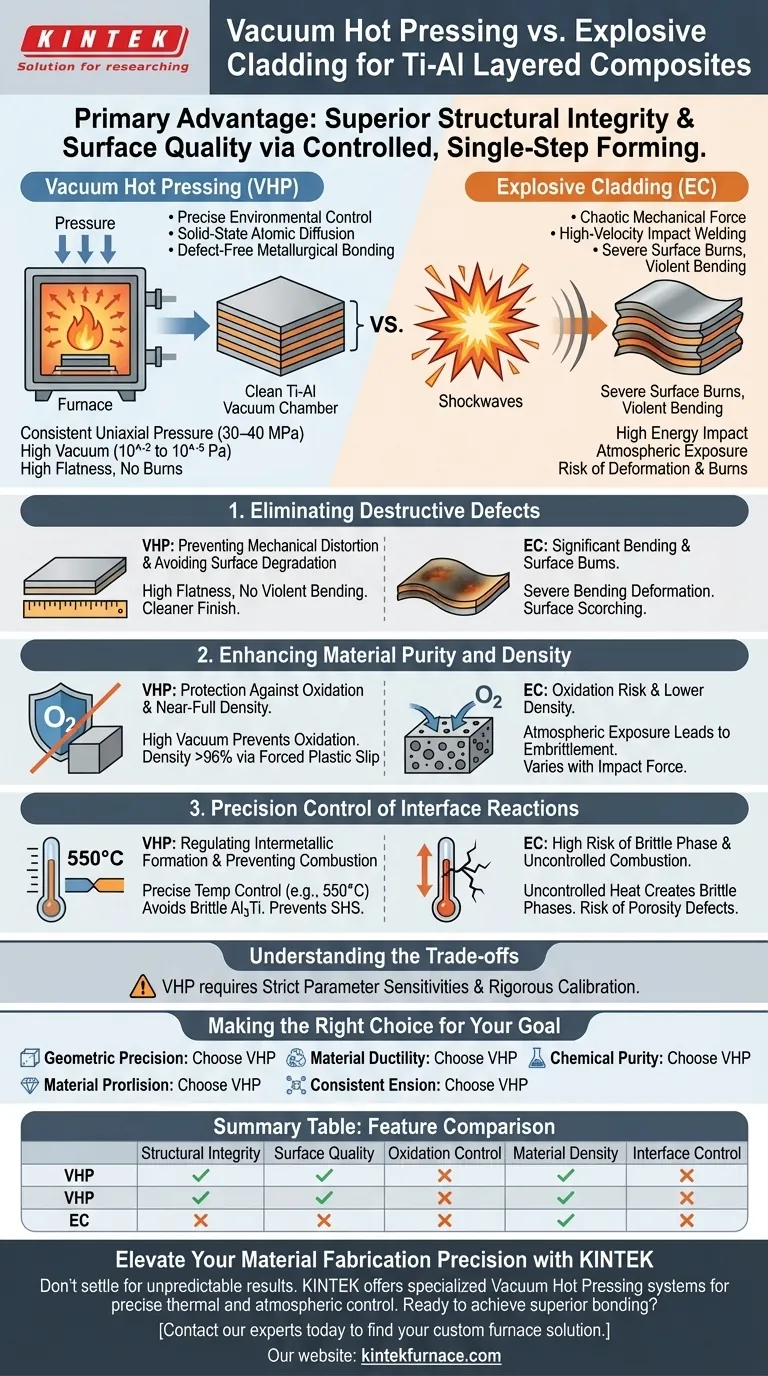

The primary advantage of using a vacuum hot pressing furnace for Ti-Al layered composites is the ability to achieve superior structural integrity and surface quality through a controlled, single-step forming process. Unlike explosive cladding, which utilizes high-velocity impact, vacuum hot pressing avoids severe surface burns and violent bending deformation, delivering a final product with high flatness and uniform interface bonding.

Core Takeaway: Vacuum hot pressing replaces the chaotic mechanical force of explosive cladding with precise environmental control, enabling defect-free metallurgical bonding through solid-state atomic diffusion rather than impact welding.

Eliminating Destructive Defects

This section addresses the physical quality of the composite, focusing on the reduction of macroscopic flaws inherent to explosive methods.

Preventing Mechanical Distortion

Explosive cladding relies on shock waves that can cause substantial deformation of the metal layers. Vacuum hot pressing applies consistent, uniaxial mechanical pressure (e.g., 30–40 MPa). This ensures the final laminate maintains high flatness without the violent bending associated with explosive processing.

Avoiding Surface Degradation

The high energy of explosive cladding can scorch or damage the material surface. Hot pressing occurs in a controlled thermal environment, eliminating the risk of surface burns. This results in a cleaner finish that requires less post-process machining or correction.

Enhancing Material Purity and Density

While explosive cladding bonds materials instantly, it lacks the environmental control necessary for reactive metals like Titanium.

Protection Against Oxidation

Titanium powder and foils are extremely sensitive to oxygen, which causes embrittlement. The high vacuum environment (e.g., 10^-2 to 10^-5 Pa) prevents oxidation during the heating phase. This ensures the mechanical properties of the titanium remain uncompromised by oxygen contamination.

Achieving Near-Full Density

Standard sintering often leaves pores, resulting in lower density (around 71%). The combination of heat and forced plastic slip from mechanical pressure excludes internal pores and gaps. This allows the composite to approach a fully dense state (often exceeding 96%) with tight microscopic contact between layers.

Precision Control of Interface Reactions

The most critical advantage of the furnace is the ability to fine-tune the chemical interaction between layers, which is difficult to control in explosive cladding.

Regulating Intermetallic Formation

The bond between Titanium and Aluminum depends heavily on temperature; excessive heat creates brittle phases. Precise furnace control allows you to hold temperatures at optimal bonding points (e.g., 550°C) while avoiding higher thresholds (e.g., 600°C) where brittle Al3Ti compounds form. This prevents the cracking and reduced plasticity often seen when reaction temperatures are uncontrolled.

Preventing Uncontrolled Combustion

Specific temperature windows determine the reaction mechanism. A controlled semi-solid reaction yields a dense structure, whereas a slight overshoot can trigger Self-Propagating High-Temperature Synthesis (SHS). The furnace's ability to "lock" the reaction window prevents these combustion reactions, which would otherwise lead to significant porosity defects.

Understanding the Trade-offs

While vacuum hot pressing offers superior quality, it introduces strict process sensitivities that must be managed.

Sensitivity to Parameter Deviations

Unlike the "force-based" nature of explosive cladding, hot pressing is scientifically delicate. As noted, a temperature deviation of just 45°C (e.g., from 665°C to 710°C) can shift the process from successful bonding to a defect-ridden combustion reaction. Operators must maintain rigorous equipment calibration to avoid material performance degradation caused by temperature overshoot.

Making the Right Choice for Your Goal

Vacuum hot pressing is the superior choice when material performance and geometric precision are non-negotiable.

- If your primary focus is Geometric Precision: Choose vacuum hot pressing to ensure high flatness and avoid the bending deformation typical of explosive impact.

- If your primary focus is Material Ductility: Rely on the furnace's precise temperature control to prevent the formation of brittle Al3Ti intermetallics that cause cracking.

- If your primary focus is Chemical Purity: Leverage the vacuum environment to prevent oxidation in titanium layers and eliminate volatile impurities.

By prioritizing environmental control over mechanical force, vacuum hot pressing transforms the volatile process of combining reactive metals into a predictable, high-precision manufacturing capability.

Summary Table:

| Feature | Vacuum Hot Pressing | Explosive Cladding |

|---|---|---|

| Structural Integrity | High flatness; no bending | Significant bending deformation |

| Surface Quality | No burns; clean finish | Risk of severe surface burns |

| Oxidation Control | High vacuum environment | Atmospheric exposure |

| Material Density | Near-full density (>96%) | Varies with impact force |

| Interface Control | Precise intermetallic regulation | High risk of brittle phase formation |

Elevate Your Material Fabrication Precision with KINTEK

Don't settle for the unpredictable results of explosive cladding. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum Hot Pressing systems, Muffle, Tube, Rotary, and CVD furnaces—all customizable to your unique research or production needs. Our high-temp solutions provide the precise thermal and atmospheric control required to eliminate brittle phases and prevent oxidation in reactive metals like Titanium.

Ready to achieve superior bonding and near-full density?

Contact our experts today to find your custom furnace solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is vacuum hot pressing (VHP) and what materials is it suitable for? Unlock High-Density Material Solutions

- What role do graphite molds play in ZnS vacuum hot pressing? Optimize Densification and Optical Purity

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What core functions do high-purity graphite molds perform during the SPS of LaFeO3? Optimize Your Sintering Process

- What is the function of graphite dies in vacuum hot pressing? Optimize Austenitic Stainless Steel Sintering Results

- How does the high vacuum environment provided by a vacuum hot press furnace influence the properties of Cu/rGO composites? Achieve Superior Composite Performance

- What are the key components of a vacuum hot press? Master Temperature, Pressure, and Atmosphere Control

- Why must hot press sintering equipment possess high vacuum environment control capabilities when preparing copper-based composites? Ensure Purity, Bonding, and Performance