The vacuum environment acts as a chemical trigger that fundamentally alters the sintering mechanism. Within a hot press furnace, the high-temperature vacuum induces the selective volatilization of sulfur ions from the Zinc Sulfide (ZnS) powder. This process leaves behind residual metallic zinc, which melts to form a liquid phase at the grain boundaries, acting as a critical sintering aid to accelerate densification.

The vacuum environment does not merely remove air; it actively modifies the material's stoichiometry to enable liquid phase sintering. By promoting sulfur loss, it generates an intrinsic metallic zinc liquid phase that enhances particle wetting and mass transport, resulting in a high-density ceramic body.

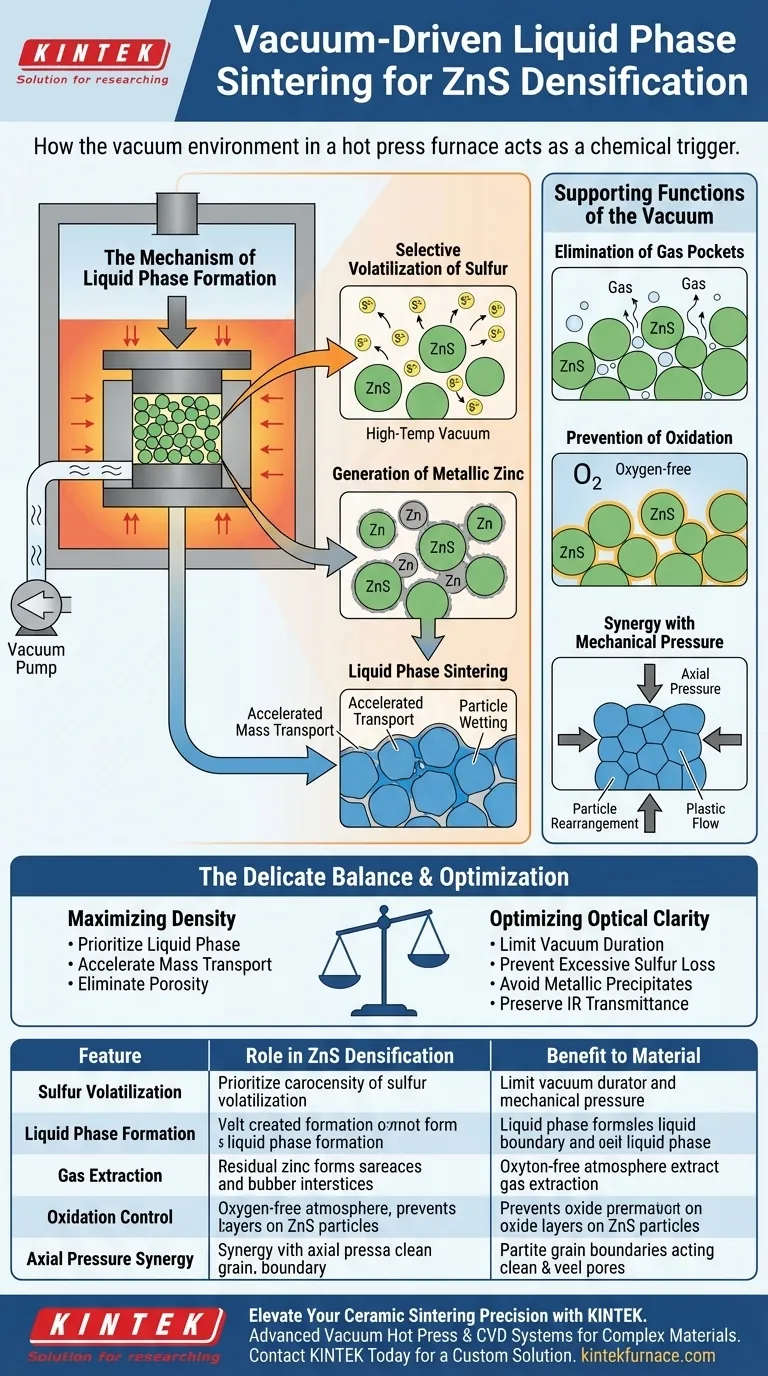

The Mechanism of Liquid Phase Formation

Selective Volatilization of Sulfur

The primary function of the vacuum in this specific context is to drive the chemistry required for liquid phase sintering. Under high temperatures, the vacuum environment lowers the vapor pressure threshold, promoting the escape of sulfur ions from the ZnS lattice.

Generation of Metallic Zinc

As sulfur volatilizes, it disrupts the stoichiometric balance of the ceramic powder. This leaves behind an excess of metallic zinc at the microscopic level.

Liquid Phase Sintering

At the sintering temperatures typically used in hot pressing, this residual metallic zinc melts. This creates a liquid phase at the grain boundaries that wets the solid ZnS particle surfaces. This liquid acts as a fast-track medium for mass transport, allowing atoms to move more freely than they would in a solid state, effectively filling pores and densifying the material.

Supporting Functions of the Vacuum

Elimination of Gas Pockets

Beyond the chemical reaction, the vacuum physically extracts adsorbed gases and volatile impurities trapped within the powder interstices. By removing these gases before the pores close, the vacuum prevents the formation of micro-pores that would otherwise lower the density.

Prevention of Oxidation

High vacuum levels (e.g., $10^{-3}$ Torr) create a protective atmosphere that inhibits the oxidation of the ZnS powder. This is critical because oxide layers can impede diffusion and degrade the optical properties of the final ceramic, such as infrared transmittance.

Synergy with Mechanical Pressure

While the vacuum manages the chemical environment, the "hot press" aspect applies axial mechanical pressure (e.g., 15–30 MPa). The vacuum ensures the grain boundaries are clean and active, allowing the applied pressure to effectively force particle rearrangement and plastic flow without resistance from trapped gases.

Understanding the Trade-offs

The Risk of Non-Stoichiometry

While the loss of sulfur is necessary to create the liquid zinc phase, it presents a delicate balancing act. If the vacuum induces excessive volatilization, the material may become too non-stoichiometric.

Impact on Optical Properties

An excess of metallic zinc can lead to darkening or "fogging" in the final ceramic. This severely impacts the material's ability to transmit light, particularly in the infrared spectrum.

Process Control Sensitivity

Relying on vacuum-induced liquid phase sintering requires precise control over temperature and vacuum levels. Slight deviations can shift the process from helpful densification to detrimental decomposition, making process stability a challenge.

Making the Right Choice for Your Goal

To optimize the densification of ZnS ceramics, you must align your processing parameters with your specific performance metrics.

- If your primary focus is maximum density: Prioritize the vacuum-induced liquid phase mechanism to accelerate mass transport and eliminate porosity through metallic zinc wetting.

- If your primary focus is optical clarity (Infrared Transmittance): Carefully limit the duration and intensity of the vacuum exposure to prevent excessive sulfur loss and the formation of opaque metallic precipitates.

Success depends on utilizing the vacuum not just as a clean environment, but as a precise chemical reagent that activates the sintering process.

Summary Table:

| Feature | Role in ZnS Densification | Benefit to Material |

|---|---|---|

| Sulfur Volatilization | Triggers stoichiometric imbalance | Creates metallic zinc phase |

| Liquid Phase Formation | Wets grain boundaries | Accelerates mass transport |

| Gas Extraction | Removes adsorbed gases | Prevents trapped micro-pores |

| Oxidation Control | Inhibits oxide layer formation | Preserves IR transmittance |

| Axial Pressure Synergy | Facilitates particle rearrangement | Achieves maximum density |

Elevate Your Ceramic Sintering Precision with KINTEK

Achieving the perfect balance between stoichiometry and density requires advanced thermal processing. KINTEK provides world-class Vacuum Hot Press systems and CVD systems, specifically engineered to provide the precise atmospheric control and mechanical pressure needed for complex materials like Zinc Sulfide.

Backed by expert R&D and manufacturing, our customizable lab high-temp furnaces—including Muffle, Tube, Rotary, and Vacuum systems—ensure your research and production meet the highest standards of optical clarity and structural integrity.

Ready to optimize your densification process? Contact KINTEK today for a custom solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role does Hexagonal Boron Nitride (h-BN) coating play in SPS molds? Protect Your Tooling and Purity

- What are the advantages of SPS over hot pressing for high-entropy alloys? Achieve Superior Density and Microstructure

- What are the different pressurization methods used in vacuum hot pressing? Choose Uniaxial vs. HIP for Your Lab

- Why is precise temperature control critical for IZO targets? Master Indium Oxide Volatilization Management

- What core functions do graphite molds serve? Essential Roles in Vacuum Hot Pressing Sintering of SiC/ZTA Ceramics

- What are the mold configuration requirements for sintering non-conductive powders in FAST? Expert Setup Guide

- Why is a Vacuum Hot Press (VHP) furnace preferred over stir casting? Achieve Near-Theoretical Density for Composites

- What is the core function of a vacuum hot press sintering furnace in the consolidation of Cu/rGO composites? Achieve Near-Theoretical Density and Superior Performance