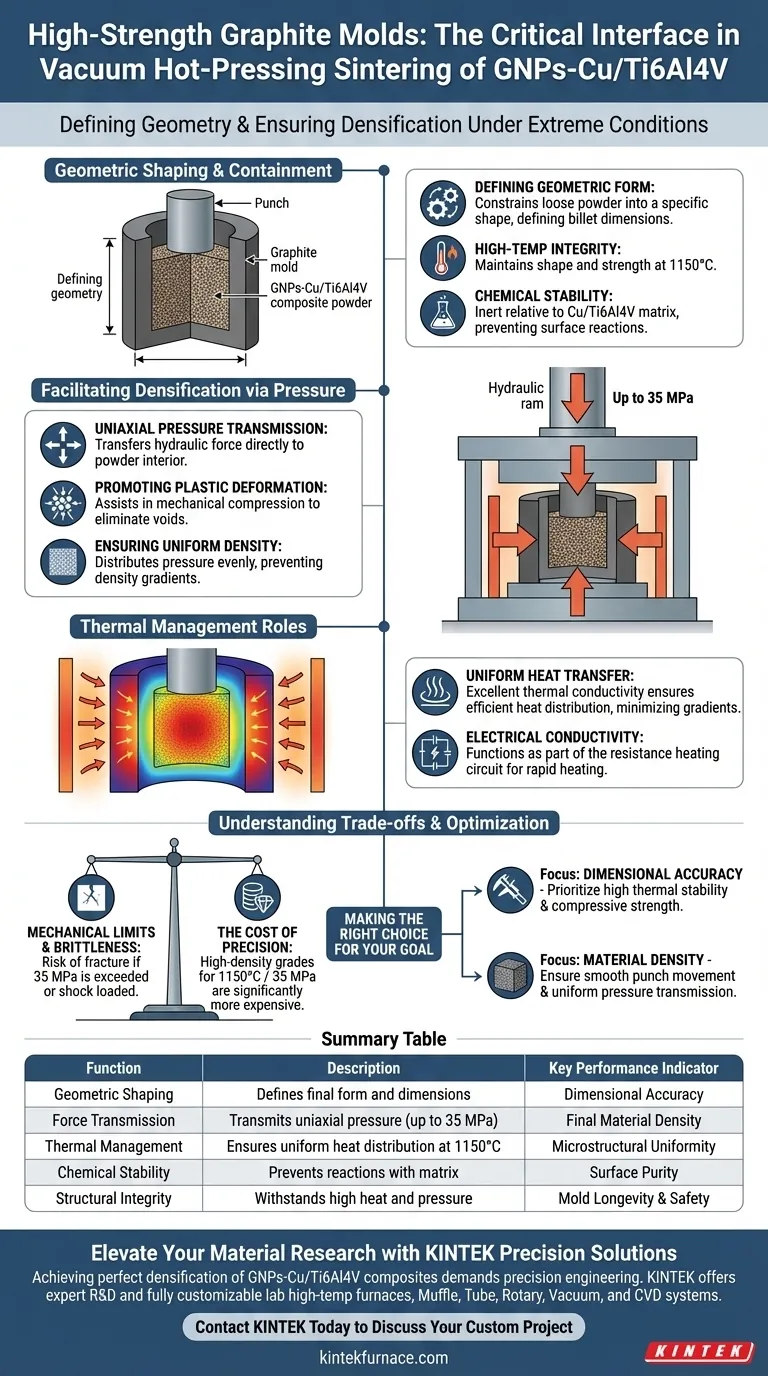

High-strength graphite molds serve as the critical interface between the vacuum hot-pressing equipment and the GNPs-Cu/Ti6Al4V composite powder. Their primary function is to act as a robust forming container that defines the geometry of the billet while withstanding extreme processing conditions, specifically uniaxial mechanical pressures up to 35 MPa and sintering temperatures of 1150°C.

Core Takeaway Beyond simple containment, these molds are active participants in the densification process. They function as a thermal and mechanical transmission medium, ensuring that heat and pressure are distributed uniformly to guarantee the density and dimensional accuracy of the final sintered body.

The Mechanics of Containment and Shaping

Defining Geometric Form

The most immediate function of the graphite mold is to serve as the vessel for the composite powder. It constrains the loose powder into a specific shape, defining the final dimensions of the composite billet.

High-Temperature Structural Integrity

For GNPs-Cu/Ti6Al4V composites, sintering occurs at approximately 1150°C. The graphite mold must possess exceptional thermal stability to maintain its shape and strength without softening or deforming at these elevated temperatures.

Chemical Stability

During the long hold times at high heat, the mold must remain chemically inert relative to the composite mixture. This stability prevents adverse chemical reactions between the mold walls and the Cu/Ti6Al4V matrix, ensuring the purity of the sample surface.

Facilitating Densification via Pressure

Uniaxial Pressure Transmission

The mold acts as a force transmission medium. It transfers the immense hydraulic force (up to 35 MPa) from the hot press ram directly to the powder interior.

Promoting Plastic Deformation

By effectively transmitting this external pressure, the mold assists in the plastic deformation of the powder particles. This mechanical compression is essential for eliminating voids and achieving a fully dense structure.

Ensuring Uniform Density

High-strength graphite is rigid enough to distribute pressure evenly across the sample. This prevents pressure gradients that could lead to areas of varying density or structural weakness within the final composite.

Thermal Management Roles

Uniform Heat Transfer

Graphite possesses excellent thermal conductivity. This allows the mold to transfer heat from the heating elements to the powder center efficiently, minimizing thermal gradients that could cause warping or uneven sintering.

Electrical Conductivity

In resistance heating environments, the mold often functions as part of the electrical circuit. Its electrical conductivity helps generate and conduct the necessary heat to reach sintering temperatures rapidly.

Understanding the Trade-offs

Mechanical Limits and Brittleness

While "high-strength" graphite is robust, it is a ceramic-like material and remains brittle compared to metals. Exceeding the rated pressure (e.g., going significantly beyond 35 MPa in this specific context) or subjecting the mold to shock loading can cause catastrophic fracture.

The Cost of Precision

High-strength, high-density graphite grades required for these specific parameters (1150°C / 35 MPa) are significantly more expensive than standard extruded graphite. Using a lower-grade graphite to save costs often results in mold deformation, resulting in poor dimensional accuracy of the final part.

Making the Right Choice for Your Goal

To optimize the sintering of GNPs-Cu/Ti6Al4V composites, select your mold grade based on your most critical outcome:

- If your primary focus is Dimensional Accuracy: Prioritize graphite with high thermal stability and high compressive strength to prevent mold wall deformation under the 35 MPa load.

- If your primary focus is Material Density: Ensure the mold design allows for smooth punch movement and uniform pressure transmission to maximize particle deformation.

Success in vacuum hot-pressing relies on viewing the mold not just as a container, but as a precision tool for thermal and mechanical transfer.

Summary Table:

| Function | Description | Key Performance Indicator |

|---|---|---|

| Geometric Shaping | Defines the final form and dimensions of the billet | Dimensional Accuracy |

| Force Transmission | Transmits uniaxial pressure (up to 35 MPa) to the powder | Final Material Density |

| Thermal Management | Ensures uniform heat distribution at 1150°C | Microstructural Uniformity |

| Chemical Stability | Prevents reactions between mold and Cu/Ti6Al4V matrix | Surface Purity |

| Structural Integrity | Withstands high heat and pressure without deformation | Mold Longevity & Safety |

Elevate Your Material Research with KINTEK Precision Solutions

Achieving the perfect densification of GNPs-Cu/Ti6Al4V composites requires more than just high temperatures—it demands precision engineering. At KINTEK, we understand that your mold and furnace performance are critical to your success.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique sintering and hot-pressing needs. Our equipment is designed to provide the thermal stability and pressure control necessary for your most demanding material innovations.

Ready to optimize your sintering process? Contact KINTEK Today to Discuss Your Custom Project

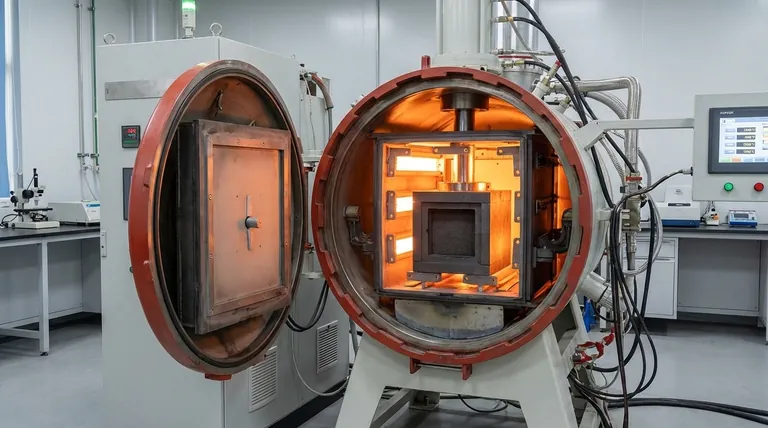

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the advantages of using WC-Co anvils in UHP-SPS? Unlock Extreme Sintering Pressures and Material Density

- What are the key components of a vacuum hot press? Master Temperature, Pressure, and Atmosphere Control

- How does hot pressing improve mechanical properties of materials? Achieve Superior Strength and Durability

- What is the application of hot press furnaces in ceramic processing? Achieve Superior Density and Strength

- What is the significant advantage of using a vacuum hot press furnace compared to pressureless sintering for preparing highly dense h-BN ceramics? Achieve Near-Theoretical Density with Mechanical Force

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- How does the heating mechanism of Spark Plasma Sintering (SPS) function? Enhance TiC/SiC Composite Fabrication

- What function does a vacuum hot press furnace serve in the densification of Nb-22.5Cr-5Si alloys? Achieve Full Density and Purity for Refractory Alloys