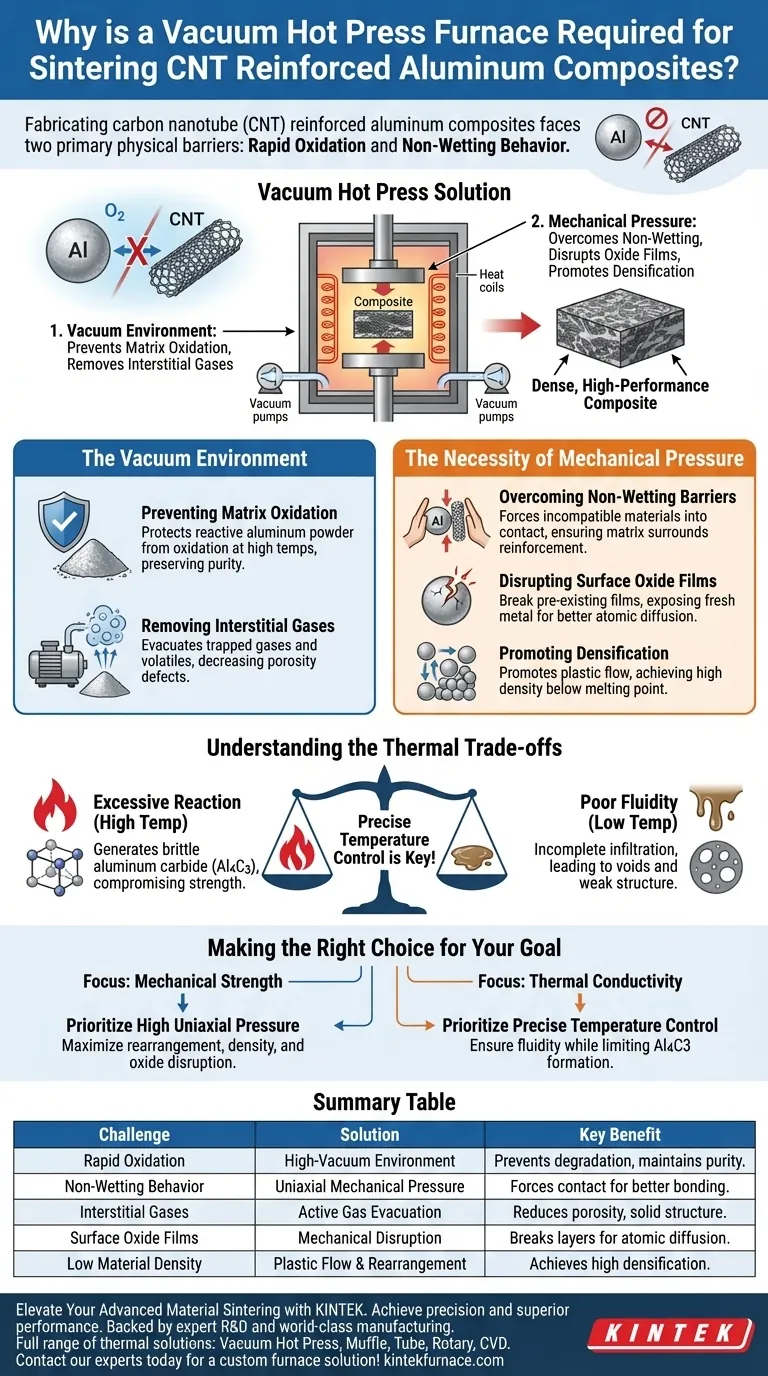

Fabricating carbon nanotube (CNT) reinforced aluminum composites requires overcoming two specific physical barriers: rapid oxidation and non-wetting behavior. A vacuum hot press furnace addresses these simultaneously by maintaining an oxygen-free environment to prevent the aluminum from degrading, while applying uniaxial pressure to force the materials together. This combination promotes plastic flow and particle rearrangement, ensuring a dense, high-performance composite.

The vacuum hot press furnace is essential because it solves the inherent incompatibility between aluminum and carbon nanotubes. By integrating a vacuum environment with mechanical pressure, it prevents matrix oxidation and forcibly overcomes non-wetting issues to achieve high material density and strong interfacial bonding.

The Critical Role of the Vacuum Environment

Preventing Matrix Oxidation

The primary function of the vacuum is to protect the aluminum matrix. Aluminum powder is highly reactive and susceptible to oxidation at high temperatures.

Without a vacuum, an oxide layer would form immediately, degrading the material properties and hindering the sintering process. The vacuum environment effectively eliminates oxygen, preserving the purity of the aluminum.

Removing Interstitial Gases

Beyond preventing oxidation, the vacuum actively evacuates gases trapped in the interstitial spaces between powder particles.

It also removes volatiles released during the heating process. This reduction in gas entrapment significantly decreases porosity defects within the final sintered body, leading to a more solid structure.

The Necessity of Mechanical Pressure

Overcoming Non-Wetting Barriers

One of the hardest challenges in this composite is that aluminum and carbon nanotubes do not naturally adhere well to each other; they exhibit non-wetting behavior.

Uniaxial mechanical pressure is required to physically force the aluminum powder and nanotubes into contact. This pressure overcomes the resistance caused by non-wetting, ensuring the matrix effectively surrounds the reinforcement.

Disrupting Surface Oxide Films

Even with a vacuum, pre-existing oxide films may exist on particle surfaces. Mechanical pressure helps forcibly disrupt these films.

Breaking these layers exposes fresh metal surfaces, which enhances atomic diffusion and improves the bonding strength between the aluminum matrix and the nanotubes.

Promoting Densification

The application of pressure promotes the plastic flow and rearrangement of powder particles.

This mechanism allows the material to achieve high density even at temperatures below the melting point of aluminum, creating a compact and robust composite.

Understanding the Thermal Trade-offs

The Risk of Excessive Reaction

While high temperature is necessary for sintering, it introduces a critical trade-off known as interfacial chemical reactivity.

If the temperature is uncontrolled or too high, severe reactions can occur between the aluminum and the carbon nanotubes. This generates excessive aluminum carbide ($Al_4C_3$), a brittle compound that compromises the material's thermal conductivity and mechanical strength.

Balancing Fluidity and Infiltration

Conversely, if the temperature is too low, the aluminum matrix will exhibit poor fluidity.

This results in incomplete infiltration of the nanotubes, leading to voids and weak structural integrity. Precise temperature control is therefore required to balance sufficient flow against the risk of harmful chemical reactions.

Making the Right Choice for Your Goal

To maximize the quality of your carbon nanotube reinforced aluminum composites, tailor your process parameters to your specific performance objectives:

- If your primary focus is mechanical strength: Prioritize high uniaxial pressure to maximize particle rearrangement and density, ensuring the disruption of oxide films for better bonding.

- If your primary focus is thermal conductivity: Prioritize precise temperature control to ensure matrix fluidity while strictly limiting the formation of brittle aluminum carbide ($Al_4C_3$) at the interface.

Success relies on using the furnace not just to heat, but to forcefully integrate incompatible materials in a pristine environment.

Summary Table:

| Challenge in CNT-Al Sintering | Vacuum Hot Press Solution | Key Benefit |

|---|---|---|

| Rapid Oxidation | High-Vacuum Environment | Prevents aluminum degradation and maintains purity. |

| Non-Wetting Behavior | Uniaxial Mechanical Pressure | Forces contact between Al and CNTs for better bonding. |

| Interstitial Gases | Active Gas Evacuation | Reduces porosity defects and ensures a solid structure. |

| Surface Oxide Films | Mechanical Disruption | Breaks oxide layers to enhance atomic diffusion. |

| Low Material Density | Plastic Flow & Rearrangement | Achieves high densification below melting points. |

Elevate Your Advanced Material Sintering with KINTEK

Achieve precision and superior performance in your composite manufacturing. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of thermal solutions, including Vacuum Hot Press Furnaces, Muffle, Tube, Rotary, and CVD systems.

Whether you are refining carbon nanotube reinforcements or developing next-generation alloys, our lab high-temp furnaces are fully customizable to meet your unique research and production needs. Don't let oxidation or poor bonding compromise your results—partner with KINTEK for reliable, high-density material outcomes.

Contact our experts today to find your custom furnace solution!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the core function of a vacuum hot pressing furnace? Expert Guide to TiAl/Ti6Al4V Composite Success

- What is hot pressing sintering and how does vacuum hot pressing sintering improve the process? Achieve Superior Material Density and Purity

- What are the key benefits of using a vacuum press for sintering metal and ceramic powders? Achieve Superior Density and Purity

- What are the advantages of using a vacuum hot pressing furnace compared to explosive cladding? Get Precision Results

- How are vacuum hot pressing sintering furnaces classified based on temperature? Explore Low, Medium, and High-Tier Solutions

- What are the core functions of a vacuum hot pressing furnace in the densification of Cr2AlC ceramics?

- Why is Vacuum Hot Press equipment considered a cornerstone of modern manufacturing? Unlock Superior Material Density and Purity

- How is Vacuum Hot Press equipment utilized in the aerospace industry? Essential for High-Performance Component Manufacturing