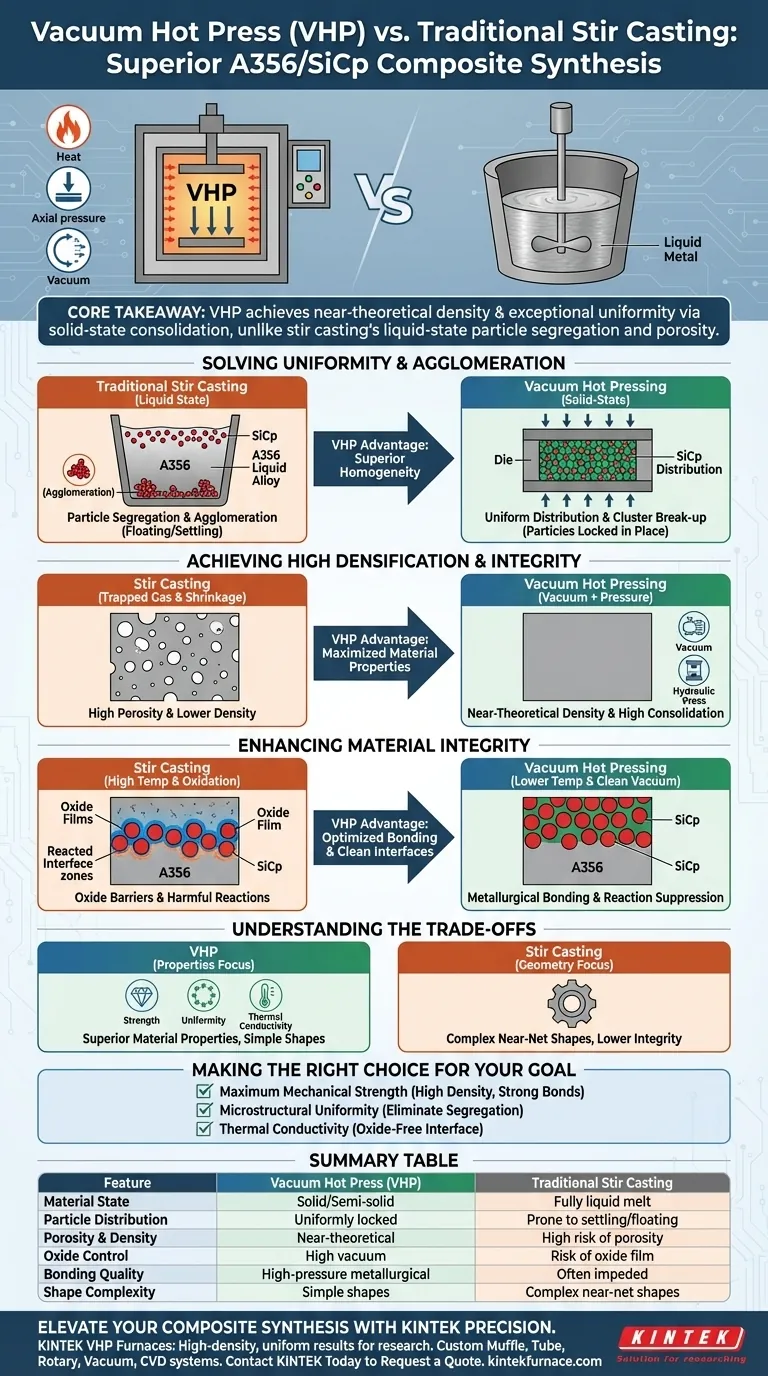

A Vacuum Hot Press (VHP) furnace is the superior choice for high-performance composite synthesis. It is preferred over stir casting primarily because it achieves near-theoretical density and exceptional microstructural uniformity. By applying simultaneous heat, axial pressure, and a vacuum, VHP eliminates common casting defects such as particle agglomeration, floating, and settling.

Core Takeaway While stir casting often results in segregated particles and porosity due to the liquid state of the metal, Vacuum Hot Pressing utilizes solid-state consolidation to lock reinforcing particles in place, ensuring a uniform, dense, and oxidation-free microstructure.

Solving the Uniformity Challenge

Overcoming Particle Segregation

In traditional stir casting, the matrix is fully melted. This liquid state allows SiCp particles to float or settle due to density differences between the ceramic reinforcement and the A356 alloy.

Vacuum Hot Pressing avoids this by using a solid-state or semi-solid process. Because the matrix does not fully melt into a free-flowing liquid, the reinforcing particles are locked in position, ensuring a homogeneous distribution throughout the material.

Eliminating Agglomeration

Fine particles tend to clump together (agglomerate) in liquid melts, creating weak points in the composite.

The VHP process applies significant axial pressure during sintering. This pressure forces the matrix material to flow plastically around the reinforcements, effectively breaking up clusters and preventing the agglomeration that plagues stir casting.

Achieving High Densification

Stir casting is prone to porosity caused by trapped gases or shrinkage during solidification.

VHP produces materials with extremely high density. The combination of vacuum (to remove gas) and high pressure (to close voids) consolidates the material to a level that casting methods simply cannot match.

Enhancing Material Integrity

Breaking the Oxide Barrier

Aluminum alloys like A356 naturally form stubborn oxide films that impede bonding between particles.

The high pressure and temperature in a VHP furnace induce plastic deformation. This deformation physically breaks these oxide films, exposing fresh metal surfaces and inducing true metallurgical bonding between the A356 matrix and the SiCp reinforcement.

Inhibiting Harmful Interfacial Reactions

At the high temperatures required for full melting in stir casting, aluminum can react chemically with silicon carbide, degrading the mechanical properties of the composite.

VHP allows for processing at lower temperatures. This suppresses these harmful chemical reactions, preserving the integrity of both the matrix and the reinforcement.

Preventing Matrix Oxidation

A356 is sensitive to oxidation at high temperatures, which introduces brittle inclusions into the final product.

The high vacuum environment (often <0.1 Pa) of a VHP furnace eliminates oxygen during the heating phase. This ensures clean interfaces and significantly higher thermal conductivity and mechanical strength compared to processing in air or inert gas covers.

Understanding the Trade-offs

Geometry vs. Property Quality

While VHP offers superior material properties, it is a batch process that typically produces simple shapes (discs, cylinders) requiring subsequent machining.

Stir casting can produce complex near-net shapes but sacrifices internal structural integrity. VHP is the trade-off you make when material performance is more critical than geometric complexity or high-volume throughput.

Making the Right Choice for Your Goal

- If your primary focus is Maximum Mechanical Strength: Choose the VHP furnace to ensure high density and strong metallurgical bonding without brittle reaction products.

- If your primary focus is Microstructural Uniformity: Rely on VHP to eliminate particle settling, floating, and agglomeration common in liquid processing.

- If your primary focus is Thermal Conductivity: Use VHP to ensure an oxide-free interface that maximizes heat transfer efficiency.

By leveraging the synergy of vacuum, pressure, and temperature, VHP transforms A356/SiCp from a simple mixture into a high-performance engineering material.

Summary Table:

| Feature | Vacuum Hot Press (VHP) | Traditional Stir Casting |

|---|---|---|

| Material State | Solid-state or semi-solid | Fully liquid melt |

| Particle Distribution | Uniformly locked in position | Prone to settling and floating |

| Porosity & Density | Near-theoretical density | High risk of gas porosity |

| Oxide Control | High vacuum removes oxygen | Risk of oxide film formation |

| Bonding Quality | High-pressure metallurgical bond | Often impeded by interfaces |

| Shape Complexity | Simple shapes (discs/cylinders) | Complex near-net shapes |

Elevate Your Composite Synthesis with KINTEK Precision

Don't let particle agglomeration or oxidation compromise your material integrity. KINTEK provides industry-leading Vacuum Hot Press (VHP) furnaces designed to deliver the high-density and microstructural uniformity your research demands.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. All our lab high-temp furnaces are fully customizable to meet your unique processing needs, ensuring you achieve maximum mechanical strength and thermal conductivity every time.

Ready to optimize your high-performance materials?

Contact KINTEK Today to Request a Quote

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role do vacuum hot press furnaces play in advanced materials development? Forge High-Density, Pure Materials

- Why is a Vacuum Hot Press Sintering (VHPS) furnace preferred for AlxCoCrFeNi high-entropy alloys? Achieve 99% Density

- Can you use a heat press for laminating? A Practical Guide for DIY and Crafting

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What is the core function of a vacuum hot press sintering furnace in the preparation of high-density RuTi alloys? Achieve Maximum Density and Purity

- What role does 30 MPa pressure play in SiC/Cu-Al2O3 sintering? Achieve 97.6% Density with Vacuum Hot Pressing

- What is the impact of grain structure on material properties in hot pressing vs. cold compacting and sintering? Optimize Your Powder Metallurgy Process

- Why is a vacuum hot press furnace required for sintering CNT-Al composites? Optimize Density and Interface Bonding