In the energy and power generation sector, a Vacuum Hot Press is a critical tool for manufacturing high-performance components that directly improve efficiency and durability. It is used to create dense ceramic parts for solid oxide fuel cells (SOFCs), bond advanced materials for next-generation solar panels, and forge ultra-strong alloys for turbine blades used in power plants. The equipment’s unique ability to create materials with superior integrity is essential for meeting the demands of modern energy systems.

At its core, the contribution of a Vacuum Hot Press is not just making parts, but fundamentally re-engineering the materials they are made from. This process eliminates internal defects, enabling energy components to operate more efficiently and withstand harsher conditions for longer periods.

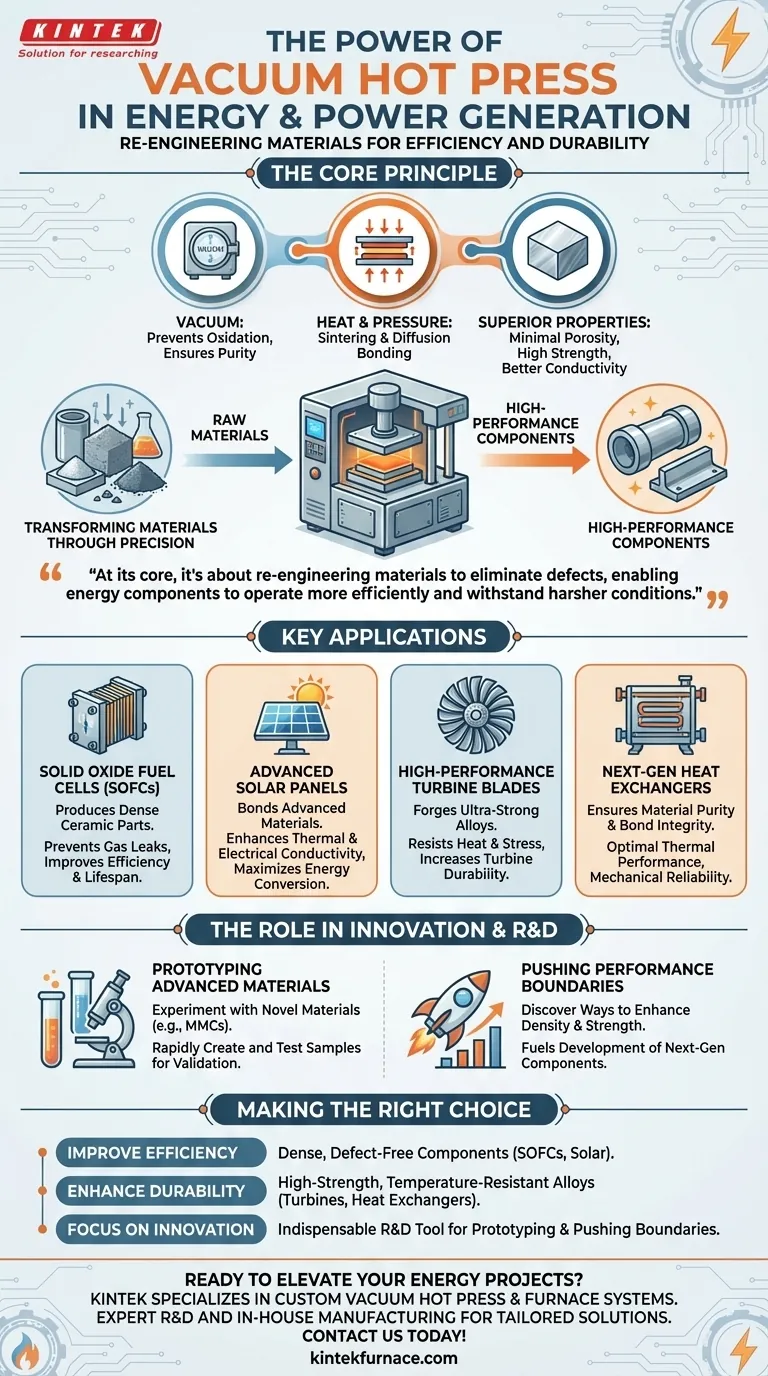

The Core Principle: Why Vacuum, Heat, and Pressure Matter

A Vacuum Hot Press operates by applying immense pressure and high temperatures to materials inside a vacuum chamber. This combination is the key to its transformative capability.

The Role of a Vacuum

Removing air and other gasses from the chamber prevents oxidation and contamination during the heating process. This ensures the chemical purity of the final material, which is critical for components like fuel cells and sensitive electronics.

The Impact of Heat and Pressure

Simultaneously applying heat and uniaxial pressure forces material grains to fuse together. This process, known as sintering or diffusion bonding, dramatically increases the material's density.

The Result: Superior Material Properties

The primary outcome is a component with minimal porosity (fewer internal voids or defects). This lack of defects leads directly to significantly improved mechanical strength, hardness, and thermal conductivity, all of which are vital for demanding energy applications.

Key Applications in Energy and Power Generation

The ability to produce near-perfect materials enables critical advancements across the energy landscape, from clean energy generation to conventional power systems.

Solid Oxide Fuel Cells (SOFCs)

SOFCs generate electricity through an electrochemical reaction and rely on perfectly dense ceramic electrolytes and electrodes. A Vacuum Hot Press produces these ceramic components, ensuring they are free from pores that could leak gas and severely degrade the fuel cell's efficiency and lifespan.

Advanced Solar Panels

For next-generation solar technologies, efficiency is tied to how well different layers of material are bonded. Vacuum Hot Pressing creates powerful, void-free bonds between these layers, improving thermal and electrical conductivity and maximizing the panel's energy conversion rate.

High-Performance Turbine Blades

Turbine blades in gas and steam power plants operate under extreme heat and stress. Using a Vacuum Hot Press, manufacturers can forge high-strength superalloys that resist creep and corrosion, leading to more durable and efficient turbines.

Next-Generation Heat Exchangers

Similar vacuum processing technologies are used to create compact and highly efficient heat exchangers. The integrity of the bonds and the purity of the materials ensure optimal thermal performance and mechanical reliability in systems that manage waste heat or thermal energy storage.

The Role in Research and Development

While a Vacuum Hot Press is used for manufacturing, its most significant impact is often in innovation. It is not typically a tool for high-volume, low-cost production but rather for creating high-value, cutting-edge components.

Prototyping Advanced Materials

R&D labs use this equipment to experiment with novel materials like metal matrix composites (MMCs) and advanced ceramics. It allows them to rapidly create and test small samples to validate new material theories.

Pushing Performance Boundaries

The press is a fundamental research tool for discovering new ways to enhance material density and strength. This research directly fuels the development of next-generation components that will make future energy systems more powerful and reliable.

Making the Right Choice for Your Goal

To understand its value, consider how this technology aligns with specific objectives in the energy sector.

- If your primary focus is improving efficiency: A Vacuum Hot Press enables the creation of dense, defect-free components for SOFCs and solar cells, maximizing their energy output.

- If your primary focus is enhancing durability: This technology is essential for producing high-strength, temperature-resistant alloys for turbine blades and heat exchangers that must survive harsh operating conditions.

- If your primary focus is innovation: The equipment is an indispensable R&D tool for prototyping new materials and pushing the scientific boundaries of material performance.

Ultimately, advancements in energy generation are fundamentally tied to the quality of the materials we use to build them.

Summary Table:

| Application | Key Contribution |

|---|---|

| Solid Oxide Fuel Cells (SOFCs) | Produces dense ceramic parts to prevent gas leaks and improve efficiency |

| Advanced Solar Panels | Bonds layers for better thermal and electrical conductivity, maximizing energy conversion |

| High-Performance Turbine Blades | Forges strong alloys to resist heat and stress, enhancing turbine durability |

| Next-Generation Heat Exchangers | Ensures material purity and bond integrity for optimal thermal performance |

Ready to elevate your energy projects with advanced high-temperature solutions? KINTEK specializes in custom Vacuum Hot Press equipment and other furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our expert R&D and in-house manufacturing ensure tailored solutions for your unique needs—contact us today to discuss how we can boost your efficiency and innovation! Get in touch now

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy