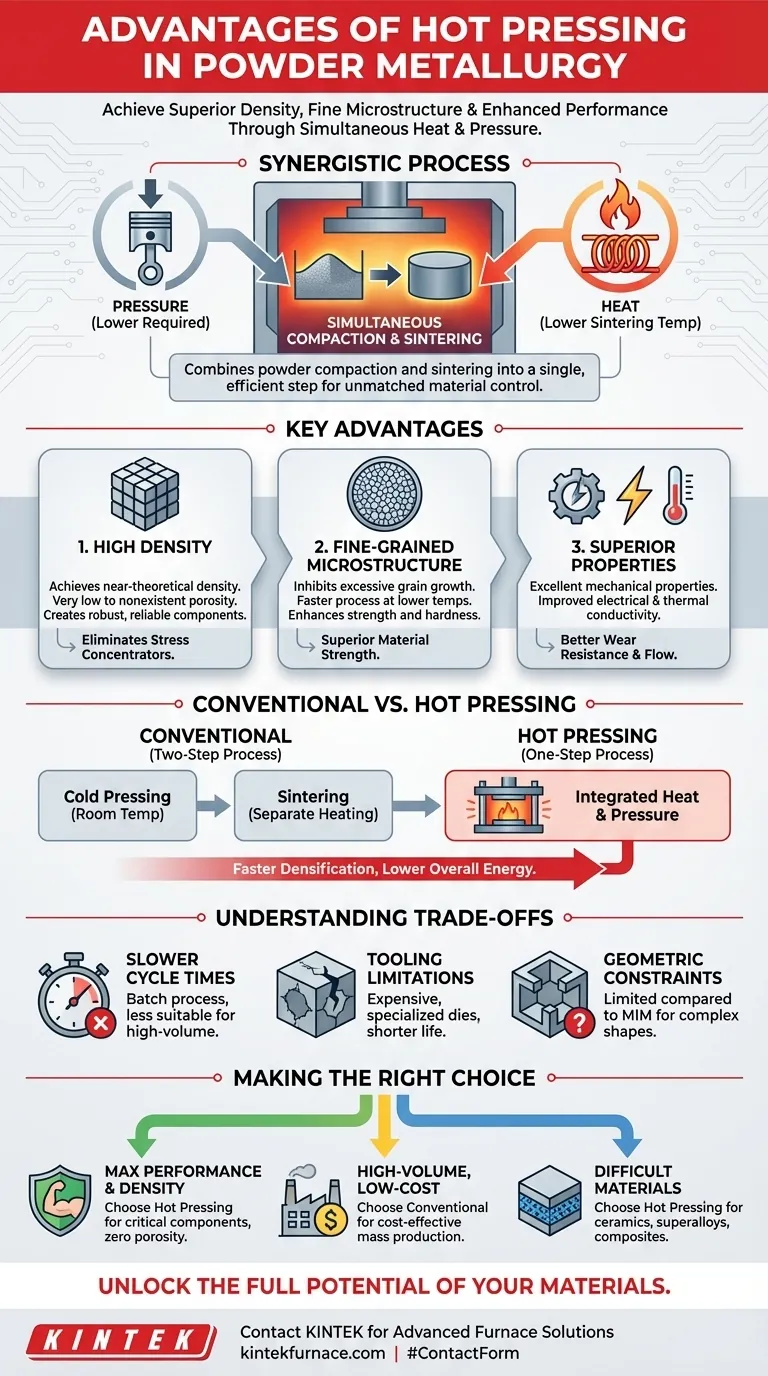

From a technical standpoint, the primary advantages of hot pressing in powder metallurgy are its ability to achieve exceptionally high density and a fine-grained microstructure in the final component. This is accomplished by applying heat and pressure simultaneously, which significantly reduces the pressure required—often to just 10% of that needed for cold pressing—while also lowering the necessary sintering temperature and time.

Hot pressing integrates powder compaction and sintering into a single, synergistic process. This isn't merely an efficiency gain; it's a method for achieving a level of material density and microstructural control that is often impossible with separate pressing and sintering operations.

How Hot Pressing Unlocks Superior Properties

Hot pressing fundamentally changes how powder particles consolidate. By applying thermal energy and mechanical force at the same time, it creates an environment highly conducive to densification.

The Role of Simultaneous Heat and Pressure

In conventional powder metallurgy, parts are first compacted at room temperature (cold pressing) and then heated in a separate step (sintering).

Hot pressing combines these into one step. The elevated temperature makes the powder particles more malleable, a state known as plastic deformation. This softening means the particles deform and conform to each other with far less applied pressure.

Accelerated Densification

The applied heat also dramatically accelerates mass transfer mechanisms like diffusion. Atoms move more readily between particles, filling the voids (porosity) between them much faster and at lower overall temperatures than required for pressureless sintering.

Key Advantages for Material Performance

The unique mechanism of hot pressing directly translates into tangible improvements in the final component's quality and performance.

Achieving Near-Theoretical Density

The most significant advantage of hot pressing is its ability to produce parts with very low to nonexistent porosity, approaching the material's theoretical maximum density.

Porosity acts as a stress concentrator and is a primary point of failure in powder metal parts. By nearly eliminating it, hot pressing creates a much more robust and reliable component.

Refining the Grain Structure

While heat promotes densification, it can also cause undesirable grain growth, which can make a material weaker.

Because hot pressing is faster and occurs at lower temperatures than conventional sintering, it effectively inhibits excessive grain growth. This results in a fine-grained microstructure, which is critical for enhancing a material's strength and hardness.

Superior Mechanical and Electrical Properties

The combination of high density and fine grains directly leads to excellent mechanical properties, including superior strength, toughness, and wear resistance.

For conductive materials, eliminating the voids that would otherwise impede the flow of electrons also results in significantly improved electrical and thermal conductivity.

Understanding the Trade-offs

No process is universally superior. While powerful, hot pressing has specific trade-offs that are critical to consider.

Slower Cycle Times

Hot pressing is generally a slower batch process compared to the continuous, high-volume nature of cold pressing and sintering. Heating and cooling the die and component for each cycle takes time, making it less suitable for mass production of simple parts.

Tooling and Die Limitations

The dies used in hot pressing must withstand extreme temperatures and pressures simultaneously. This requires the use of expensive, specialized materials like graphite or ceramic composites. These dies have a shorter operational life and are more costly to manufacture and replace than cold pressing tooling.

Geometric Constraints

While the references note the ability to make "complex shapes," this is relative. Hot pressing is excellent for producing robust shapes but is generally more limited in geometric complexity than processes like metal injection molding (MIM). Thin walls, sharp internal corners, and extreme aspect ratios can be challenging to execute.

Making the Right Choice for Your Goal

Selecting hot pressing depends entirely on your project's non-negotiable requirements. It is a precision tool for achieving specific, high-performance outcomes.

- If your primary focus is maximum performance and density: Hot pressing is the ideal choice for creating critical components where porosity must be eliminated to achieve top-tier mechanical or electrical properties.

- If your primary focus is high-volume, low-cost production: Conventional cold pressing followed by sintering will likely be more cost-effective due to its faster cycle times and lower tooling costs.

- If your primary focus is processing difficult-to-sinter materials: Hot pressing excels with materials like technical ceramics, superalloys, and composites that resist densification through pressureless sintering alone.

Ultimately, hot pressing empowers you to create advanced materials with properties that push the boundaries of conventional powder metallurgy.

Summary Table:

| Advantage | Description |

|---|---|

| High Density | Achieves near-theoretical density with minimal porosity for stronger parts. |

| Fine Microstructure | Inhibits grain growth, resulting in improved strength and hardness. |

| Lower Pressure & Temperature | Reduces required pressure and sintering temperature, saving energy. |

| Enhanced Properties | Boosts mechanical, electrical, and thermal conductivity in final components. |

| Process Efficiency | Combines compaction and sintering into one step for better control. |

Unlock the Full Potential of Your Materials with KINTEK

Are you striving for superior density and performance in your powder metallurgy projects? KINTEK specializes in advanced high-temperature furnace solutions, including Hot Pressing Furnaces, designed to meet the unique demands of laboratories and research facilities. Our expertise in R&D and in-house manufacturing ensures robust, customizable systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor solutions to your specific experimental needs, helping you achieve precise material properties and efficiency gains.

Don't let process limitations hold you back—contact us today to discuss how our hot pressing technologies can elevate your results and drive innovation in your work!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity