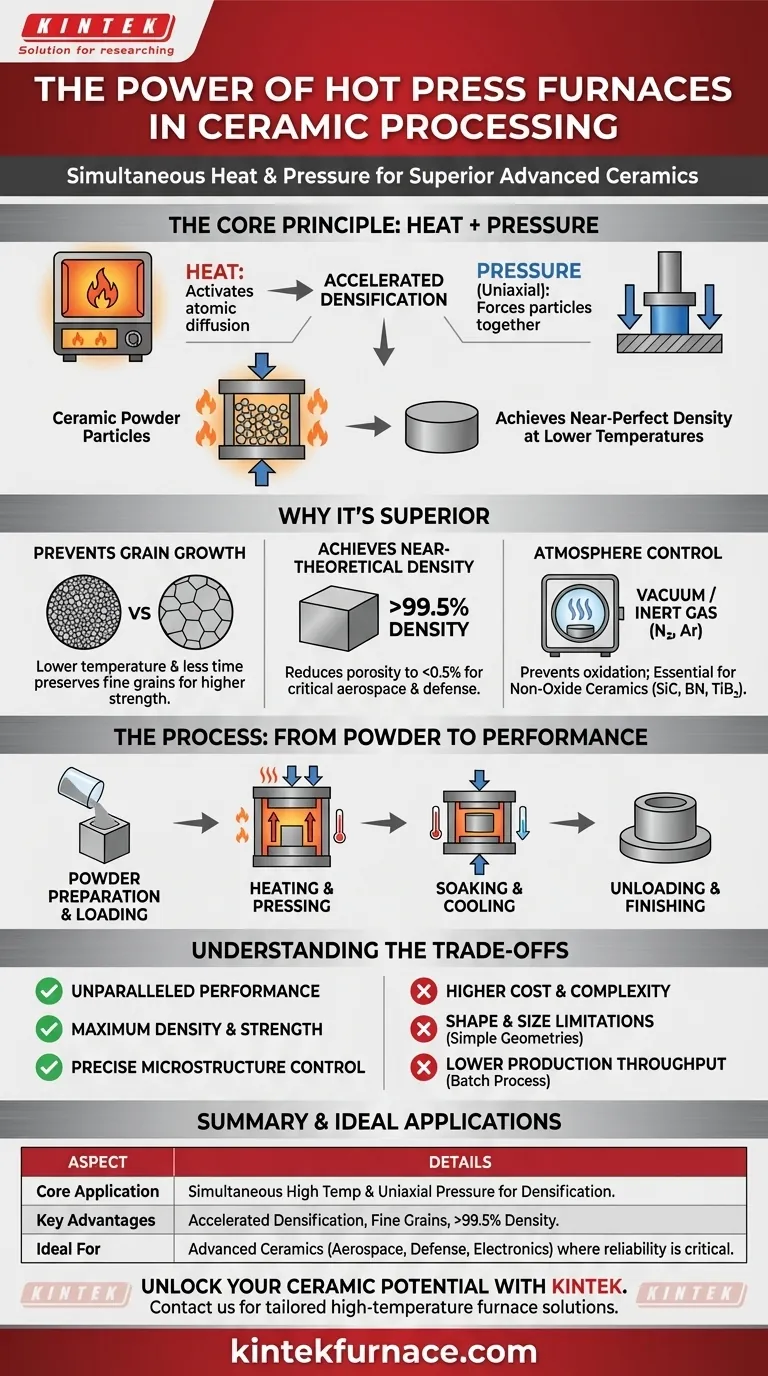

At its core, a hot press furnace is used in ceramic processing to simultaneously apply high temperature and immense pressure, forging powdered raw materials into exceptionally dense and strong solid components. This process, known as hot pressing or sintering under pressure, is critical for manufacturing advanced ceramics that possess properties unattainable through conventional heating methods alone.

The fundamental advantage of hot pressing is its ability to dramatically accelerate the densification of ceramic powders. By physically forcing particles together while heating them, it achieves near-perfect density at lower temperatures, which prevents the grain growth that weakens conventional ceramics.

The Core Principle: Overcoming Sintering Barriers

Traditional ceramic processing relies on sintering, where ceramic powders are heated in a furnace. The heat gives atoms the energy to diffuse across the boundaries of particles, causing them to fuse together and reduce the empty space (porosity) between them. Hot pressing enhances this fundamental process.

How It Works: Heat and Uniaxial Pressure

A hot press furnace contains a die, typically made of graphite, which holds the ceramic powder. Plungers, or rams, compress the powder along a single axis while the furnace heats the entire assembly. This combination of heat and uniaxial (single-direction) pressure is the defining characteristic of the process.

The Advantage: Accelerated Densification

The applied pressure dramatically increases the points of contact between ceramic particles. This provides shorter paths for atomic diffusion and physically forces material to fill the voids, leading to rapid and more complete densification compared to pressureless sintering.

Why Hot Pressing Creates Superior Ceramics

The true value of hot pressing is its ability to solve the inherent compromises of traditional, high-temperature sintering. It allows for precise control over the final microstructure of the ceramic, which directly dictates its performance.

Problem: Unwanted Grain Growth in Traditional Sintering

To achieve high density with heat alone, ceramics often require very high temperatures held for long periods. A major side effect is grain growth, where smaller crystal grains merge into larger ones. While the material gets denser, these large grains can act as weak points, reducing the final strength and fracture toughness.

Solution: Lower Temperatures and Finer Grains

By adding pressure, hot pressing achieves full density at significantly lower temperatures and in less time. This crucial difference prevents excessive grain growth. The resulting ceramic retains a fine-grained microstructure, which is a key factor in achieving superior mechanical properties like hardness and strength.

Solution: Achieving Near-Theoretical Density

For critical applications in aerospace, defense, or electronics, porosity is a fatal flaw. Voids act as stress concentrators and initiation points for cracks. Hot pressing can reduce porosity to less than 0.5%, achieving a density that is over 99.5% of the material's theoretical maximum.

Requirement: Atmosphere Control for Purity

Most hot press furnaces operate under a vacuum or a controlled inert atmosphere (like nitrogen or argon). This is essential for preventing oxidation or chemical reactions, especially when processing sensitive non-oxide ceramics such as silicon carbide (SiC), boron nitride (BN), or titanium diboride (TiB₂).

Understanding the Trade-offs

While hot pressing offers unparalleled performance, it is not the solution for every ceramic application. The process comes with specific limitations that make it a specialized, rather than a general-purpose, tool.

High Cost and Complexity

Hot press furnaces are significantly more complex and expensive to purchase and operate than conventional atmosphere or muffle furnaces. The need for robust pressure systems and vacuum-tight chambers adds to this cost.

Limitations on Shape and Size

The use of a die and uniaxial pressure inherently limits production to relatively simple shapes, such as discs, blocks, and cylinders. Creating complex, near-net-shape parts is generally not feasible with this method.

Lower Production Throughput

Hot pressing is a batch process. Each cycle of loading, heating, pressing, cooling, and unloading takes considerable time. This results in lower throughput compared to more continuous sintering methods, making it less suitable for high-volume, low-cost ceramic components.

Making the Right Choice for Your Goal

Selecting the right thermal processing method depends entirely on the required performance and economic constraints of your final product.

- If your primary focus is maximum performance and reliability: Hot pressing is the definitive choice for achieving the highest possible density, strength, and hardness, especially for critical components.

- If your material is a non-oxide ceramic sensitive to oxidation: The controlled atmosphere or vacuum environment of a hot press is non-negotiable for preserving material purity.

- If you need to produce complex shapes or high volumes at a lower cost: Traditional pressureless sintering in an atmosphere or muffle furnace is a more practical and economical approach.

Ultimately, hot pressing is the engineering tool for transforming ceramic powders into high-performance solids when material failure is not an option.

Summary Table:

| Aspect | Details |

|---|---|

| Core Application | Simultaneously applies high temperature and uniaxial pressure to ceramic powders for densification and strength enhancement. |

| Key Advantages | Accelerated densification, lower processing temperatures, prevention of grain growth, near-theoretical density (over 99.5%), and controlled microstructure. |

| Ideal For | Advanced ceramics in aerospace, defense, electronics, and other high-performance applications where material reliability is critical. |

| Limitations | High cost, shape and size constraints (e.g., simple discs or cylinders), lower production throughput, and complexity in operation. |

| Atmosphere Control | Operates under vacuum or inert gases (e.g., nitrogen, argon) to prevent oxidation, essential for non-oxide ceramics like SiC, BN, and TiB₂. |

Unlock the Full Potential of Your Ceramic Processing with KINTEK

Struggling to achieve the high density and superior strength required for your advanced ceramic components? KINTEK specializes in providing tailored high-temperature furnace solutions that address your unique challenges. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Hot Press Furnaces, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your specific experimental and production needs, whether you're in aerospace, electronics, or research.

Contact us today via our contact form to discuss how our advanced furnace technologies can enhance your ceramic processing efficiency and outcomes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is a hot press used for? Fabricate Dense, High-Performance Materials