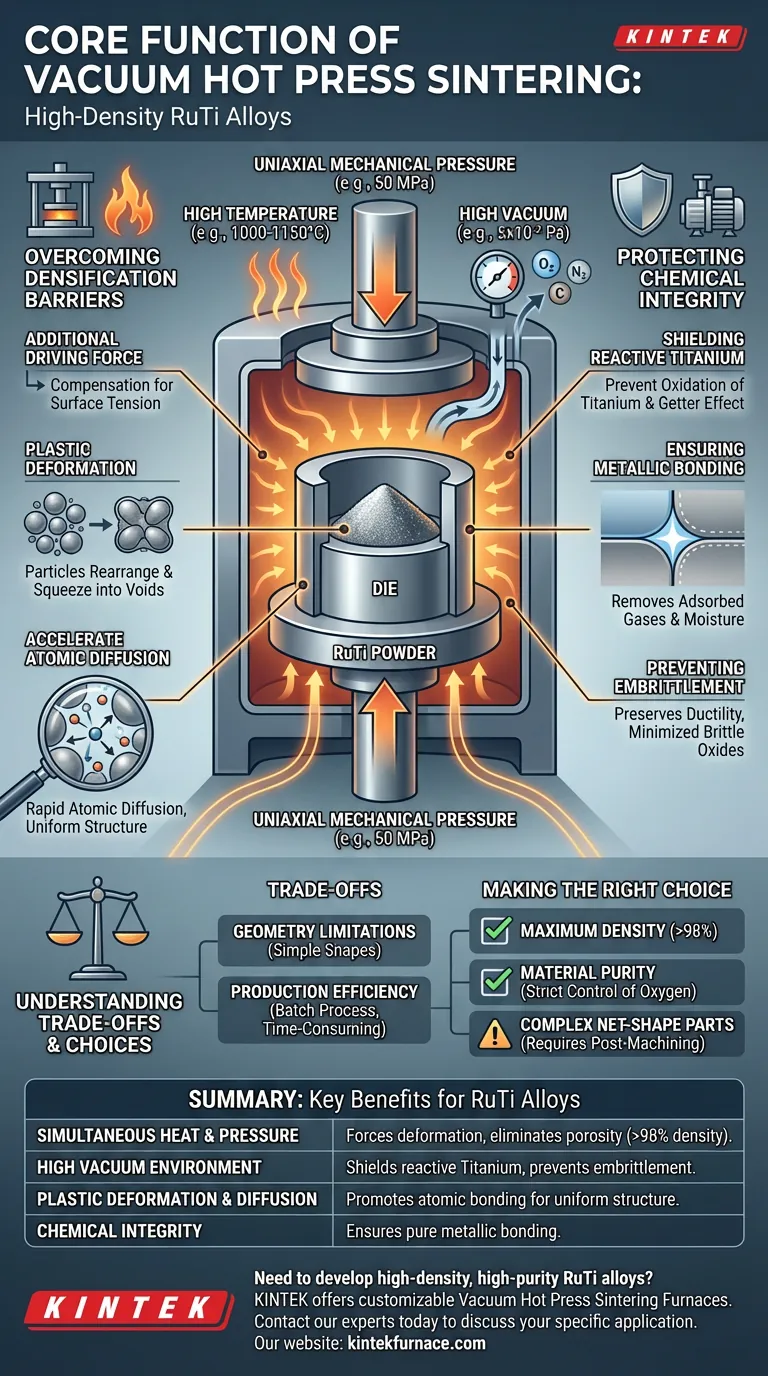

The core function of a vacuum hot press sintering furnace is the simultaneous application of high temperature, high vacuum, and uniaxial mechanical pressure. Specifically for RuTi (Ruthenium-Titanium) alloys, this equipment acts as a forced densification system. It overcomes the natural resistance of refractory materials to sinter by physically crushing powder particles together while chemically shielding the highly reactive titanium from oxidation.

The Bottom Line: Conventional heating is often insufficient to densify refractory RuTi alloys due to high surface tension and material hardness. Vacuum hot pressing provides the necessary external driving force (pressure) to achieve near-theoretical density, while the vacuum environment prevents the formation of brittle oxides that would ruin the alloy's ductility.

Overcoming the Barriers to Densification

For refractory alloys like RuTi, achieving high density is a contest against the material's own physical properties. The furnace serves as a tool to bypass these natural limitations through mechanical force.

Providing Additional Driving Force

In conventional sintering, particles bond solely through thermal energy. For RuTi, this is often insufficient to overcome surface tension.

The furnace applies significant mechanical pressure (e.g., 50 MPa). This acts as an external driving force that effectively compensates for neutralized surface tension.

Promoting Plastic Deformation

The combination of heat (e.g., 1000-1150°C) and pressure forces the metal powder particles to physically rearrange.

This leads to significant plastic deformation at the contact points. The particles are squeezed into voids, effectively eliminating porosity and creating a solid, high-density block.

Accelerating Atomic Diffusion

Pressure does not just squeeze the material; it activates kinetics.

By increasing the contact area between particles, the furnace facilitates rapid atomic diffusion. This ensures strong metallurgical bonding and promotes the formation of a uniform, high-hardness alloy structure.

Protecting Chemical Integrity

The "Vacuum" component of the furnace is just as critical as the "Press," particularly because Titanium is involved.

Shielding Reactive Titanium

Titanium and its alloys are extremely sensitive to interstitial elements like Oxygen, Nitrogen, and Carbon at high temperatures.

Without a vacuum, Titanium acts as a "getter," absorbing these gases. This leads to contamination and the formation of brittle compounds that degrade the alloy's mechanical properties.

Ensuring Metallic Bonding

The high vacuum environment (e.g., 5x10⁻² Pa) actively cleans the material during the process.

It removes adsorbed gases and moisture from the surface of the pre-alloyed powders. This purification of the interfaces ensures that when particles touch, they form a true metallic bond rather than being separated by an oxide layer.

Preventing Embrittlement

By isolating the alloy from impurity gases, the furnace preserves the ductility of the RuTi alloy.

This minimizes the risk of the material becoming brittle during the cooling phase, ensuring the final product retains both high hardness and the necessary structural integrity.

Understanding the Trade-offs

While vacuum hot pressing is superior for density and purity, it is not without operational constraints.

Geometry Limitations The process utilizes a uniaxial press (pressure from top and bottom). This limits production to simple shapes, such as discs, cylinders, or blocks. Complex geometries usually require secondary machining.

Production Efficiency This is a batch process. The heating, pressing, and cooling cycles can be time-consuming compared to continuous sintering methods. It is optimized for material quality, not high-volume throughput.

Making the Right Choice for Your Goal

When deciding if this process fits your manufacturing needs, consider your primary performance metrics.

- If your primary focus is Maximum Density: Rely on vacuum hot pressing to achieve >98% relative density and mechanical properties comparable to forged materials.

- If your primary focus is Material Purity: Use this method to strictly control oxygen content and prevent the formation of brittle impurity phases in Titanium-based alloys.

- If your primary focus is Complex Net-Shape Parts: Be aware that this method will require significant post-process machining; alternative methods like MIM (Metal Injection Molding) might offer better shaping but lower density.

Ultimately, for RuTi alloys, the vacuum hot press is the definitive solution for converting loose powder into a structural component without compromising chemical purity.

Summary Table:

| Function | Key Benefit for RuTi Alloys |

|---|---|

| Simultaneous Heat & Pressure | Forces particle deformation and eliminates porosity for >98% density. |

| High Vacuum Environment | Shields reactive titanium from oxygen/nitrogen, preventing embrittlement. |

| Plastic Deformation & Diffusion | Promotes atomic bonding for a uniform, high-hardness structure. |

| Chemical Integrity | Ensures pure metallic bonding by removing surface gases and moisture. |

Need to develop high-density, high-purity RuTi alloys or other advanced materials?

Backed by expert R&D and manufacturing, KINTEK offers a range of Vacuum Hot Press Sintering Furnaces, all customizable for your unique material science challenges. Our systems are engineered to deliver the precise combination of temperature, vacuum, and pressure required for superior results.

Contact our experts today to discuss how we can optimize a vacuum hot press solution for your specific application.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering