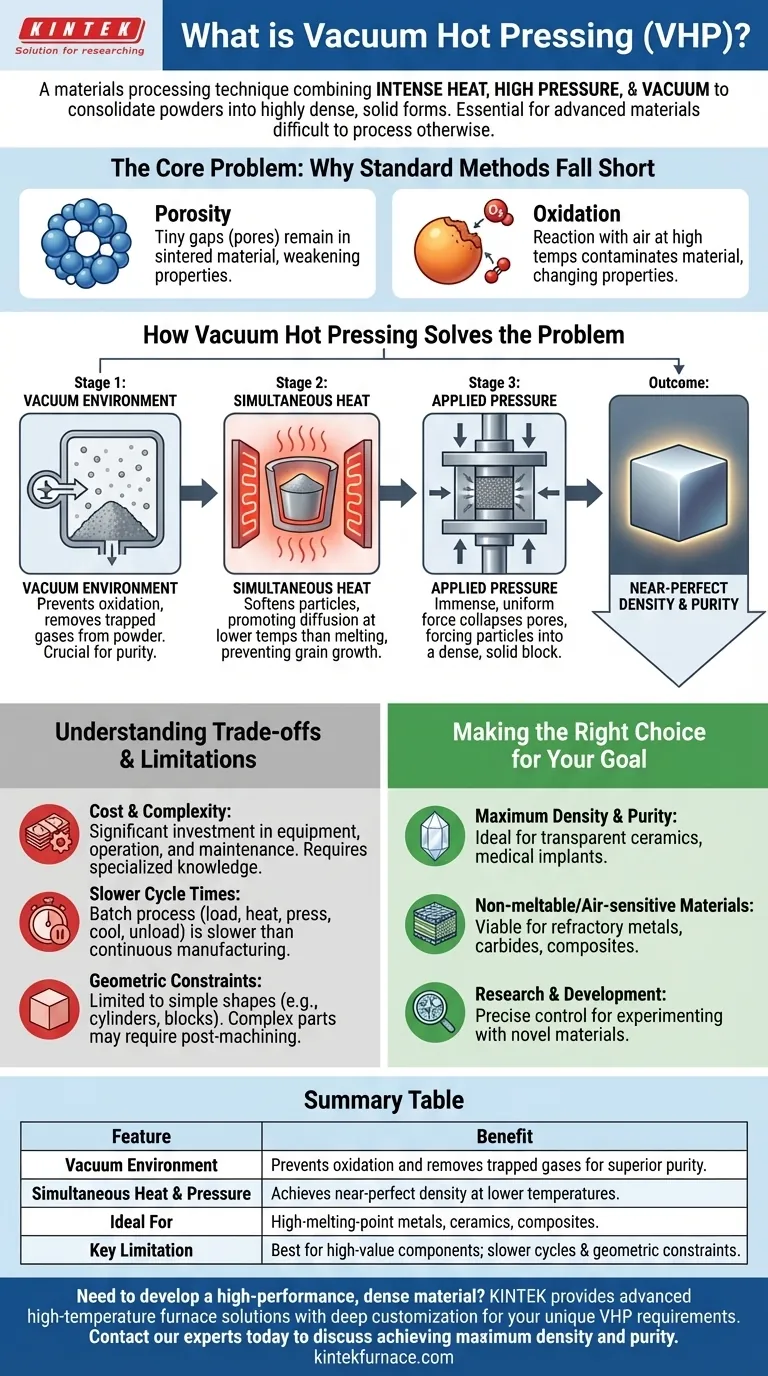

At its core, vacuum hot pressing (VHP) is a materials processing technique that combines three elements—intense heat, high pressure, and a vacuum environment—to consolidate powders into a highly dense, solid form. This process is essential for creating advanced metal, ceramic, and composite materials that cannot be effectively manufactured using traditional melting or sintering methods due to their high melting points or sensitivity to air.

The central purpose of vacuum hot pressing is not just to form a material, but to achieve near-perfect density and purity. It solves the critical challenge of eliminating porosity and preventing oxidation in materials that are otherwise difficult or impossible to densify.

The Core Problem: Why Standard Methods Fall Short

Many advanced materials have extremely high melting points or react aggressively with oxygen at high temperatures. Traditional methods like casting (melting) or atmospheric sintering (heating without pressure) often fail with these materials.

The Challenge of Porosity

When you heat a powder to fuse it together (sintering), tiny gaps or pores can remain trapped within the final material. These pores are weak points that degrade mechanical strength and other critical properties.

The Challenge of Oxidation

Heating reactive materials in the presence of air causes oxidation, which contaminates the material and fundamentally changes its properties. This is a non-starter for high-purity applications in aerospace, electronics, or medicine.

How Vacuum Hot Pressing Solves the Problem

VHP systematically overcomes these challenges by precisely controlling the manufacturing environment. The process can be broken down into three simultaneous actions: heating, pressurization, and maintaining a vacuum.

The Role of High Vacuum

The process begins by placing the raw material (usually a powder) inside a graphite die and placing it in a sealed chamber. The air is then evacuated.

This vacuum environment is critical for two reasons. First, it prevents oxidation and other chemical reactions by removing air. Second, it helps remove trapped gases that are released from the powder as it heats, preventing them from creating new pores.

The Role of Simultaneous Heat

A heating system, often using resistance or induction methods, raises the material's temperature. This softens the powder particles, making them more pliable and promoting atomic diffusion between them.

Crucially, because pressure is also being applied, the required temperature is often lower than the material's melting point or the temperature needed for conventional sintering. This helps prevent unwanted grain growth, which is vital for maintaining the strength of nanomaterials.

The Role of Applied Pressure

While the material is hot and under vacuum, a hydraulic or mechanical press applies immense, uniform pressure. This force physically squeezes the softened particles together, collapsing the pores and forcing the material into a dense, solid block.

The combination of heat and pressure accelerates the densification process far beyond what heat alone could achieve.

Understanding the Trade-offs and Limitations

While powerful, vacuum hot pressing is not a universal solution. Its precision comes with clear trade-offs that make it suitable for specific, high-value applications.

Cost and Complexity

VHP equipment is expensive to acquire, operate, and maintain. The systems require specialized knowledge for operation and programming, representing a significant investment compared to standard furnaces.

Slower Cycle Times

VHP is a batch process, not a continuous one. Each cycle involves loading, evacuating the chamber, heating, pressing, cooling, and unloading. This makes it inherently slower and less suited for high-volume, low-cost manufacturing.

Geometric Constraints

The final part's shape is constrained by the geometry of the die (typically simple shapes like cylinders or blocks). Complex, near-net-shape manufacturing is often not feasible, and post-process machining may be required.

Making the Right Choice for Your Goal

VHP is a specialized tool for specific challenges. Its use is dictated by the material's properties and the desired outcome for the final component.

- If your primary focus is maximum density and purity: VHP is the gold standard for producing components like transparent ceramics or medical-grade implants where zero porosity and no contamination are required.

- If you are processing non-meltable or air-sensitive materials: VHP is one of the few viable methods for consolidating materials like refractory metals, certain carbides, or advanced ceramic composites.

- If you are conducting research and development: The precise control offered by VHP makes it an invaluable tool for experimenting with novel materials, including metal powders, composites, and nanostructured materials.

Ultimately, choosing vacuum hot pressing means prioritizing final material quality and performance above all other manufacturing considerations.

Summary Table:

| Feature | Benefit |

|---|---|

| Vacuum Environment | Prevents oxidation and removes trapped gases for superior purity. |

| Simultaneous Heat & Pressure | Achieves near-perfect density at lower temperatures than conventional sintering. |

| Ideal For | High-melting-point metals, ceramics, composites, and sensitive materials. |

| Key Limitation | Best for high-value components; slower cycle times and geometric constraints vs. mass production. |

Need to develop a high-performance, dense material?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet unique experimental requirements like vacuum hot pressing.

Contact our experts today to discuss how we can help you achieve maximum density and purity for your advanced material project.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the primary advantages of FAST/SPS in Ti-6Al-4V recycling? Transform Efficiency with Solid-State Sintering

- What are the advantages of using a vacuum hot press sintering furnace for preparing high-density carbon nanotube reinforced copper matrix composites? Achieve Maximum Density and Purity for Superior Performance

- What are the key applications of vacuum pressing in composite material processing? Enhance Material Quality and Shape Complexity

- What are the technical advantages of a Spark Plasma Sintering (SPS) system? Achieve Superior TiB2 Ceramic Performance

- Why is 'final short-time pressing' important in vacuum hot pressing? Unlock Maximum Material Density

- Why is high-precision temperature control critical in SiC/Al sintering? Prevent Brittle Phases and Enhance Strength

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength

- How does the heating mechanism of Spark Plasma Sintering (SPS) function? Enhance TiC/SiC Composite Fabrication