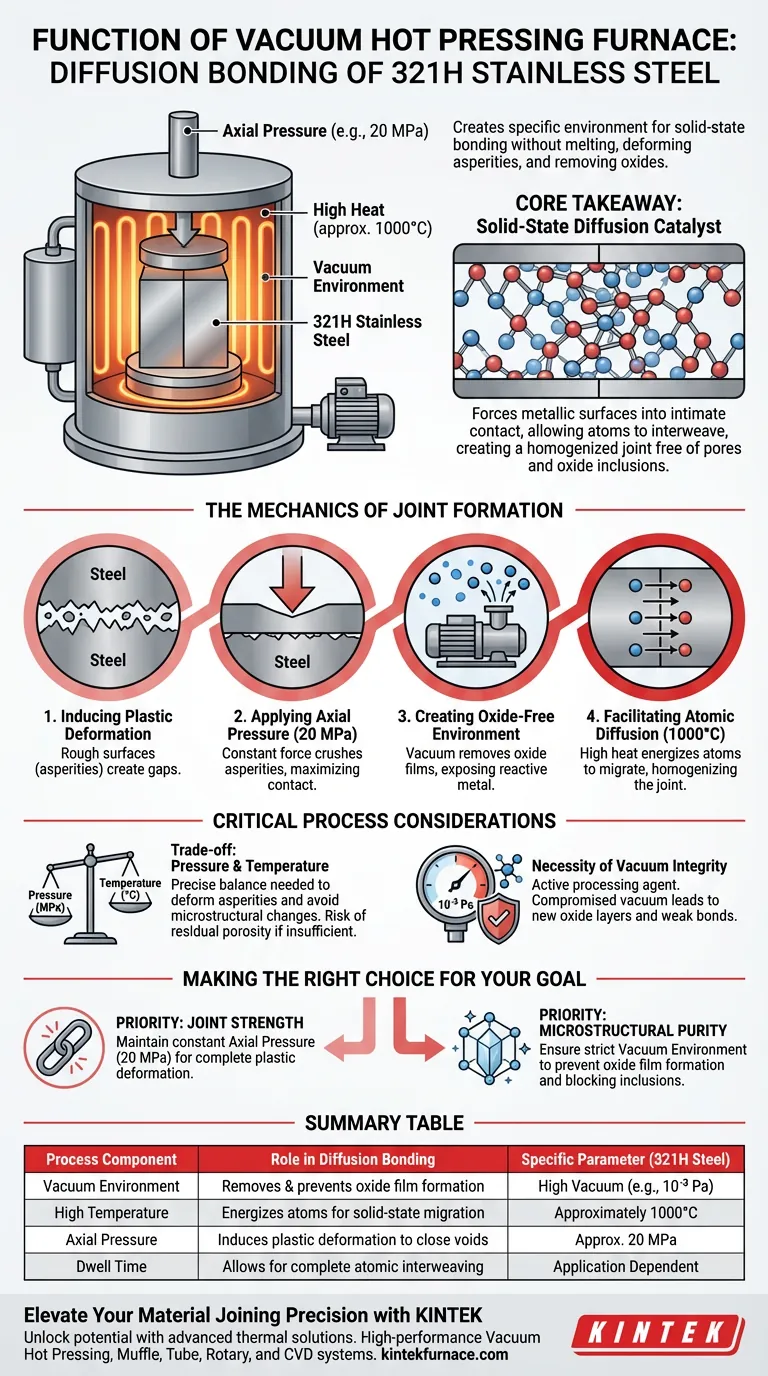

The primary function of a vacuum hot pressing furnace is to create a specific environment that enables the solid-state bonding of 321H stainless steel without melting the material. By simultaneously applying axial pressure (e.g., 20 MPa), high heat (approximately 1000°C), and a vacuum, the furnace mechanically deforms microscopic surface roughness and removes oxide barriers to allow for atomic diffusion.

Core Takeaway The furnace acts as a catalyst for solid-state diffusion, forcing metallic surfaces into such intimate contact that atoms interweave across the interface. It eliminates the need for brazing fillers or melting, resulting in a homogenized joint free of pores and oxide inclusions.

The Mechanics of Joint Formation

To understand the furnace's role, one must look beyond simple heating. The equipment orchestrates three simultaneous physical processes required to bond 321H stainless steel.

inducing Plastic Deformation

On a microscopic level, even polished steel surfaces are rough, consisting of peaks and valleys known as asperities. If you simply place two pieces of steel together, they only touch at these peaks, leaving gaps (voids) in between.

Applying Axial Pressure

The furnace applies a constant mechanical force, specifically around 20 MPa for this application. At elevated temperatures, this pressure crushes the asperities, inducing plastic deformation that flattens the surface peaks and maximizes the contact area between the mating surfaces.

Creating an Oxide-Free Environment

Stainless steel naturally forms oxide films that inhibit bonding. The furnace’s vacuum system removes existing surface oxide films and prevents new oxidation during the heating cycle. This exposes the fresh, reactive base metal, which is a prerequisite for atoms to cross the interface.

Facilitating Atomic Diffusion

Once the surfaces are in intimate contact and free of oxides, the high temperature (approx. 1000°C) energizes the atoms. The furnace maintains this environment to allow solid-state diffusion, where atoms migrate across the contact boundary. This process fills remaining microscopic voids and homogenizes the joint, effectively turning two distinct pieces into a single solid unit.

Critical Process Considerations

While the vacuum hot pressing furnace is a powerful tool, understanding its operational constraints is vital for joint integrity.

The Trade-off Between Pressure and Temperature

The process relies on a precise balance. Insufficient pressure or temperature will fail to fully deform the surface asperities, resulting in residual porosity at the joint interface. Conversely, excessive parameters could alter the microstructure of the 321H steel undesirably.

The Necessity of Vacuum Integrity

The vacuum is not merely for cleanliness; it is an active processing agent. If the vacuum level is compromised (e.g., failing to reach ranges like $10^{-3}$ Pa), residual gases can form new oxide layers. These layers act as blocking barriers to diffusion, rendering the mechanical pressure ineffective and leading to a weak bond.

Making the Right Choice for Your Goal

When configuring a vacuum hot pressing cycle for 321H stainless steel, align your parameters with your specific metallurgical objectives:

- If your primary focus is Joint Strength: Prioritize maintaining constant axial pressure (20 MPa) throughout the high-temperature dwell time to ensure complete plastic deformation of surface asperities.

- If your primary focus is Microstructural Purity: Ensure the vacuum system creates a strictly controlled environment to strip oxide films, preventing inclusions that effectively block atomic interweaving.

Ultimately, the furnace functions not just to join materials, but to eliminate the physical and chemical barriers that prevent them from becoming one.

Summary Table:

| Process Component | Role in Diffusion Bonding | Specific Parameter (321H Steel) |

|---|---|---|

| Vacuum Environment | Removes & prevents oxide film formation | High Vacuum (e.g., 10⁻³ Pa) |

| High Temperature | Energizes atoms for solid-state migration | Approximately 1000°C |

| Axial Pressure | Induces plastic deformation to close voids | Approx. 20 MPa |

| Dwell Time | Allows for complete atomic interweaving | Application Dependent |

Elevate Your Material Joining Precision with KINTEK

Unlock the full potential of your diffusion bonding projects with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Vacuum Hot Pressing, Muffle, Tube, Rotary, and CVD systems—all fully customizable to meet your unique metallurgical needs.

Whether you are bonding 321H stainless steel or developing next-generation alloys, our furnaces ensure the vacuum integrity and pressure precision required for superior joint strength.

Ready to optimize your lab's high-temperature processing? Contact us today to consult with our technical specialists!

Visual Guide

References

- Isac Lazar, Filip Lenrick. Diffusion Bonding 321-Grade Stainless Steel: Failure and Multimodal Characterization. DOI: 10.1093/mam/ozae019

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does the vacuum environment provided by a vacuum hot press furnace safeguard the performance of Fe-Cu-Ni-Sn-VN composites? Achieve Superior Densification and Wear Resistance

- How does the mechanical pressure of a Vacuum Hot Press Furnace improve composite density? Elevate Performance Today

- What are the key components of a vacuum hot press? Master Temperature, Pressure, and Atmosphere Control

- In which industries is the vacuum press commonly used? Essential for Aerospace, Medical, and Electronics

- What is the maximum working temperature of a vacuum hot press furnace? Achieve Precise High-Temp Processing

- What is a vacuum press used for? Achieve Flawless Bonding and Material Transformation

- What is the core function of a vacuum hot press sintering furnace in the preparation of high-density RuTi alloys? Achieve Maximum Density and Purity

- Why is a vacuum environment important in hot pressing? Essential for Purity and High-Density Materials