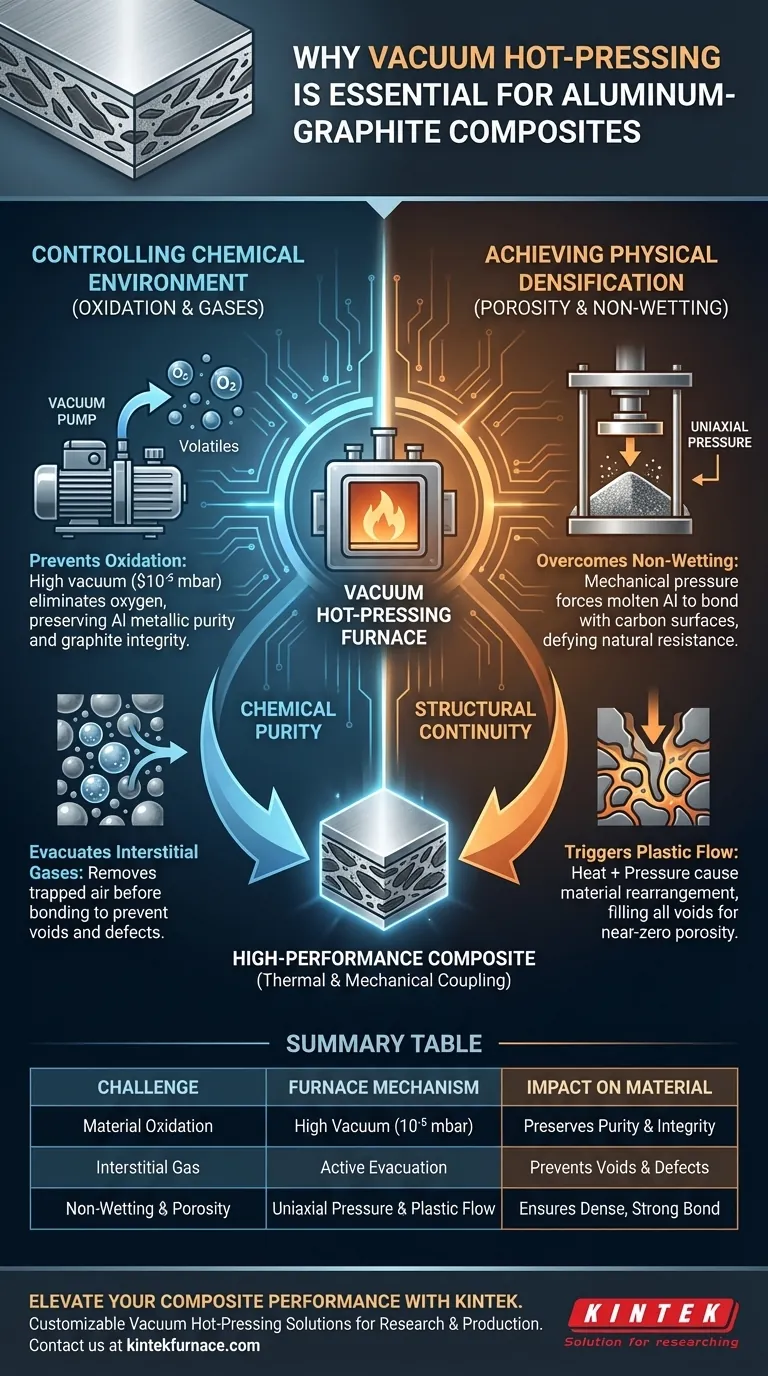

The vacuum hot-pressing furnace is essential because it simultaneously solves the two biggest challenges in composite fabrication: oxidation and porosity. By creating a high-vacuum environment, it prevents the graphite and aluminum from degrading due to oxygen exposure. Concurrently, the application of high mechanical pressure forces the aluminum into the microscopic gaps between graphite flakes, overcoming natural resistance to create a dense, high-performance material.

Core Insight: The success of aluminum-graphite composites relies on thermal-mechanical coupling. The vacuum ensures chemical purity by removing gases, while the pressure overcomes the physical "non-wetting" barrier between carbon and aluminum to ensure structural continuity.

Controlling the Chemical Environment

Preventing Material Oxidation

The most immediate function of the furnace is the protection of the raw materials. Aluminum powder is highly reactive and readily forms an oxide film at high temperatures, which acts as a thermal barrier.

Simultaneously, graphite flakes can degrade if exposed to oxygen during the heating phase. The vacuum environment (often as high as $10^{-5}$ mbar) eliminates oxygen, preserving the metallic purity of the aluminum and the structural integrity of the graphite.

Evacuation of Interstitial Gases

Before the material creates a solid bond, the powder mixture contains trapped air and volatiles in the spaces between particles.

The vacuum actively evacuates these gases from the interstitial spaces. If these gases were not removed prior to densification, they would remain trapped inside the final composite, leading to voids, defects, and significantly weaker interfacial bonding.

Achieving Physical Densification

Overcoming Non-Wetting Phenomena

A major challenge in pairing aluminum with carbon (graphite or nanotubes) is that they exhibit "non-wetting" behavior; essentially, molten aluminum does not naturally flow onto or stick to carbon surfaces.

Pressureless sintering often fails because the metal refuses to coat the graphite. The uniaxial pressure applied by the furnace acts as a mechanical force multiplier, physically driving the aluminum matrix to bond tightly with the graphite reinforcement despite this natural resistance.

Mechanisms of Plastic Flow

To achieve maximum density, the material must undergo physical rearrangement.

The combination of heat and pressure triggers plastic flow and creep mechanisms. This forces the aluminum into every available void and gap between the graphite flakes, resulting in a composite with near-zero porosity and superior thermophysical properties.

Critical Considerations and Trade-offs

The Balance of Pressure and Temperature

While high pressure is beneficial, it must be carefully calibrated. Excessive pressure at extreme temperatures can potentially damage delicate graphite structures or squeeze out the matrix excessively. The process requires precise control to achieve density without degrading the reinforcement architecture.

Complexity of Batch Processing

Unlike continuous casting methods, vacuum hot-pressing is inherently a batch process. It yields high-quality results but imposes constraints on production speed and part geometry. It is optimized for performance over volume, making it ideal for critical aerospace or automotive components where material failure is not an option.

Making the Right Choice for Your Goal

When configuring your vacuum hot-pressing process, align your parameters with your specific performance targets:

- If your primary focus is Thermal Conductivity: Prioritize the vacuum level to ensure the complete removal of oxide films, as these interfaces act as bottlenecks for heat transfer.

- If your primary focus is Mechanical Strength: Prioritize the pressure application profile to maximize plastic flow and eliminate even microscopic pores that could serve as crack initiation sites.

The vacuum hot-pressing furnace is not just a heating device; it is a precision tool that forces two dissimilar materials to act as a unified, high-performance solid.

Summary Table:

| Challenge in Composite Fabrication | Furnace Mechanism | Impact on Final Material |

|---|---|---|

| Material Oxidation | High Vacuum Environment ($10^{-5}$ mbar) | Preserves metallic purity and graphite integrity |

| Interstitial Gas Trapping | Active Gas Evacuation | Prevents internal voids and interfacial defects |

| Non-Wetting Behavior | Uniaxial Mechanical Pressure | Forces bonding between aluminum and carbon surfaces |

| High Porosity | Thermal-Mechanical Plastic Flow | Ensures near-zero porosity and structural continuity |

Elevate Your Composite Material Performance with KINTEK

Are you struggling with oxidation or porosity in your advanced material fabrication? KINTEK provides industry-leading thermal solutions designed to overcome the toughest material science challenges.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, including specialized Vacuum Hot-Pressing Furnaces. Our equipment is fully customizable to your unique research or production needs, ensuring you achieve the precise thermal-mechanical coupling required for high-performance composites.

Ready to optimize your densification process? Contact KINTEK today to consult with our technical team and discover how our advanced furnace technology can bring your material innovations to life.

Visual Guide

References

- Hongwei Shi, Zhendong Sun. FINITE ELEMENT SIMULATION OF THERMAL PROPERTIES OF COATED GRAPHITE FLAKE/ALUMINUM MATRIX COMPOSITES. DOI: 10.17222/mit.2025.1380

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is Vacuum Hot Press equipment considered a cornerstone of modern manufacturing? Unlock Superior Material Density and Purity

- What functions does a graphite mold perform? Unlock Superior Densification in Vacuum Hot Pressing

- Can you use a heat press for laminating? A Practical Guide for DIY and Crafting

- What safety features are incorporated in vacuum hot press furnaces? Ensure Operator and Equipment Protection

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the function of a vacuum hot pressing furnace? Precision Diffusion Bonding for 321H Stainless Steel

- What are the advantages of using a Spark Plasma Sintering (SPS) system for UHTCs? Master Rapid Densification

- Why is a high vacuum environment essential during hot press sintering? Achieve High-Strength Aluminum Composites