In short, Vacuum Hot Press equipment is a cornerstone of modern manufacturing because it uniquely combines high heat, immense pressure, and a controlled vacuum atmosphere. This synergy creates materials with exceptional density, strength, and purity that are impossible to achieve with conventional methods, directly enabling the production of critical components for high-stakes industries like aerospace, medical, and energy.

The core challenge in advanced manufacturing is not just shaping materials, but controlling their internal structure at a microscopic level. Vacuum Hot Pressing solves this by removing atmospheric contaminants and gases, allowing for the perfect consolidation of materials into a dense, defect-free final state.

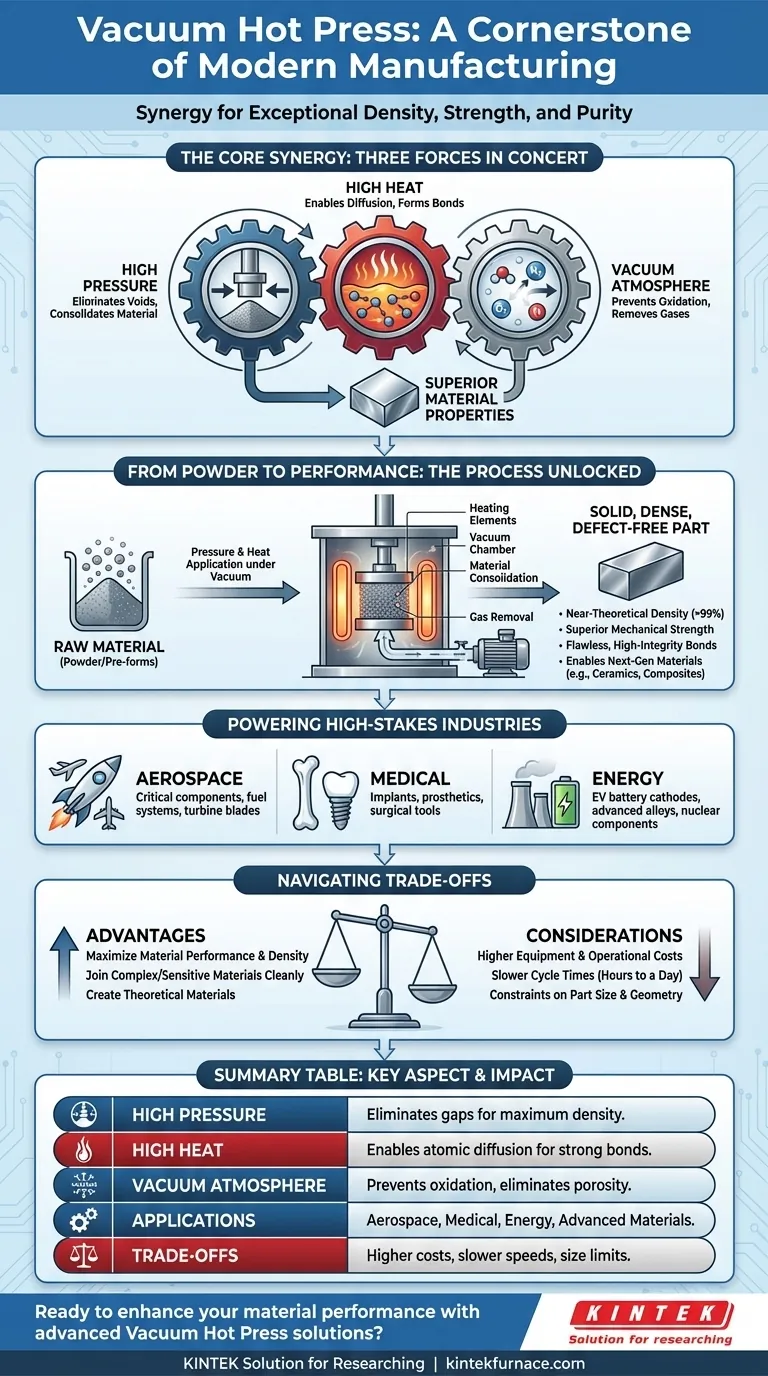

The Core Principle: A Synergy of Forces

Vacuum Hot Pressing isn't just about heating and squeezing a material. It's the precise combination of three environmental factors working in concert, each solving a specific problem.

The Role of High Pressure

Pressure is the primary force for consolidation. By applying immense, uniform force, the equipment physically presses material powders or pre-forms together, eliminating the gaps and voids between particles. This mechanical force is the first step toward achieving maximum density.

The Role of High Heat

Heat provides the energy for diffusion and bonding. As the temperature rises, atoms at the surface of the material particles become more mobile. This allows them to move across boundaries and form strong, permanent metallurgical or ceramic bonds, transforming a compressed powder into a solid, monolithic part.

The Critical Role of the Vacuum

The vacuum is the game-changer that elevates the process. Pulling a vacuum removes atmospheric gases—primarily oxygen and nitrogen—from the chamber. This has two critical effects:

- Prevents Oxidation and Contamination: Without oxygen, sensitive materials like titanium or advanced alloys can be processed at high temperatures without forming brittle oxide layers, which degrade performance.

- Eliminates Porosity: The vacuum extracts trapped gases from within the material as it's being pressed. This prevents the formation of microscopic air pockets (porosity), a common defect that severely weakens components.

Why This Process Unlocks Advanced Applications

The ability to control pressure, heat, and atmosphere simultaneously allows for material properties that are otherwise unattainable. This directly translates into components that are stronger, lighter, and more reliable.

Achieving Near-Theoretical Density

By eliminating porosity, Vacuum Hot Pressing can produce parts that are over 99% dense. This extreme density is directly linked to superior mechanical strength, hardness, and wear resistance, which is critical for components like brake pads, cutting tools, and body armor.

Creating Flawless, High-Integrity Bonds

In processes like diffusion bonding and vacuum brazing, the pristine vacuum environment is essential. It allows for the joining of dissimilar or complex materials without the use of flux, which can introduce contaminants. This results in clean, strong, and leak-proof joints vital for aerospace fuel systems and medical implants.

Fabricating Next-Generation Materials

Many advanced materials, such as technical ceramics and metal-matrix composites, cannot be effectively processed in the open air. Vacuum Hot Pressing provides the controlled environment needed to sinter these materials, enabling innovations in everything from EV battery cathodes to turbine blades.

Understanding the Trade-offs

While powerful, Vacuum Hot Pressing is a specialized process with specific considerations. It is not a universal replacement for all manufacturing techniques.

Higher Equipment and Operational Costs

Vacuum Hot Press systems are complex and expensive to acquire and maintain compared to standard hydraulic presses or conventional furnaces. The need for robust vacuum pumps and precise controls adds to the initial investment and operational overhead.

Slower Cycle Times

Heating a component, applying pressure, holding it at temperature, and cooling it down—all within a vacuum—is an inherently slow process. Cycle times can range from several hours to a full day, making it unsuitable for high-volume, low-cost commodity production.

Constraints on Part Size and Geometry

The size of the final component is limited by the dimensions of the press chamber and the capabilities of the heating elements. While large presses exist, they represent a significant capital investment.

Making the Right Choice for Your Goal

Ultimately, the decision to use a Vacuum Hot Press depends on the final performance requirements of your component.

- If your primary focus is maximum material performance and density: Vacuum Hot Pressing is the gold standard for creating components with the highest possible strength, hardness, and reliability.

- If your primary focus is joining complex or sensitive materials without contamination: The vacuum environment is non-negotiable for achieving clean, high-integrity bonds through processes like diffusion bonding or vacuum brazing.

- If your primary focus is high-volume, low-cost production of simple parts: You must weigh the significant performance gains against the higher costs and slower cycle times of Vacuum Hot Pressing.

This technology empowers engineers and scientists to create materials that were once only theoretical, making it an indispensable tool for building the future.

Summary Table:

| Key Aspect | Description |

|---|---|

| High Pressure | Eliminates gaps and voids for maximum density and consolidation. |

| High Heat | Enables atomic diffusion and bonding for solid, monolithic parts. |

| Vacuum Atmosphere | Prevents oxidation, removes gases, and eliminates porosity for purity. |

| Applications | Used in aerospace, medical implants, energy components, and advanced materials. |

| Trade-offs | Higher costs, slower cycle times, and size constraints compared to conventional methods. |

Ready to enhance your material performance with advanced Vacuum Hot Press solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior density, strength, and purity. Contact us today to discuss how we can support your high-stakes manufacturing goals!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing