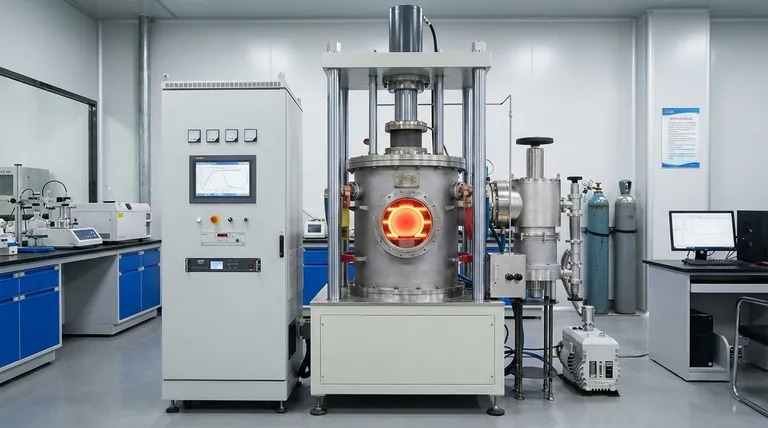

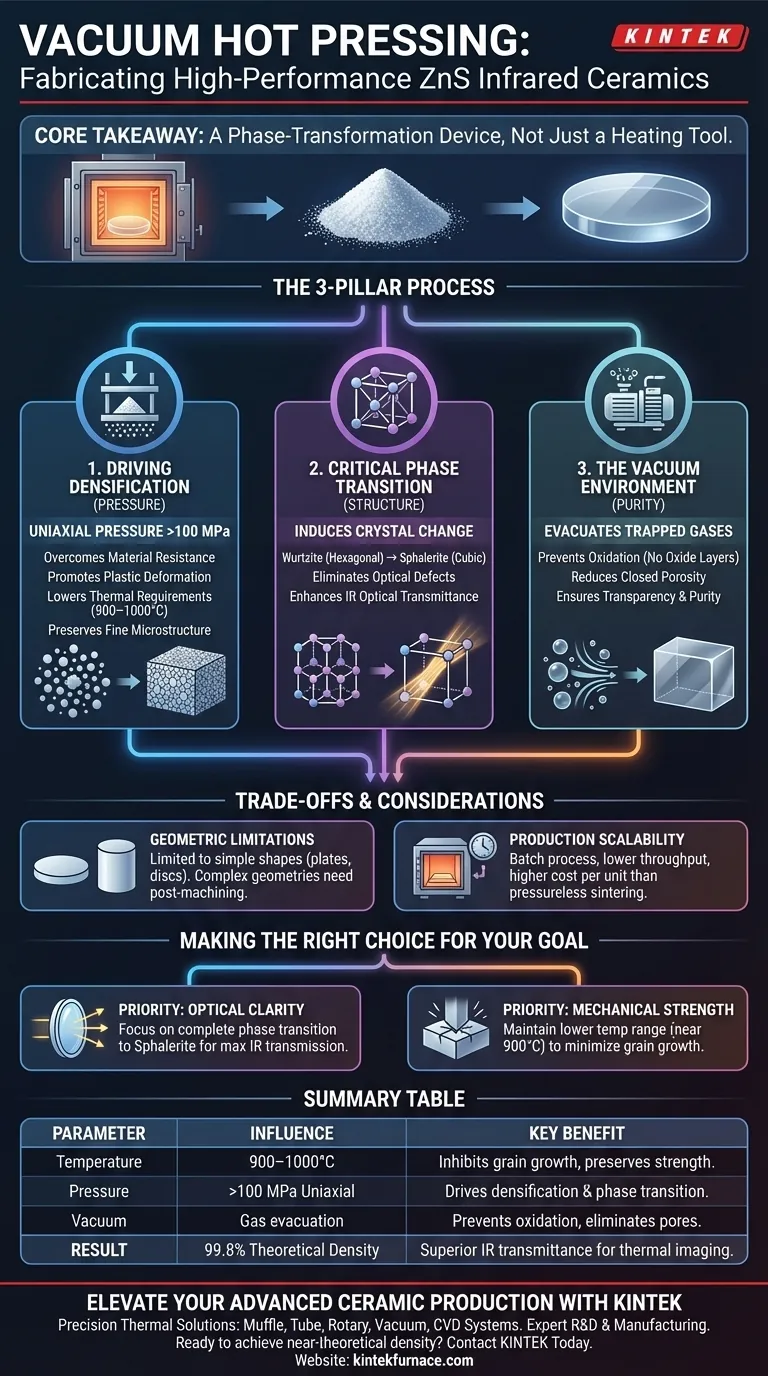

A vacuum hot press furnace acts as the primary densification engine for fabricating Zinc Sulfide (ZnS) infrared ceramics. By applying simultaneous heat (900–1000°C) and high uniaxial mechanical pressure (greater than 100 MPa) within a vacuum, the furnace forces the raw powder to compact into a solid, optically clear material.

Core Takeaway The vacuum hot press is not merely a heating tool; it is a phase-transformation device. It utilizes mechanical pressure to drive densification and induce a critical crystal structure change (wurtzite to sphalerite) at temperatures low enough to prevent grain growth, ensuring the final ceramic combines high mechanical strength with superior infrared transmission.

Driving Densification Through Pressure

Overcoming Material Resistance

ZnS powders naturally resist consolidation. The furnace overcomes this by applying significant uniaxial pressure, which promotes plastic deformation and diffusion creep. This mechanical force physically rearranges particles and closes voids that heat alone cannot eliminate.

Lowering Thermal Requirements

Traditional sintering requires extreme heat to achieve density, which often leads to oversized grains and poor mechanical strength. The added pressure allows ZnS to reach near-theoretical density (e.g., 99.8%) at much lower temperatures (typically 900–1000°C).

Preserving Fine Microstructure

By operating at these lower temperatures, the process inhibits excessive grain growth. This results in a fine-grained microstructure, which is essential for maximizing the mechanical properties and durability of the final ceramic component.

The Critical Phase Transition

Inducing Crystal Structure Changes

For ZnS to function effectively as an infrared window, it must possess a specific crystal structure. The high-pressure environment (often >100 MPa) induces a phase transition from the wurtzite phase to the sphalerite phase.

Eliminating Optical Defects

This transition is not just structural; it is optical. The shift to sphalerite is essential for eliminating residual pores and scattering centers. This directly enhances the material's infrared optical transmittance, making it suitable for high-performance thermal imaging and sensor applications.

The Role of the Vacuum Environment

Evacuating Trapped Gases

The vacuum atmosphere plays a vital role in purity. It evacuates air trapped between powder particles and removes volatile gases generated during the heating process.

Preventing Oxidation

ZnS and potential sintering additives are sensitive to oxygen at high temperatures. The vacuum environment prevents oxidation, which would otherwise form opaque oxide layers (impurities) at the grain boundaries and degrade optical performance.

Reducing Closed Porosity

By removing adsorbed gases before the material seals up, the vacuum minimizes the formation of closed pores inside the ceramic. This reduction in porosity is the final key to achieving a fully dense, transparent sintered body.

Understanding the Trade-offs

Geometric Limitations

Because the pressure is applied uniaxially (from top and bottom), hot pressing is generally limited to simple shapes like flat plates, discs, or cylinders. Complex 3D geometries often require post-process machining, which adds cost.

Production Scalability

Vacuum hot pressing is inherently a batch process. While it produces superior quality materials compared to pressureless sintering, it generally has lower throughput and higher operational costs per unit.

Making the Right Choice for Your Goal

To maximize the potential of ZnS ceramics, align your processing parameters with your specific application requirements:

- If your primary focus is Optical Clarity: Prioritize pressure parameters that ensure a complete phase transition to sphalerite, as this is the dominant factor in infrared transmission.

- If your primary focus is Mechanical Strength: Focus on maintaining the lower end of the temperature range (near 900°C) to minimize grain growth while relying on higher pressure for densification.

The vacuum hot press furnace transforms ZnS from a loose powder into a sophisticated optical component by substituting thermal excess with mechanical force.

Summary Table:

| Parameter | Influence on ZnS Ceramics | Key Benefit |

|---|---|---|

| Temperature | 900–1000°C range | Inhibits grain growth, preserving mechanical strength. |

| Pressure | >100 MPa Uniaxial | Drives densification and wurtzite-to-sphalerite phase transition. |

| Vacuum | Gas evacuation | Prevents oxidation and eliminates internal scattering pores. |

| Result | 99.8% Theoretical Density | Superior IR transmittance for thermal imaging components. |

Elevate Your Advanced Ceramic Production with KINTEK

Precision in vacuum hot pressing is the difference between an opaque material and a high-performance optical component. KINTEK provides industry-leading thermal solutions, including customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, backed by expert R&D and manufacturing.

Whether you are refining ZnS infrared ceramics or developing specialized alloys, our high-temp furnaces are engineered to meet your unique material requirements.

Ready to achieve near-theoretical density and superior optical clarity?

Contact KINTEK Today for a Expert Consultation

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What advantages does a vacuum press offer in material processing? Achieve Superior Density and Purity

- How are hot press furnaces involved in semiconductor manufacturing? Essential for Wafer Bonding in 3D ICs

- Why is high-intensity mechanical pressure control essential in hot press sintering? Achieve Nano-Copper Densification

- What are the main advantages of hot pressing in powder metallurgy? Achieve High-Density, Fine-Grained Components

- What role does a high-strength graphite mold play in hot-press sintering? Optimize Al2O3/TiC/SiC(w) Density

- How does the vacuum environment facilitate the densification of ZnS ceramics? Unlock High-Performance Liquid Sintering

- What is the purpose of vacuum hot pressing? Achieve Superior Material Density and Purity

- What are the key components of a vacuum press system? Essential Parts for Uniform Pressure and Precision