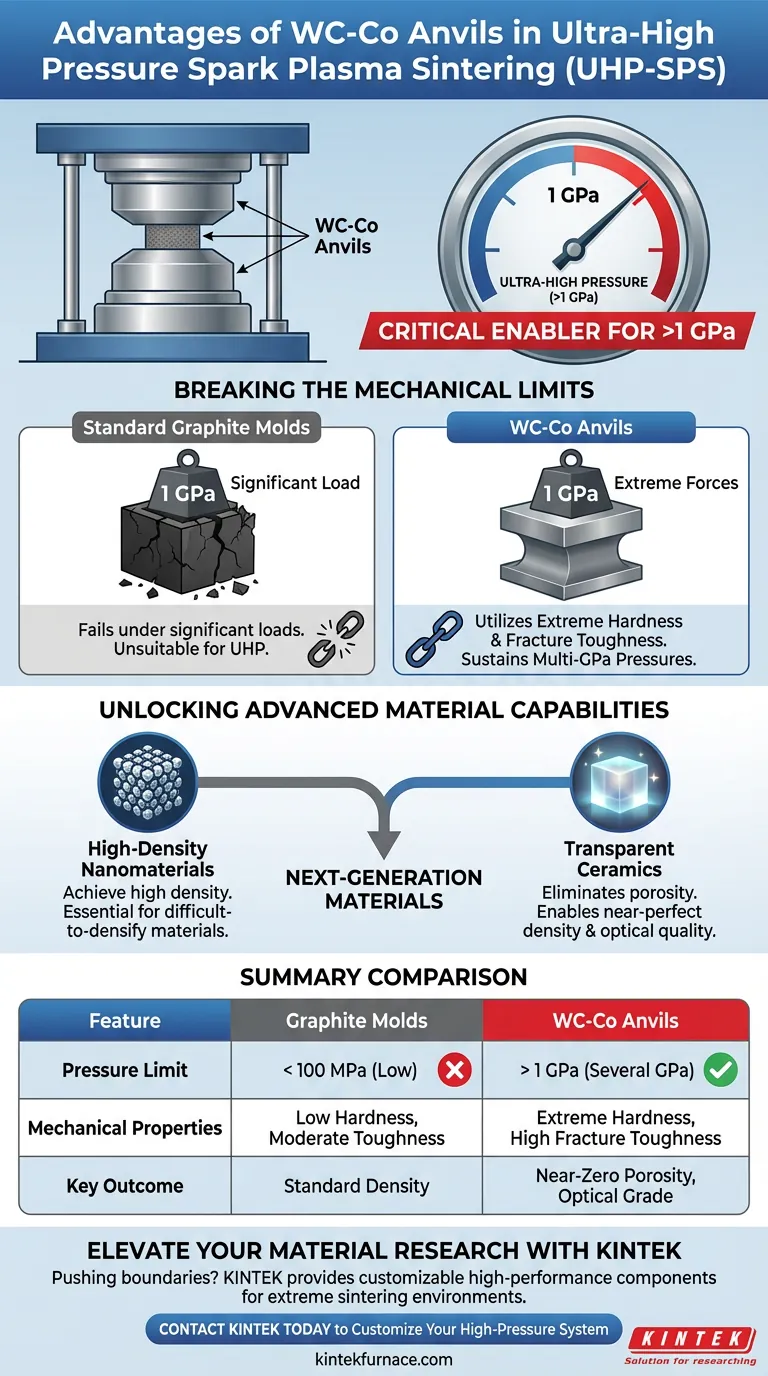

Tungsten Carbide-Cobalt (WC-Co) anvils are the critical enabler for operating in pressure ranges exceeding 1 GPa. In Ultra-High Pressure Spark Plasma Sintering (UHP-SPS) environments, standard graphite molds lack the necessary load-bearing capacity. WC-Co provides the structural integrity required to withstand these extreme forces without failure.

While traditional graphite molds fail under significant loads, WC-Co anvils utilize extreme hardness and fracture toughness to sustain pressures of several GPa, unlocking the ability to manufacture high-density nanomaterials and transparent ceramics.

Overcoming the Mechanical Limits of Sintering

Breaking the 1 GPa Barrier

Standard sintering operations often utilize graphite, but this material hits a hard performance ceiling.

Graphite simply lacks the load-bearing capacity required for Ultra-High Pressure (UHP) applications.

When your process requires static pressures exceeding 1 GPa, utilizing WC-Co is not just an advantage; it is a mechanical necessity.

Essential Material Properties

The effectiveness of WC-Co in these environments stems from two specific physical characteristics: extreme hardness and fracture toughness.

These properties allow the anvils to maintain their shape and structural integrity under loads of several GPa.

Without this combination of toughness and hardness, the anvil would likely deform or fracture during the sintering cycle.

Unlocking Advanced Material Capabilities

Fabrication of High-Density Nanomaterials

The primary advantage of sustaining such high pressures is the effect on the material being sintered.

WC-Co anvils allow for the application of sufficient force to achieve high density in nanomaterials.

This capability is essential for researchers and engineers working with materials that are difficult to densify using standard pressure ranges.

Producing Transparent Ceramics

Transparency in ceramics is strictly dependent on eliminating porosity and achieving near-perfect density.

The extreme pressures facilitated by WC-Co anvils are required to force materials into this void-free state.

Consequently, WC-Co is the enabling technology for the production of transparent ceramic components.

Understanding the Operational Constraints

The Load-Bearing Threshold

The decision to use WC-Co is defined by the limitations of the alternative: graphite.

Users must recognize that graphite is unsuitable for UHP-SPS because it cannot bear the required load.

Therefore, the "trade-off" is operational: to access the regime above 1 GPa, you are forced to abandon graphite in favor of the superior mechanical resilience of WC-Co.

Making the Right Choice for Your Goal

Selecting the correct anvil material is determined strictly by your target pressure and the microstructural requirements of your final product.

- If your primary focus is extreme pressure application: You must utilize WC-Co to ensure structural stability and safety at static pressures exceeding 1 GPa.

- If your primary focus is optical quality or density: Deploy WC-Co anvils to generate the force necessary to produce fully dense nanomaterials and transparent ceramics.

By replacing graphite with Tungsten Carbide-Cobalt, you bridge the gap between standard sintering and the creation of next-generation high-performance materials.

Summary Table:

| Feature | Graphite Molds | WC-Co Anvils |

|---|---|---|

| Pressure Limit | Typically < 100 MPa | Exceeds 1 GPa (Several GPa) |

| Hardness | Low | Extremely High |

| Fracture Toughness | Moderate/Low | High |

| Primary Application | Standard Sintering | UHP-SPS & Nanomaterials |

| Key Outcome | Standard Density | Near-Zero Porosity/Optical Grade |

Elevate Your Material Research with KINTEK

Are you pushing the boundaries of material science? KINTEK provides the high-performance components needed for extreme sintering environments. Backed by expert R&D and precision manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to your unique research specifications.

Don't let equipment limits hinder your innovation. Whether you are developing transparent ceramics or high-density nanomaterials, our technical team is ready to engineer a solution for you.

Contact KINTEK Today to Customize Your High-Pressure System

Visual Guide

References

- Alexander M. Laptev, Olivier Guillon. Tooling in Spark Plasma Sintering Technology: Design, Optimization, and Application. DOI: 10.1002/adem.202301391

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does hot-press sintering contribute to manufacturing high-density Ta-Al-C MAX phase ceramics? Optimize Consolidation

- What are the steps in the hot press sintering process? Achieve Superior Material Density and Performance

- How does the high vacuum environment provided by a vacuum hot press furnace influence the properties of Cu/rGO composites? Achieve Superior Composite Performance

- What is the effect of extended holding time during Vacuum Hot Pressing (VHP)? Enhance Al3Ti Phase Purity and Density

- What is the core function of a vacuum hot press sintering furnace? Unlock High-Performance TiCN Composite Synthesis

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What types of materials can be processed using vacuum hot press furnaces? Ideal for Advanced Ceramics and Metals

- What role does a Spark Plasma Sintering (SPS) system play in the preparation of Al0.3CoCrFeNiMo0.75 bulk materials?