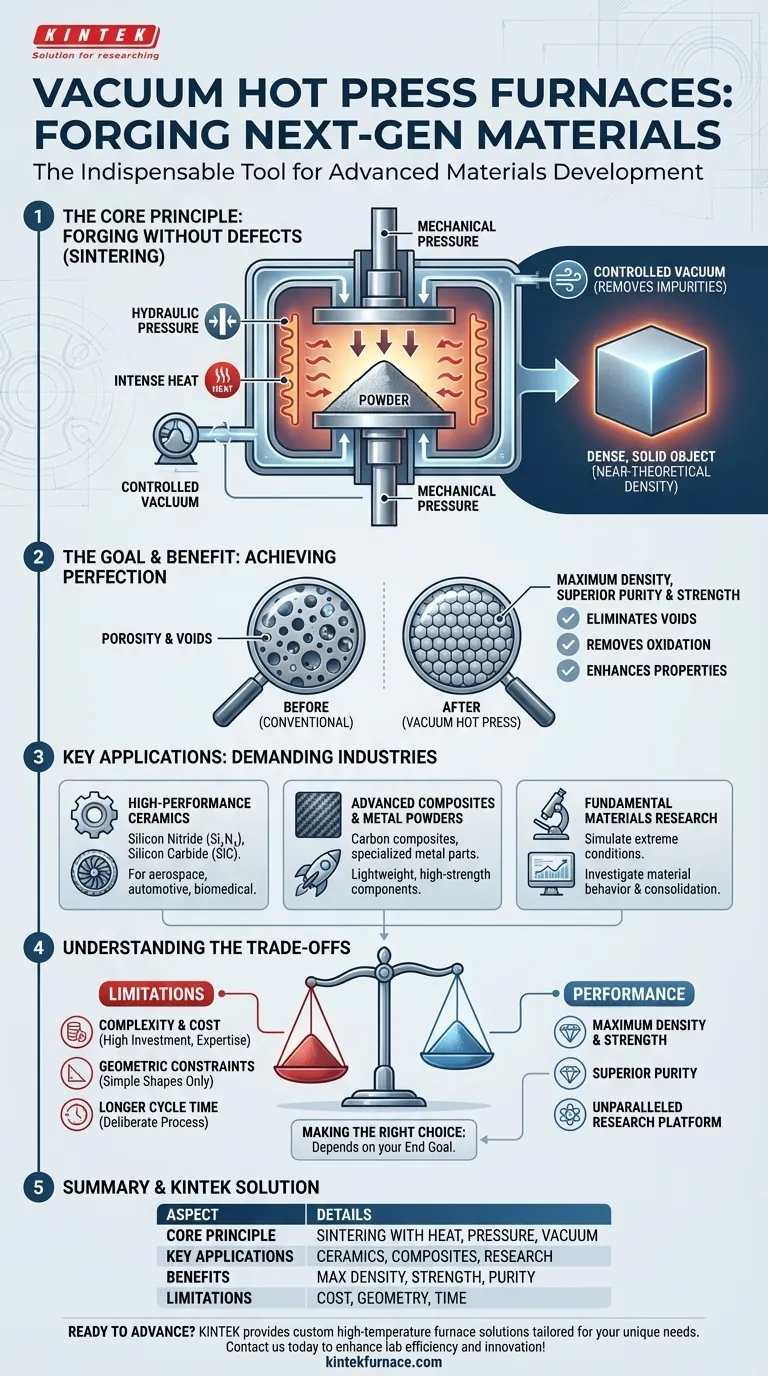

At its core, a vacuum hot press furnace is an indispensable tool that forges next-generation materials by simultaneously applying intense heat, high mechanical pressure, and a controlled vacuum. This unique combination allows scientists and engineers to create components that are exceptionally dense, pure, and strong, with properties that are impossible to achieve through conventional heating or pressing alone.

By eliminating voids and atmospheric impurities during material consolidation, the vacuum hot press furnace enables the creation of materials that approach their theoretical maximum density and performance. It is less a simple oven and more a precision instrument for engineering materials at a fundamental level.

The Core Principle: Forging Materials Without Defects

The primary function of a vacuum hot press furnace is to perform a process called sintering. This involves taking a powder-form material and transforming it into a solid, dense object using heat and pressure.

How It Works: Heat, Pressure, and Vacuum

A vacuum hot press furnace applies three forces simultaneously. Heat provides the energy needed for material particles to bond. Mechanical pressure physically forces the particles together, collapsing pores and voids. The vacuum environment prevents oxidation and removes trapped gases that would otherwise create imperfections.

The Goal: Achieving Near-Theoretical Density

The ultimate objective is to create a material that is as close to 100% dense as possible. Porosity, or the presence of tiny empty spaces, is a primary cause of mechanical failure in advanced materials. By squeezing out these voids, the furnace drastically improves the material's integrity.

The Benefit: Eliminating Porosity and Impurities

The vacuum is critical for high-purity applications. It removes oxygen and other reactive gases that could contaminate the material at high temperatures, ensuring the final product has superior chemical and mechanical properties, such as greater strength and thermal resistance.

Key Applications in Advanced Materials

This technology is not just for theoretical research; it is a cornerstone of production for some of the most demanding industries.

High-Performance Ceramics

Advanced ceramics like silicon nitride (Si₃N₄) and silicon carbide (SiC) are processed in these furnaces. The resulting high-density parts are used in aerospace, automotive, and biomedical applications where resistance to extreme heat, wear, and corrosion is paramount.

Advanced Composites and Metal Powders

The furnace is also essential for creating carbon composite materials and consolidating specialized metal powders. This process is vital for producing lightweight, high-strength components for industries where every gram and every point of strength matters.

Fundamental Materials Research

Beyond production, researchers use hot press furnaces to investigate the fundamental behavior of materials. By precisely controlling temperature and pressure, they can simulate extreme conditions and gain insights into material properties, phase transitions, and consolidation mechanisms.

Understanding the Trade-offs

While powerful, the vacuum hot press process is not a universal solution. Understanding its limitations is key to using it effectively.

Complexity and Cost

These are sophisticated and expensive systems to purchase, operate, and maintain. The precision required for simultaneous control over temperature, pressure, and vacuum demands significant investment and expertise.

Geometric Constraints

The use of direct mechanical pressure means that hot pressing is typically limited to producing parts with relatively simple geometries, such as discs, blocks, or cylinders. Complex, near-net-shape manufacturing is often not feasible.

Process Cycle Time

Compared to other sintering methods that don't involve pressure (like conventional vacuum sintering), the hot press process can have a longer cycle time. The setup, heating, pressing, and cooling phases are deliberate and time-consuming.

Making the Right Choice for Your Goal

Selecting the right material processing method depends entirely on your end goal.

- If your primary focus is achieving maximum material density and strength: The vacuum hot press is the definitive tool for critical applications where performance cannot be compromised.

- If your primary focus is fundamental research: The furnace provides an unparalleled platform for studying material consolidation and behavior under precisely controlled, extreme conditions.

- If your primary focus is cost-effective, high-volume production: You must weigh the superior properties of a hot-pressed part against the higher costs and slower cycle times compared to other methods.

Ultimately, the vacuum hot press furnace empowers scientists and engineers to move beyond conventional material limitations and create the building blocks for the next generation of technology.

Summary Table:

| Aspect | Details |

|---|---|

| Core Principle | Sintering with heat, pressure, and vacuum to eliminate porosity and impurities. |

| Key Applications | High-performance ceramics, advanced composites, metal powders, and materials research. |

| Benefits | Achieves near-theoretical density, enhances strength, thermal resistance, and purity. |

| Limitations | High cost, complex operation, geometric constraints, and longer cycle times. |

Ready to advance your materials development with precision-engineered solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for your unique experimental needs. Our deep customization capabilities ensure optimal performance for applications in ceramics, composites, and more. Contact us today to discuss how we can enhance your lab's efficiency and innovation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density