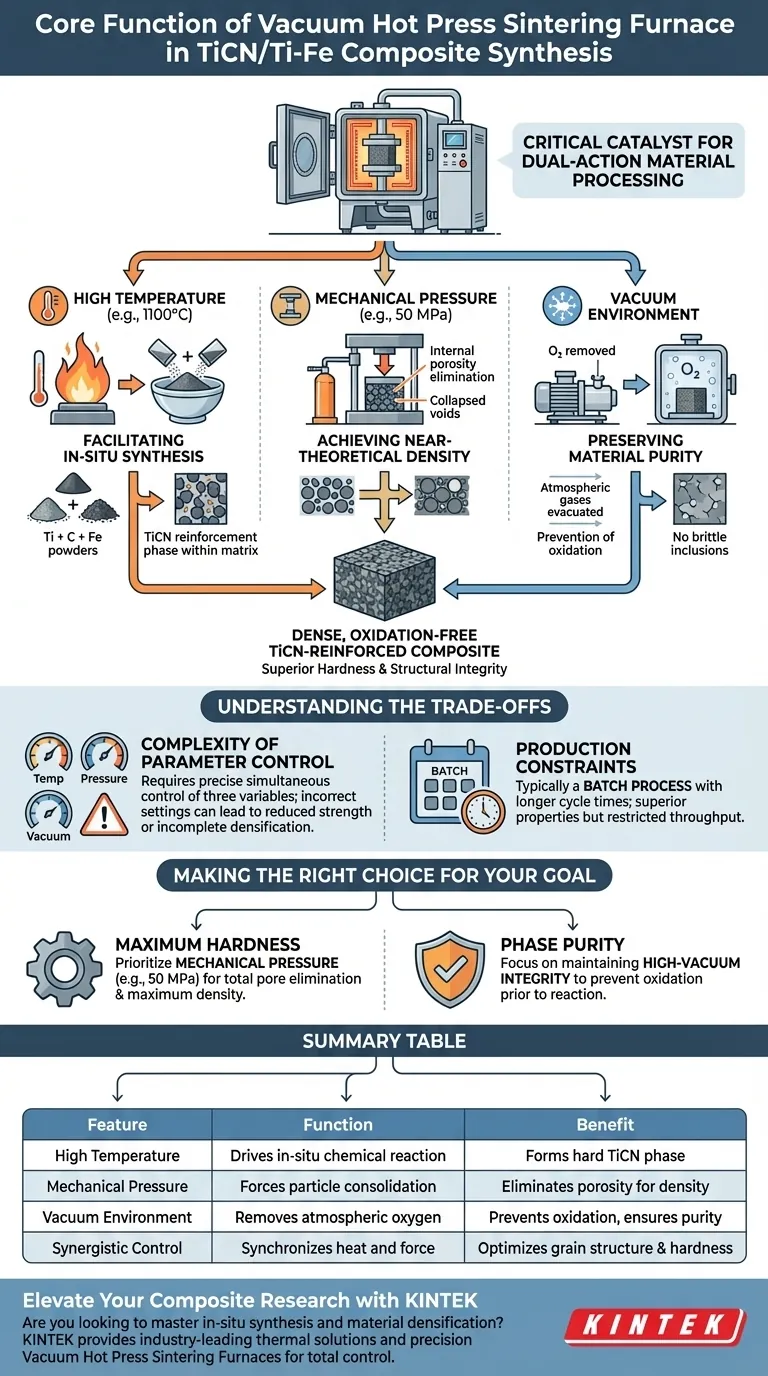

The vacuum hot press sintering furnace serves as the critical catalyst for dual-action material processing. It functions by simultaneously applying high temperature and mechanical pressure within a vacuum environment. This synergistic approach drives the in-situ chemical reaction to generate TiCN reinforcement particles while forcibly eliminating internal porosity, resulting in a dense, oxidation-free titanium-iron composite.

By integrating thermal energy, mechanical force, and environmental control, this equipment transforms raw powders into high-performance composites. It enables the simultaneous synthesis of the TiCN hard phase and the physical densification of the matrix, ensuring superior hardness and structural integrity.

The Mechanics of Synergistic Processing

Facilitating In-Situ Synthesis

The primary role of the furnace is to create the thermodynamic conditions necessary for a chemical reaction to occur inside the material.

By maintaining high temperatures (e.g., 1100°C), the furnace supplies the energy required for titanium, carbon, and the iron matrix to react. This generates the TiCN reinforcement phase directly within the matrix, rather than having it added externally.

Achieving Near-Theoretical Density

While the chemical reaction occurs, the furnace applies significant mechanical pressure (e.g., 50 MPa).

This pressure is critical for densification. It forces the solid particles together, collapsing internal voids and eliminating pores that naturally occur during sintering. The result is a composite material with high density and enhanced mechanical hardness.

Preserving Material Purity

The "vacuum" component of the furnace is essential for processing reactive metals like titanium.

By operating in a high-vacuum environment, the furnace removes oxygen and other atmospheric gases. This prevents the oxidation of the titanium and iron components. Without this vacuum, brittle oxide inclusions would form, severely degrading the material's strength and bonding capabilities.

Understanding the Trade-offs

Complexity of Parameter Control

The strength of vacuum hot pressing lies in its ability to control three variables—temperature, pressure, and vacuum—simultaneously. However, this creates a complex processing window.

If the temperature is too high without adequate pressure, grain growth may occur, reducing strength. Conversely, if the pressure is applied before the correct temperature is reached, the material may not deform plastically, leading to incomplete densification.

Production Constraints

Unlike continuous sintering methods, vacuum hot pressing is typically a batch process.

Because the materials must be sealed in a chamber, evacuated, heated under pressure, and then cooled, the cycle times are longer. This yields superior material properties but generally restricts throughput compared to pressureless sintering methods.

Making the Right Choice for Your Goal

To maximize the effectiveness of a vacuum hot press sintering furnace for TiCN composites, align your process parameters with your specific engineering targets:

- If your primary focus is Maximum Hardness: Prioritize the mechanical pressure settings (e.g., targeting 50 MPa) to ensure total pore elimination and maximum density.

- If your primary focus is Phase Purity: Focus on maintaining a high-vacuum integrity throughout the heating cycle to prevent oxidation of the titanium prior to the reaction.

The vacuum hot press furnace is not just a heating element; it is a precision tool that forces the convergence of chemistry and mechanics to forge advanced composite materials.

Summary Table:

| Feature | Function in TiCN Synthesis | Benefit to Material |

|---|---|---|

| High Temperature | Drives in-situ chemical reaction | Forms hard TiCN reinforcement phase |

| Mechanical Pressure | Forces particle consolidation | Eliminates porosity for near-theoretical density |

| Vacuum Environment | Removes atmospheric oxygen | Prevents oxidation and ensures material purity |

| Synergistic Control | Synchronizes heat and force | Optimizes grain structure and hardness |

Elevate Your Composite Research with KINTEK

Are you looking to master the complexities of in-situ synthesis and material densification? KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our precision Vacuum Hot Press Sintering Furnaces are designed to give you total control over temperature, pressure, and vacuum levels, ensuring your TiCN-reinforced composites achieve maximum hardness and structural integrity.

From Muffle and Tube furnaces to specialized Vacuum and CVD systems, we offer customizable high-temp lab equipment tailored to your unique engineering needs. Partner with KINTEK to transform your raw powders into high-performance materials.

Contact Our Experts Today to Discuss Your Custom Solution

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What specific issue does the vacuum environment within a Vacuum Hot Press furnace address? Stop A356/SiCp Oxidation

- What are the advantages of using a vacuum hot press? Achieve Superior Material Quality and Precision

- What role does a laboratory hydraulic press play in forming BCZT powder? Achieve Precise 10mm Green Compacts

- What are the advantages of benchtop SPS/FAST for titanium R&D? Accelerate Your Microstructural Engineering

- What is the core function of a vacuum hot press furnace? Achieve Near-Perfect Densification for Nano-Copper

- Why is high-strength graphite selected for vacuum hot pressing of thermoelectric alloys? High-Heat Stability Expert

- What are the primary functions of high-strength graphite molds? Optimize GNPs-Cu/Ti6Al4V Hot-Pressing Sintering

- What functions do graphite molds serve in the vacuum hot pressing of copper-carbon nanotube composites?