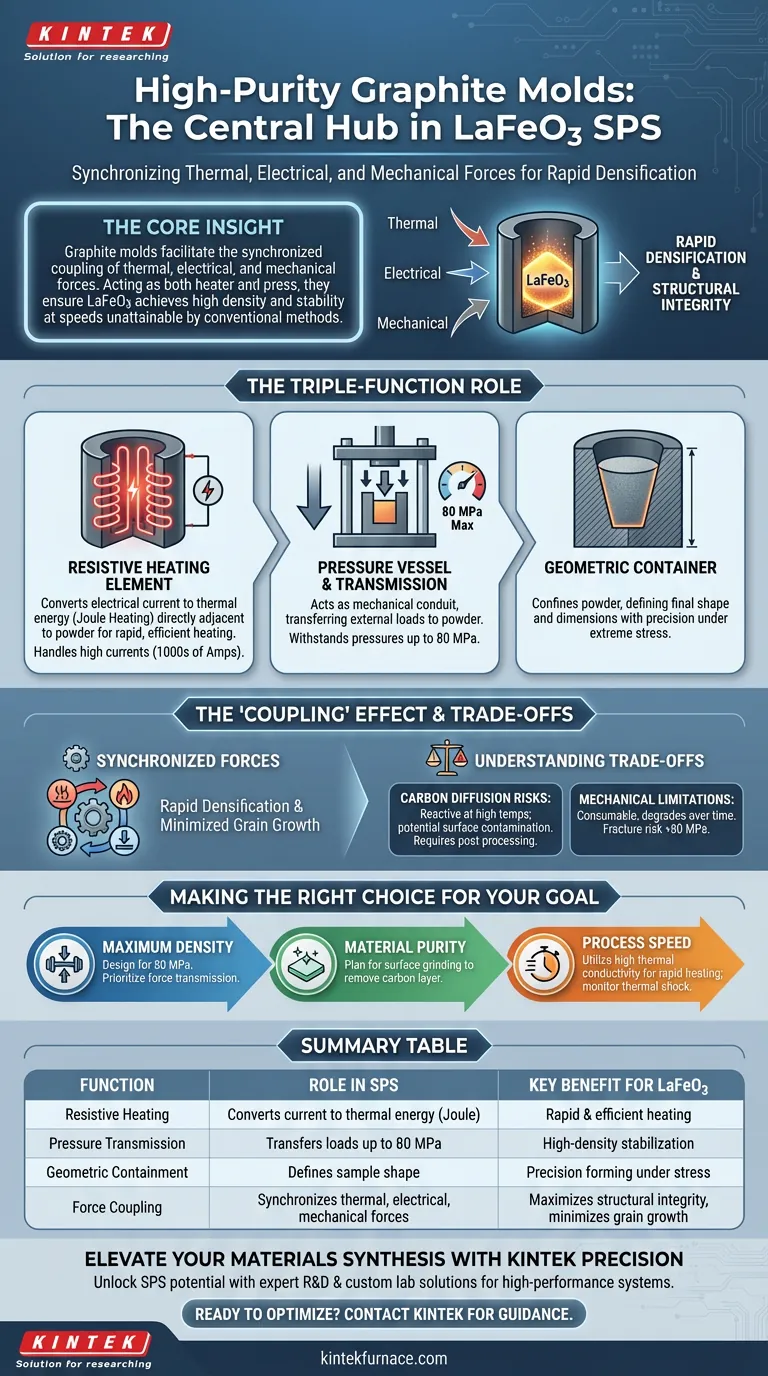

High-purity graphite molds act as the central operational hub during the Spark Plasma Sintering (SPS) of LaFeO3, serving three simultaneous functions that are critical to the process's success. They function as a geometric container to define the sample's shape, a resistive heating element that converts electrical current into thermal energy, and a pressure vessel capable of transmitting significant mechanical force. This multi-functional role allows for the rapid, high-pressure densification required to stabilize LaFeO3 ceramics.

The Core Insight Graphite molds do not merely hold the material; they facilitate the synchronized coupling of thermal, electrical, and mechanical forces. By acting as both the heater and the press, the mold ensures that LaFeO3 powder achieves high density and structural stability at speeds unattainable by conventional sintering methods.

The Triple-Function Role of Graphite

Acting as a Resistive Heater

In standard sintering, the heat source is external. In SPS, the graphite mold itself is the heating element.

Because graphite is electrically conductive, it allows high currents (often thousands of amperes) to pass through the mold assembly.

The material's natural electrical resistance converts this current into heat via the Joule heating effect. This allows thermal energy to be generated immediately adjacent to the LaFeO3 powder, ensuring rapid and efficient heating.

Transmitting Mechanical Pressure

LaFeO3 requires significant pressure to achieve high density. The graphite mold acts as the transmission medium for this force.

It serves as a mechanical conduit, transferring external loads from the machine's rams directly to the powder particles.

According to technical data, these molds effectively withstand and transmit mechanical pressures up to 80 MPa during the LaFeO3 sintering process without structural failure.

Defining Geometry and Containment

At a foundational level, the mold acts as the forming tool.

It confines the loose LaFeO3 powder, defining the final physical shape and dimensions of the ceramic sample.

This containment must be robust enough to prevent powder leakage while maintaining dimensional precision under extreme thermal and mechanical stress.

The "Coupling" Effect on LaFeO3

Synchronized Forces

The true value of the graphite mold lies in its ability to handle heat, electricity, and pressure simultaneously.

This allows for a unique process environment where thermal expansion and mechanical compression occur at the exact same moment.

Rapid Densification

This synchronization leads to rapid densification of the LaFeO3.

By applying heat and pressure together through the same medium, the process minimizes grain growth while maximizing structural integrity.

Understanding the Trade-offs

Carbon Diffusion Risks

While graphite is an excellent conductor, it is chemically reactive at high temperatures.

There is a risk of carbon atoms diffusing from the mold into the surface of the material being sintered.

For sensitive applications, the surface layer of the sintered sample may need to be removed to ensure the mechanical properties of the LaFeO3 are not compromised by carbon contamination.

Mechanical Limitations

Graphite is strong, but it is not indestructible.

While it can handle pressures up to 80 MPa in this context, pushing beyond these limits can lead to mold fracture.

Furthermore, graphite molds effectively degrade over time due to thermal cycling and mechanical wear, acting as a consumable rather than a permanent fixture.

Making the Right Choice for Your Goal

To maximize the effectiveness of graphite molds in your SPS process, consider your specific constraints:

- If your primary focus is Maximum Density: Ensure your mold design is rated to withstand the upper pressure limit (80 MPa) to maximize the mechanical force applied to the LaFeO3 powder.

- If your primary focus is Material Purity: Plan for post-processing steps to grind away potential carbon contamination on the surface layers of the sintered ceramic.

- If your primary focus is Process Speed: Utilize the high thermal conductivity of graphite to increase heating rates, but monitor the mold for thermal shock to prevent premature cracking.

The graphite mold is not a passive accessory; it is the active instrument that enables the rapid, high-quality synthesis of advanced ceramics.

Summary Table:

| Function | Role in SPS Process | Key Benefit for LaFeO3 |

|---|---|---|

| Resistive Heating | Converts electrical current to thermal energy (Joule heating) | Rapid and efficient heating adjacent to powder |

| Pressure Transmission | Transfers mechanical loads up to 80 MPa | High-density stabilization of ceramic structure |

| Geometric Containment | Defines final sample shape and dimensions | Precision forming under extreme thermal stress |

| Force Coupling | Synchronizes thermal, electrical, and mechanical forces | Maximizes structural integrity while minimizing grain growth |

Elevate Your Materials Synthesis with KINTEK Precision

Unlock the full potential of your Spark Plasma Sintering (SPS) applications. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Graphite, Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temperature solutions are fully customizable to meet the rigorous demands of LaFeO3 densification and advanced ceramic research.

Ready to optimize your sintering results?

Contact KINTEK today for expert guidance and custom lab solutions.

Visual Guide

References

- Pavel Ctibor, Libor Straka. Characterization of LaFeO3 Dielectric Ceramics Produced by Spark Plasma Sintering. DOI: 10.3390/ma17020287

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Spark Plasma Sintering SPS Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- How does the high-precision temperature control system of a sintering furnace influence nano-copper microstructure?

- What is the primary objective of using Hot Isostatic Pressing (HIP) for L-PBF Ti-6Al-4V? Maximize Component Integrity

- What are the benefits of the high vacuum environment in a vacuum hot pressing sintering furnace? Gain Maximum Density

- What is the core function of a vacuum hot press sintering furnace? Unlock High-Performance TiCN Composite Synthesis

- How does the mechanical pressure of a Vacuum Hot Press Furnace improve composite density? Elevate Performance Today

- Why is a Vacuum Hot Press Sintering (VHPS) furnace preferred for AlxCoCrFeNi high-entropy alloys? Achieve 99% Density

- What are the advantages of SPS over hot pressing for high-entropy alloys? Achieve Superior Density and Microstructure