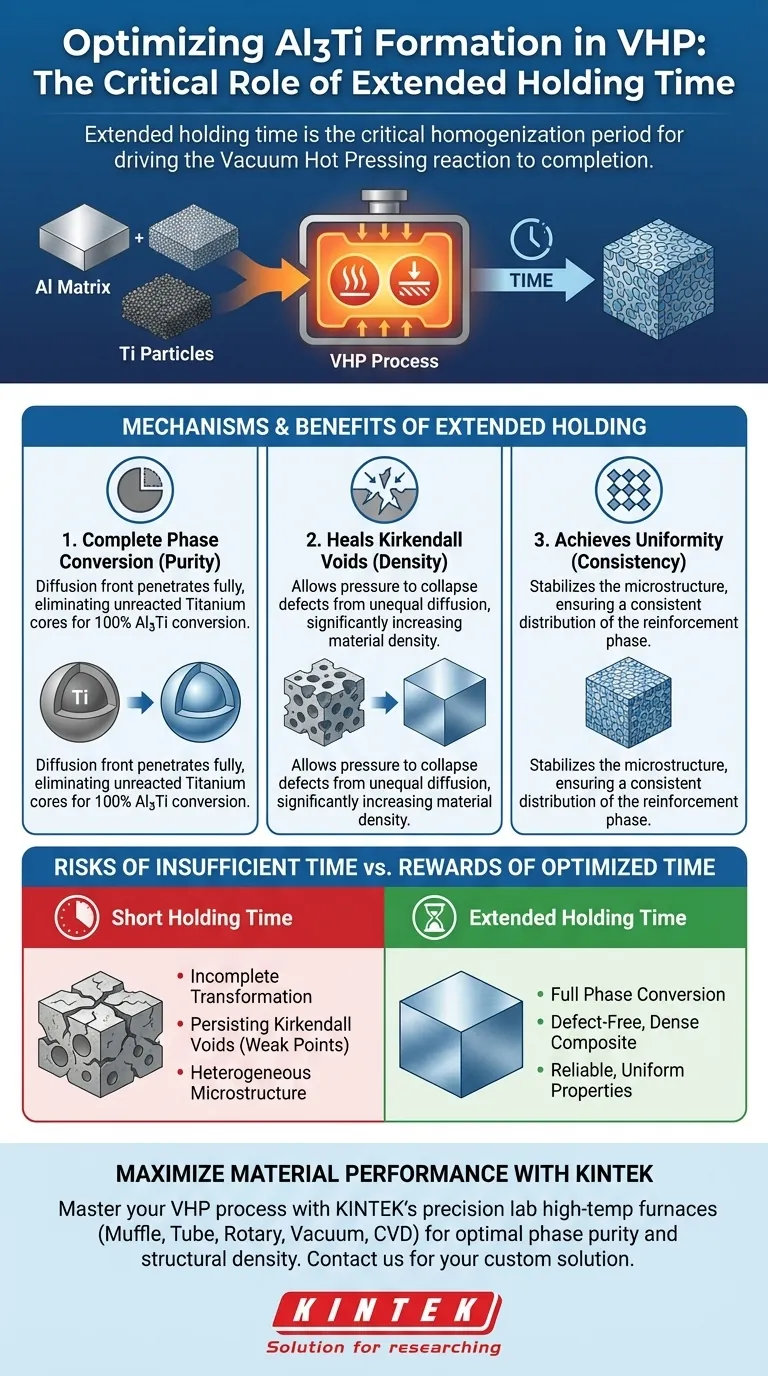

Extended holding time acts as the critical homogenization period in the Vacuum Hot Pressing (VHP) process. By maintaining the reaction temperature for a prolonged duration, you allow sufficient time for atomic interdiffusion between Aluminum and Titanium. This directly results in the elimination of unreacted Titanium cores, the creation of a uniform Al3Ti phase, and the healing of diffusion-induced defects known as Kirkendall voids.

While temperature provides the energy to initiate the reaction, holding time is what drives it to completion. Extending this duration is essential for ensuring a pure reinforcement phase free of residual Titanium and structural porosity.

Mechanisms of Phase Formation

To understand why holding time dictates the quality of the Al3Ti phase, we must look at the atomic behavior during the soak period.

Facilitating Atomic Interdiffusion

At the set reaction temperature, the formation of the reinforcement phase is a time-dependent diffusion process.

Holding the heat allows Aluminum and Titanium atoms to migrate across boundary layers. Without this sustained thermal exposure, the interaction between the metals remains superficial.

Eliminating Unreacted Cores

One of the primary goals of VHP is complete conversion. Short holding times often leave the centers of Titanium particles untouched.

Extending the holding time ensures the diffusion front penetrates fully into the Titanium particles. This effectively removes residual metallic Titanium, converting the particle cores entirely into the desired intermetallic Al3Ti phase.

Structural Integrity and Defects

Beyond chemical composition, the physical structure of the composite is heavily influenced by how long the material is held at pressure and temperature.

Achieving Phase Uniformity

A consistent microstructure requires a complete reaction throughout the entire matrix.

Extended holding time allows the newly formed Al3Ti phase to stabilize. This results in a uniform distribution of the reinforcement phase, avoiding clusters of unreacted material or gradients in composition.

Healing Kirkendall Voids

The diffusion process naturally creates defects known as Kirkendall voids, which occur due to the unequal diffusion rates of Aluminum and Titanium.

Extending the holding time is the primary method for remedying this. It allows the VHP process to apply heat and pressure long enough to collapse these voids, resulting in a denser and more structurally sound final composite.

The Risks of Insufficient Time

When optimizing a manufacturing cycle, it is tempting to reduce cycle times. However, the reference highlights specific risks associated with cutting the holding stage short.

Persisting Structural Weaknesses

If the holding time is curtailed, the mechanisms that heal diffusion defects are halted prematurely.

This leaves Kirkendall voids intact within the material matrix. These voids act as stress concentrators, significantly reducing the mechanical integrity of the final part.

Incomplete Phase Transformation

Speeding up the process risks leaving a heterogeneous microstructure.

Without adequate time, the composite remains a mixture of reacted interface layers and unreacted cores. This prevents the material from achieving the uniform properties expected of a fully formed Al3Ti reinforced composite.

Making the Right Choice for Your Goal

Optimizing your VHP profile requires prioritizing the specific material properties you need.

- If your primary focus is Phase Purity: Extend the holding time to ensure the diffusion front reaches the center of all Titanium particles, eliminating unreacted cores.

- If your primary focus is Material Density: Prioritize a longer hold to allow sufficient time for the pressure to collapse and heal Kirkendall voids generated during the reaction.

Success in VHP relies on treating time as an active variable that heals defects and finalizes the material structure.

Summary Table:

| Effect of Extended Holding Time | Impact on Al3Ti Phase & Composite Quality |

|---|---|

| Atomic Interdiffusion | Facilitates complete migration of Al and Ti atoms across boundary layers. |

| Phase Conversion | Eliminates unreacted Titanium cores, ensuring 100% conversion to Al3Ti. |

| Microstructure | Promotes a uniform phase distribution throughout the entire material matrix. |

| Defect Management | Collapses and heals Kirkendall voids for superior material density. |

| Mechanical Integrity | Reduces stress concentrators by removing structural porosity and voids. |

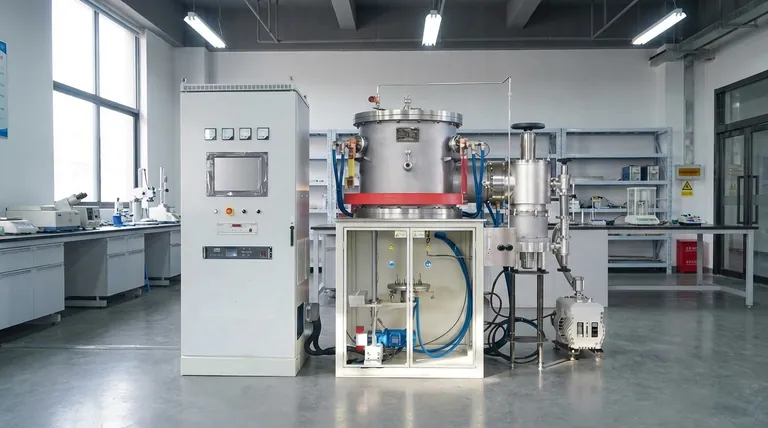

Maximize Your Material Performance with KINTEK

Achieving the perfect balance of temperature, pressure, and holding time is essential for high-quality Al3Ti reinforcement. At KINTEK, we provide the precision equipment necessary to master the Vacuum Hot Pressing process.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all fully customizable to meet your unique material science needs. Whether you are aiming for complete phase purity or maximum structural density, our systems provide the stability and control required for excellence.

Ready to optimize your VHP process? Contact us today to find your custom solution!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a vacuum hot-pressing furnace essential for graphite flake/Al composites? Achieving High Density & Performance

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- Why are graphite molds critical for Cu/rGO vacuum hot pressing? Enhance Precision and Densification

- Why is a Vacuum Hot Press (VHP) furnace preferred over stir casting? Achieve Near-Theoretical Density for Composites

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- Why are graphite molds necessary during the hot pressing sintering process of Fe-Cu-Ni-Sn-VN? Essential Sintering Tools

- What are the advantages of using a HIP sintering system over conventional sintering for Bismuth Telluride composites?

- How does a vacuum hot press furnace improve Ti2AlN ceramics? Achieve 4.15 g/cm³ Density and Superior Strength