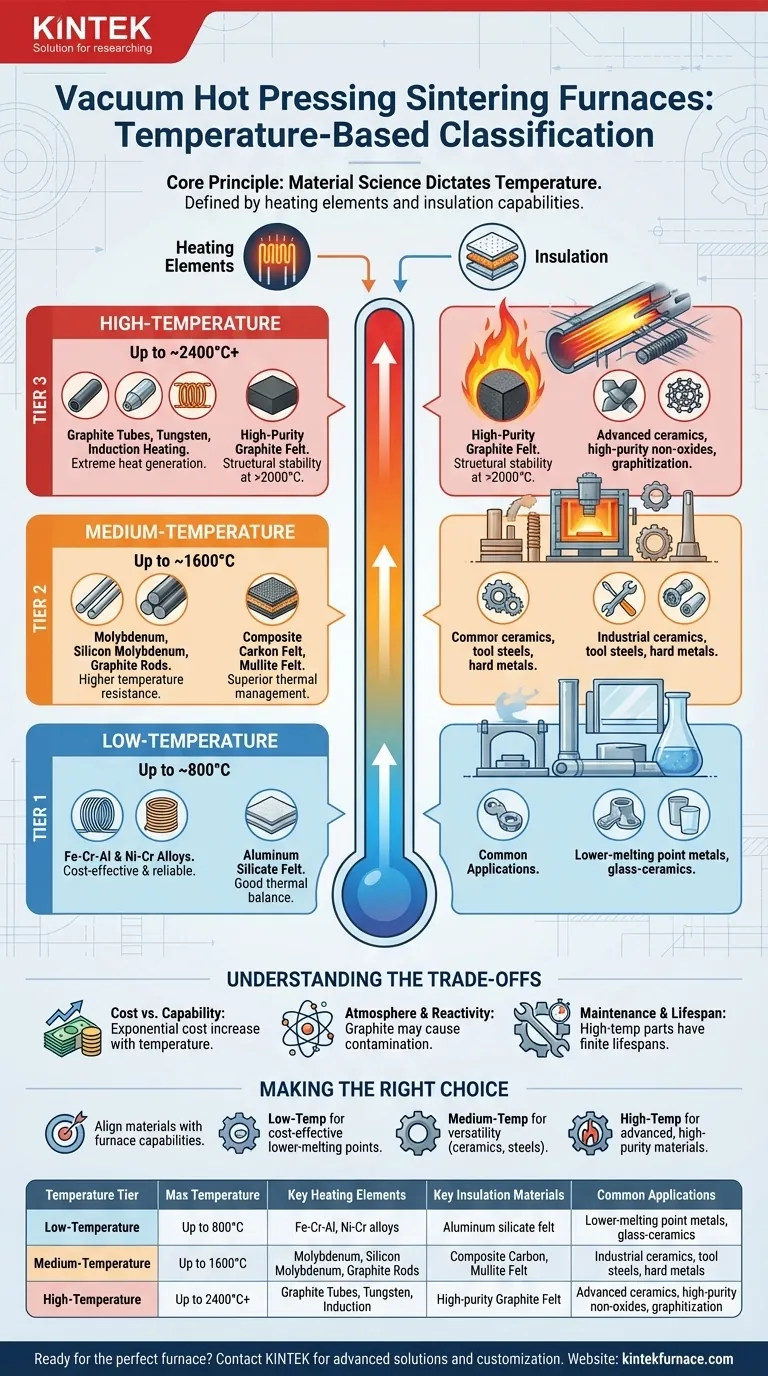

At its core, a vacuum hot pressing sintering furnace is classified into three functional tiers based on its maximum operating temperature. These categories are generally defined as low-temperature (up to 800°C), medium-temperature (up to 1600°C), and high-temperature (up to 2400°C or higher). This classification is not arbitrary; it is a direct consequence of the material science governing the furnace's most critical components.

The temperature rating of a vacuum hot press is fundamentally determined by the materials used for its heating elements and insulation. As the target temperature increases, the materials required to generate and contain that heat become progressively more specialized, complex, and costly.

The Core Principle: Material Science Dictates Temperature

Understanding the temperature classification of these furnaces is less about memorizing numbers and more about understanding the physical limits of the materials used to build them. A furnace cannot operate at a temperature that would destroy its own core components.

The Two Critical Components

The entire design hinges on two parts: the heating elements, which generate the thermal energy, and the insulation, which contains it. The choice of materials for these two components dictates the furnace's maximum safe operating temperature.

A Breakdown of the Temperature Tiers

Each temperature tier represents a significant shift in the materials technology required for stable and reliable operation in a vacuum environment.

Low-Temperature Furnaces (Up to ~800°C)

This tier is designed for processes involving materials with lower melting or sintering points.

- Heating Elements: The workhorses here are common resistance heating alloys like iron-chromium aluminum (Fe-Cr-Al) or nickel-chromium (Ni-Cr) wires. These are cost-effective and reliable within their temperature range.

- Insulation: High-temperature aluminum silicate felt is typically sufficient to contain the heat generated, providing an excellent balance of thermal performance and cost.

Medium-Temperature Furnaces (Up to ~1600°C)

This is the most common range for sintering a wide variety of industrial ceramics and metals. The material requirements take a significant step up.

- Heating Elements: To reach 1600°C, furnaces must use more robust materials like metallic molybdenum, silicon molybdenum rods, silicon carbon rods, or graphite rods. These can withstand much higher temperatures before degrading.

- Insulation: Standard silicate felts are no longer viable. Instead, these furnaces rely on superior insulators like composite carbon felt, mullite felt, or graphite felt to manage the intense heat.

High-Temperature Furnaces (Up to ~2400°C and Beyond)

This tier is reserved for advanced materials processing where extreme temperatures are required. The engineering and material science are at their most demanding.

- Heating Methods: Traditional resistance rods are often insufficient. These furnaces use graphite tubes, pure tungsten elements, or non-contact induction heating. Induction heating uses electromagnetic fields to directly heat the conductive material or a graphite susceptor, bypassing the limits of conventional elements.

- Insulation: At these temperatures, high-purity graphite felt is the industry standard. It is one of the few materials that remains structurally stable and provides effective insulation in a vacuum at temperatures exceeding 2000°C.

Understanding the Trade-offs

Choosing a furnace is not simply about picking the highest temperature. Each tier comes with critical trade-offs that impact cost, maintenance, and process suitability.

Cost vs. Capability

The relationship between temperature and cost is exponential. The exotic materials required for high-temperature operation—like tungsten and high-purity graphite—are significantly more expensive than the alloys used in low-temperature furnaces. The complexity of the power supply and control systems also increases dramatically.

Atmosphere and Reactivity

The material of the heating element is not inert. In the vacuum environment, it can interact with the material being processed (the "workpiece"). Graphite elements, for instance, are excellent for carbon-neutral or reducing atmospheres but can cause carbon contamination in highly sensitive materials.

Maintenance and Lifespan

High-temperature components have a finite lifespan. Tungsten elements can become brittle, and graphite components can degrade over time, especially if exposed to trace amounts of oxygen. The cost and downtime associated with replacing these parts are a major operational consideration.

Making the Right Choice for Your Goal

Your choice of furnace must be driven by the specific requirements of the materials you intend to process.

- If your primary focus is sintering lower-melting point metals or certain glass-ceramics: A low-temperature furnace (up to 800°C) offers the most cost-effective and reliable solution.

- If your primary focus is processing most industrial ceramics, tool steels, or hard metals: A medium-temperature furnace (up to 1600°C) provides the necessary versatility and performance for a wide range of applications.

- If your primary focus is developing advanced ceramics, high-purity non-oxides, or performing graphitization: A high-temperature furnace (2400°C+) is essential, but you must budget for its higher acquisition and operational costs.

Ultimately, selecting the right furnace is about aligning the material science of your process with the material science of the equipment itself.

Summary Table:

| Temperature Tier | Max Temperature | Key Heating Elements | Key Insulation Materials | Common Applications |

|---|---|---|---|---|

| Low-Temperature | Up to 800°C | Fe-Cr-Al, Ni-Cr alloys | Aluminum silicate felt | Lower-melting point metals, glass-ceramics |

| Medium-Temperature | Up to 1600°C | Molybdenum, silicon molybdenum rods, graphite rods | Composite carbon felt, mullite felt | Industrial ceramics, tool steels, hard metals |

| High-Temperature | Up to 2400°C+ | Graphite tubes, tungsten elements, induction heating | High-purity graphite felt | Advanced ceramics, high-purity non-oxides, graphitization |

Ready to find the perfect vacuum hot pressing sintering furnace for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your material processing efficiency and results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy