Yes, you can use a heat press for laminating, provided you use the correct materials and a careful technique. This method works by using the heat press to activate the adhesive in a thermal laminating pouch, creating a seal around your document. While not its intended function, a heat press can serve as a substitute for a dedicated laminator for small, simple jobs.

Using a heat press for lamination is a feasible workaround, but it demands careful control over temperature and pressure. It trades the automated consistency of a dedicated laminator for a manual process that carries a higher risk of error, such as melting or uneven sealing.

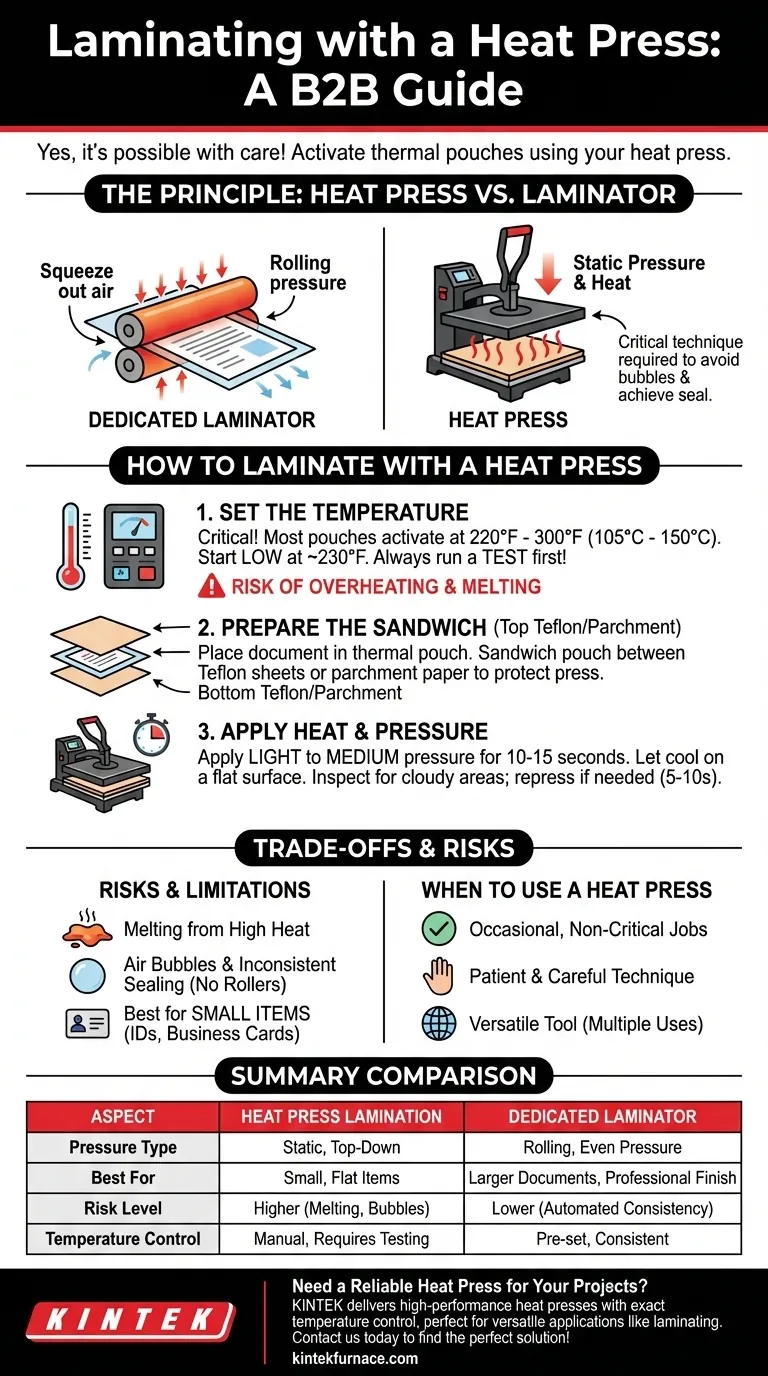

The Principle Behind Thermal Lamination

How a Laminator Works

A standard thermal laminator feeds a document inside a laminating pouch through a set of heated rollers.

These rollers serve two functions simultaneously: they melt the adhesive inside the pouch with consistent heat and apply even pressure to squeeze out air bubbles and bond the plastic to the document.

What a Heat Press Replicates

A heat press replicates the heat part of this equation effectively. However, it applies static, top-down pressure instead of the rolling pressure of a laminator.

This fundamental difference is why your technique is critical to achieving a good result and avoiding common issues like air bubbles.

How to Laminate with a Heat Press

The Essential Materials

Success is impossible without the right supplies. You absolutely must use thermal laminating pouches, which are designed with a heat-activated adhesive.

You will also need a protective layer, such as a Teflon sheet or parchment paper, to place between the laminating pouch and the heat press platen. This prevents any melted plastic from sticking to your machine.

Step 1: Set the Correct Temperature

This is the most critical step. Most laminating pouches are designed to activate between 220°F and 300°F (105°C - 150°C).

Heat presses can get much hotter, so begin at a low temperature around 230°F. You can always press a second time if needed, but you cannot undo a melted pouch.

Always run a test on a non-critical document of similar paper thickness before attempting your final project.

Step 2: Prepare Your Document

Place your document inside the thermal pouch, ensuring even borders on all sides. Place the entire pouch between two sheets of parchment paper or inside a Teflon folder. This "sandwich" protects both your document and your press.

Step 3: Apply Heat and Pressure

Place the prepared sandwich on the lower platen of your heat press.

Apply light to medium pressure for a short duration, typically 10 to 15 seconds. Heavy pressure is not necessary and can cause the melted adhesive to squeeze out the sides.

After pressing, carefully remove the document and place it on a flat surface to cool. Inspect the seal. If you see cloudy or unsealed areas, you can try pressing again for another 5-10 seconds.

Understanding the Trade-offs and Risks

Risk of Overheating and Melting

The primary risk is using too much heat. A heat press is a powerful tool, and excessive temperature will instantly melt the laminating pouch, potentially destroying the document inside and leaving a difficult-to-clean residue on your press platen.

Inconsistent Sealing and Bubbles

Without rollers to force air out, it's easier to trap small air bubbles, resulting in an imperfect finish. This is more common with larger documents where air has further to travel to escape the edges.

Limited to Smaller Items

This technique is most effective for small, flat items like ID cards, business cards, or vaccine cards. Laminating a full 8.5" x 11" document is significantly more challenging, as maintaining even heat and avoiding wrinkles or bubbles becomes much more difficult.

Making the Right Choice for Your Goal

When deciding whether to use your heat press or invest in a laminator, consider the finality and importance of the job.

- If your primary focus is laminating small, non-critical items occasionally: A heat press is a perfectly viable workaround if you are patient and start with low temperatures.

- If your primary focus is achieving a professional, bubble-free finish on important documents: A dedicated thermal laminator is the correct tool and a worthwhile investment for consistent, reliable results.

Ultimately, knowing you can use your heat press for this purpose gives you a versatile tool, but understanding its limitations is key to preventing costly mistakes.

Summary Table:

| Aspect | Heat Press Lamination | Dedicated Laminator |

|---|---|---|

| Pressure Type | Static, top-down | Rolling, even pressure |

| Best For | Small, flat items (e.g., ID cards) | Larger documents, professional finish |

| Risk Level | Higher (melting, bubbles) | Lower (automated consistency) |

| Temperature Control | Manual, requires testing | Pre-set, consistent |

Need a Reliable Heat Press for Your Projects?

While a heat press can handle occasional lamination, consistent results require precision engineering. At KINTEK, we leverage our advanced R&D and in-house manufacturing to deliver high-performance heat presses with exact temperature control—perfect for crafting, apparel, and versatile applications like laminating.

Our equipment ensures even heat distribution and durability, minimizing the risks of melting or uneven seals. Let us help you achieve professional outcomes with a machine built for reliability.

Contact us today to find the perfect heat press solution for your needs!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength

- What is a vacuum press and why is it important in modern manufacturing? Unlock Flawless Bonding and Precision

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing