The primary advantages of hot pressing are its ability to produce components with exceptionally high density, superior mechanical strength, and precise dimensional control. By simultaneously applying high temperature and mechanical pressure in a controlled atmosphere, the process accelerates material consolidation, resulting in finished parts with minimal porosity and complex shapes that are difficult to achieve with other methods.

While many processes can create dense parts, they often do so at the cost of dimensional accuracy or require high temperatures that degrade material properties. Hot pressing uniquely overcomes this by using pressure to achieve full densification at lower temperatures, preserving fine microstructures and delivering near-net-shape components with superior integrity.

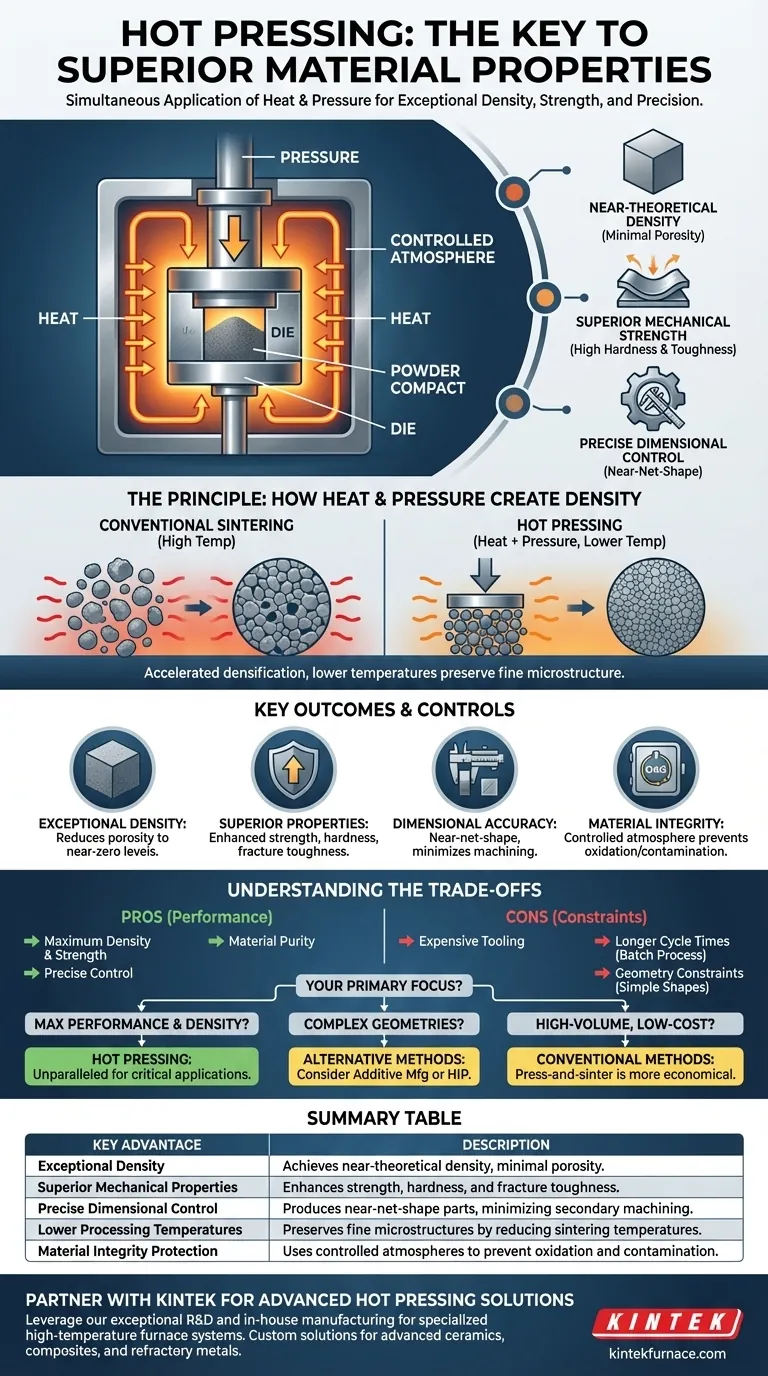

The Principle: How Heat and Pressure Create Density

Hot pressing is not simply heating and squeezing. It is a sophisticated technique that manipulates material physics at the microstructural level to achieve results that are otherwise unattainable.

Accelerating Densification

The applied pressure forces material particles into intimate contact, closing the gaps and pores between them. This dramatically enhances the diffusion process, which is the mechanism by which atoms move to form solid bonds and eliminate voids. The result is a billet with a density that approaches the material's theoretical maximum.

Lowering Sintering Temperatures

In conventional sintering (heating without pressure), very high temperatures are needed to drive the diffusion required for densification. These high temperatures can cause unwanted grain growth, which often weakens the final material. Hot pressing allows for full density to be reached at significantly lower temperatures, preserving a fine-grained microstructure that is critical for high strength and toughness.

Facilitating Material Transformations

The combination of heat and pressure in a controlled environment can be used to induce specific phase transformations or solid-state reactions within a material. This allows for the creation of composites or alloys with engineered properties, such as enhanced thermal stability or hardness, directly during the forming process.

Key Outcomes and Manufacturing Controls

The underlying principles of hot pressing translate directly into tangible manufacturing advantages that are critical for high-performance applications.

Outcome: Near-Theoretical Density

The most significant benefit is the reduction of porosity to near-zero levels. This void-free structure is the foundation for almost all other property improvements, as pores are natural stress concentrators and points of failure.

Outcome: Superior Mechanical Properties

Because the material is highly dense and possesses a fine-grained microstructure, hot-pressed parts exhibit exceptional mechanical strength, hardness, and fracture toughness. They are less prone to cracking and can withstand higher loads than parts made by conventional powder metallurgy.

Control: Exceptional Dimensional Accuracy

The material is consolidated within a rigid die. This ensures that the final component conforms precisely to the desired shape and dimensions, producing a near-net-shape part. This minimizes or eliminates the need for expensive and time-consuming secondary machining operations.

Control: Protecting Material Integrity

Hot pressing is typically performed in a vacuum or an inert gas atmosphere (like argon). This prevents oxidation and contamination, which is absolutely essential when working with reactive materials such as titanium, refractory metals, or certain advanced ceramics.

Understanding the Trade-offs

No process is without its limitations. A clear-eyed assessment of the trade-offs is necessary to determine if hot pressing is the correct choice for your goal.

Tooling and Geometry Constraints

The dies used in hot pressing must withstand extreme temperature and pressure, making them expensive to design and fabricate from specialized materials like graphite or ceramic composites. Furthermore, the process is best suited for parts with a consistent cross-section; complex internal cavities or undercuts are extremely difficult or impossible to produce.

Cycle Time and Throughput

Hot pressing is a batch process that involves significant time for heating, pressing, and cooling. Compared to continuous processes or conventional cold pressing, its cycle times are much longer. This makes it less suitable for high-volume, low-cost consumer parts and better suited for high-value, lower-volume components.

Material Compatibility

The workpiece material must be thermally stable at the pressing temperature and must not react chemically with the die material. This requires careful selection of both the powder being pressed and the tooling to prevent adhesion or contamination.

Making the Right Choice for Your Application

Selecting the right manufacturing process requires aligning its capabilities with your primary objective.

- If your primary focus is maximum performance and density: Hot pressing is an unparalleled choice for creating components where low porosity and high mechanical strength are non-negotiable.

- If your primary focus is manufacturing complex internal geometries: You should evaluate alternative methods like additive manufacturing or hot isostatic pressing (HIP), as hot pressing is limited by its reliance on a physical die.

- If your primary focus is high-volume, low-cost production: Simpler processes like conventional press-and-sinter are more economical due to their faster cycle times and lower tooling costs.

By understanding its unique capabilities and inherent trade-offs, you can strategically leverage hot pressing to manufacture materials that meet the most demanding specifications.

Summary Table:

| Key Advantage | Description |

|---|---|

| Exceptional Density | Achieves near-theoretical density with minimal porosity. |

| Superior Mechanical Properties | Enhances strength, hardness, and fracture toughness. |

| Precise Dimensional Control | Produces near-net-shape parts, minimizing secondary machining. |

| Lower Processing Temperatures | Preserves fine microstructures by reducing sintering temperatures. |

| Material Integrity Protection | Uses controlled atmospheres to prevent oxidation and contamination. |

Need to achieve maximum density and superior mechanical properties for your advanced materials?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced high-temperature furnace solutions, including specialized systems for hot pressing. Our product line—featuring Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique material processing requirements.

Whether you are developing advanced ceramics, composites, or refractory metals, our expertise ensures you get the precise thermal and pressure control needed for superior results. Contact us today to discuss how our hot pressing solutions can enhance your R&D and production outcomes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials