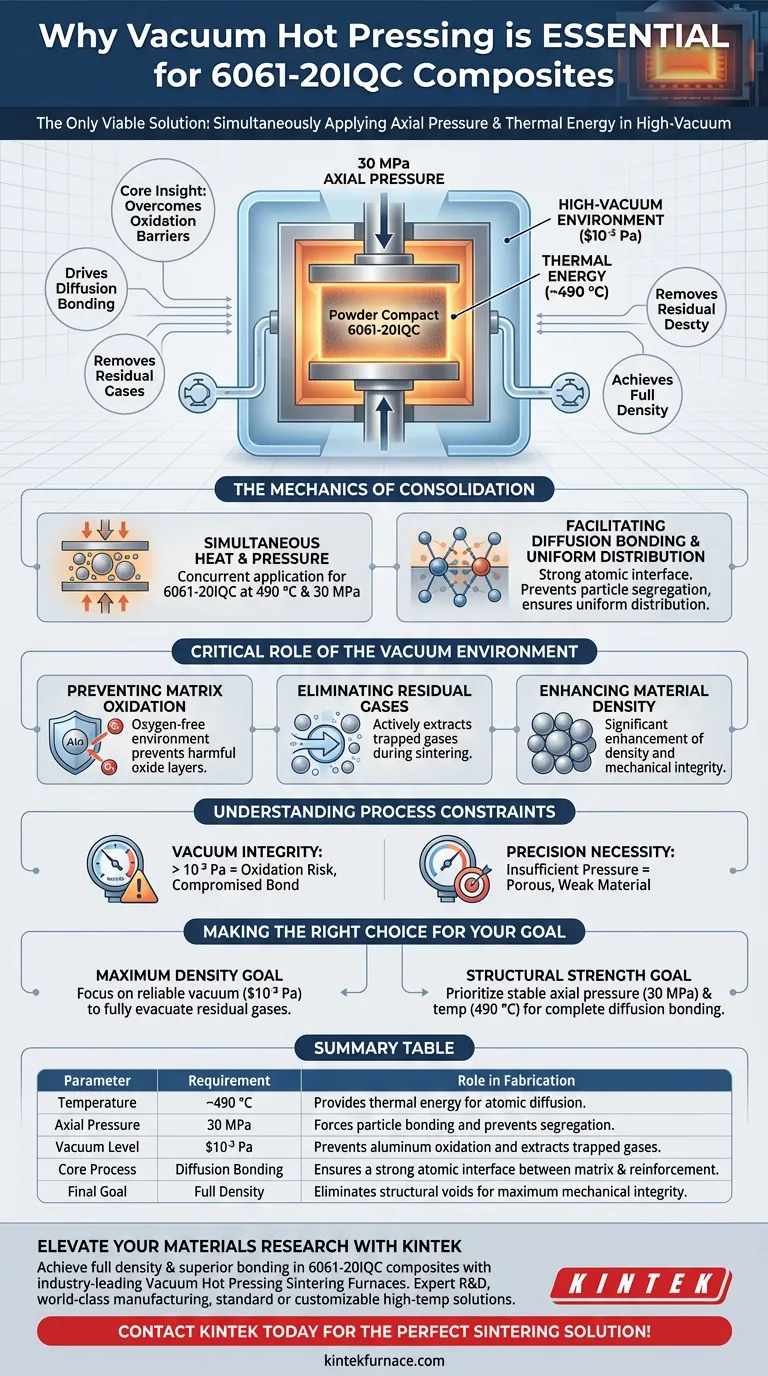

A Vacuum Hot Pressing Sintering Furnace is the only viable solution for fabricating 6061-20IQC composites because it simultaneously applies significant axial pressure and thermal energy within a high-vacuum environment. This specific triad of conditions is required to overcome the natural oxidation barriers of the aluminum matrix and achieve full material density.

The Core Insight Fabricating high-quality aluminum composites requires more than just heat; it demands a controlled environment that actively forces particle bonding while stripping away impurities. Vacuum hot pressing is essential because it drives diffusion bonding at the atomic level while simultaneously removing the residual gases that otherwise create structural voids.

The Mechanics of Consolidation

Simultaneous Heat and Pressure

The primary function of this furnace is the concurrent application of heat and force. For 6061-20IQC materials, this typically involves maintaining a temperature around 490 °C while exerting an axial pressure of 30 MPa.

Facilitating Diffusion Bonding

This specific combination of energy and physical force promotes diffusion bonding. This process ensures a strong atomic interface between the quasicrystal reinforcement and the aluminum matrix powder.

Ensuring Uniform Distribution

The simultaneous application of pressure prevents the segregation of particles. This results in a composite where the reinforcement phase is uniformly distributed throughout the matrix, rather than clumped in specific areas.

The Critical Role of the Vacuum Environment

Preventing Matrix Oxidation

Aluminum is highly reactive to oxygen, which can weaken the final composite. The furnace operates at a high vacuum, typically $10^{-3}$ Pa, to create an oxygen-free environment that prevents the aluminum matrix from oxidizing during the heating phase.

Eliminating Residual Gases

During the sintering process, gases can become trapped between powder particles. The vacuum atmosphere actively extracts these residual gases.

Enhancing Material Density

By removing trapped gases and preventing oxide layers, the vacuum allows the powder particles to pack together more tightly. This significantly enhances the final density and mechanical integrity of the composite material.

Understanding the Process Constraints

Dependence on Vacuum Integrity

The quality of the final material is inextricably linked to the quality of the vacuum. If the pressure rises above the $10^{-3}$ Pa threshold, the risk of matrix oxidation increases immediately, potentially compromising the bond strength.

The Necessity of Precision

This is not a passive process; it requires precise control over the 30 MPa pressure limit. Insufficient pressure will fail to achieve the required diffusion bonding, resulting in a porous, weak material.

Making the Right Choice for Your Goal

To achieve the best results with 6061-20IQC composites, you must tailor the furnace parameters to your specific material targets.

- If your primary focus is Maximum Density: Ensure your vacuum system can reliably maintain $10^{-3}$ Pa to fully evacuate residual gases between particles.

- If your primary focus is Structural Strength: Prioritize maintaining stable axial pressure (30 MPa) at 490 °C to guarantee complete diffusion bonding between the matrix and reinforcement.

Success in fabricating this composite relies on the equipment's ability to maintain a pristine vacuum while delivering substantial force.

Summary Table:

| Parameter | Requirement | Role in Fabrication |

|---|---|---|

| Temperature | ~490 °C | Provides thermal energy for atomic diffusion. |

| Axial Pressure | 30 MPa | Forces particle bonding and prevents segregation. |

| Vacuum Level | $10^{-3}$ Pa | Prevents aluminum oxidation and extracts trapped gases. |

| Core Process | Diffusion Bonding | Ensures a strong atomic interface between matrix and reinforcement. |

| Final Goal | Full Density | Eliminates structural voids for maximum mechanical integrity. |

Elevate Your Materials Research with KINTEK

Achieving full density and superior bonding in advanced composites like 6061-20IQC requires precision engineering. KINTEK provides industry-leading Vacuum Hot Pressing Sintering Furnaces designed to deliver the exact triad of high vacuum, stable thermal energy, and precise axial pressure your project demands.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need a standard lab furnace or a fully customizable high-temperature solution tailored to your unique specifications, our team is ready to support your innovation.

Don't compromise on material integrity—Contact KINTEK today to find the perfect sintering solution for your lab!

Visual Guide

References

- Juan Wang, Zhong Yang. Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging. DOI: 10.3390/coatings14030372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the technical advantages of using a Spark Plasma Sintering (SPS) system for Barium Titanate ceramics?

- What is the vacuum hot pressing technique? Achieve Maximum Density & Purity for Advanced Materials

- What role do vacuum presses play in plastic forming and lamination? Essential Guide for Precision Fabrication

- How does a vacuum hot press furnace contribute to the fabrication of ZnS infrared ceramics? Optimize Optical Quality

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production

- What is activated hot sintering and its advantages? Achieve Superior Material Densification Efficiently

- What core role does a vacuum hot press furnace play in Fe-Cu-Ni-Sn-VN? Mastering Nanostructured Composite Production