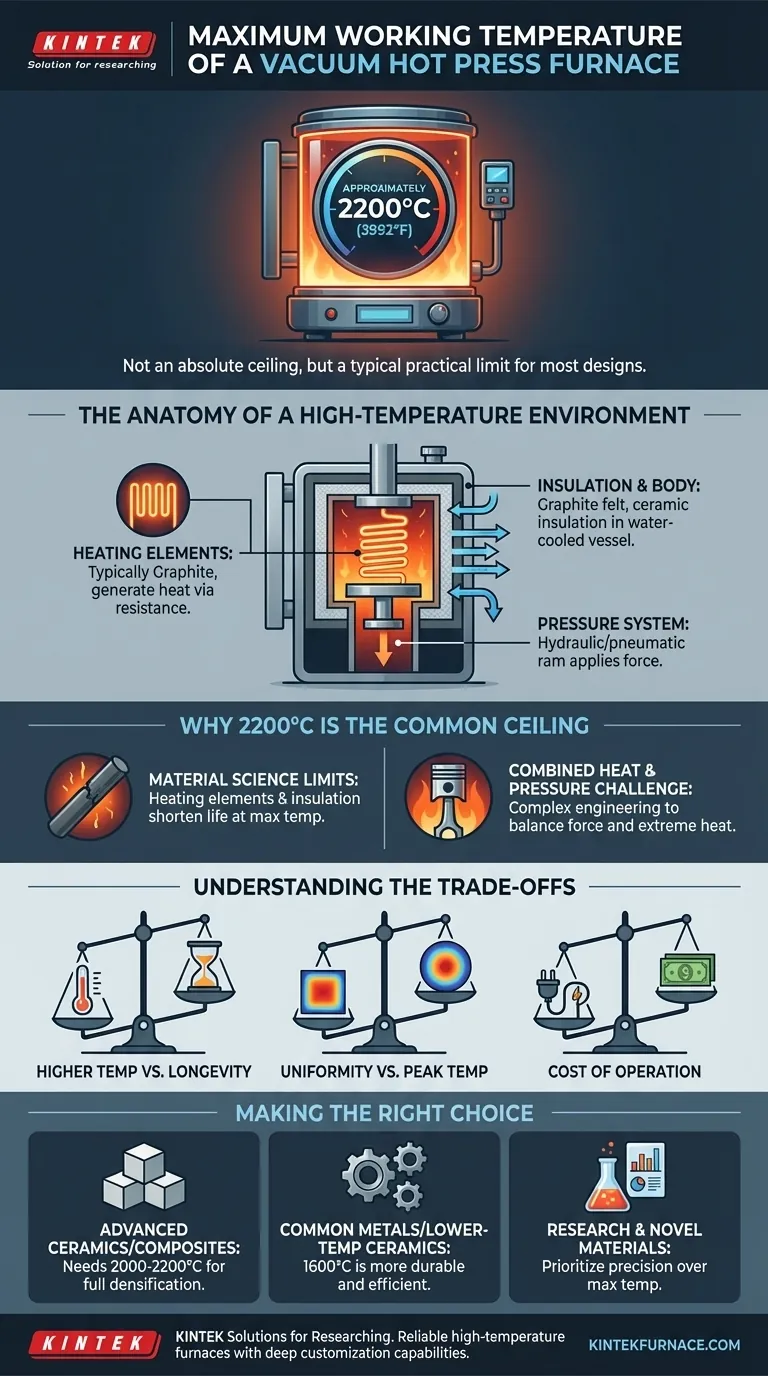

While figures can vary by design, the typical maximum working temperature for a vacuum hot press furnace is approximately 2200°C (3992°F). This capability allows it to process a wide range of advanced materials, but this number is not an absolute ceiling for all vacuum furnace technology. The true limit is dictated by the specific materials and engineering principles used in its construction.

The question isn't just about the highest possible temperature. The real issue is understanding how the furnace's components—heating elements, insulation, and pressure system—interact to create a stable, repeatable environment for your specific material processing needs.

The Anatomy of a High-Temperature Environment

A vacuum hot press furnace is an advanced system designed to apply both extreme heat and mechanical pressure in a controlled, oxygen-free environment. Each core component plays a critical role in defining its operational limits.

The Heart of the Furnace: Heating Elements

The maximum temperature is primarily determined by the material used for the heating elements. These components generate the heat through electrical resistance.

Most high-temperature hot press furnaces use graphite heating elements, which are cost-effective and can reliably reach temperatures around 2200°C before sublimation becomes a significant issue. For even higher temperatures, more exotic and expensive materials like tungsten may be used in specialized furnace designs.

Containing the Heat: Insulation and Furnace Body

Generating heat is only half the battle; containing it is equally important. The hot zone is surrounded by a heat preservation system, typically made of graphite felt or other ceramic-based insulation.

This insulation minimizes heat loss and protects the furnace's main body, which is usually a water-cooled, double-walled stainless steel vessel. The effectiveness of this insulation and the capacity of the water-cooling system are crucial for structural integrity and safety.

The 'Press' in Hot Press: The Pressure System

What distinguishes a hot press furnace is its ability to apply force, usually via a hydraulic or pneumatic ram. This system is used to densify materials during sintering.

This adds a significant engineering challenge. The pressure-applying components must be robust and precisely aligned while also being protected from the extreme temperatures of the hot zone, a task managed by sophisticated design and dedicated cooling circuits.

Why 2200°C is the Common Ceiling

While some specialized vacuum furnaces (without a press) can reach 2600°C or higher, the 2200°C figure is a common practical limit for hot press systems for two key reasons.

Material Science Limitations

The materials used for heating elements and insulation have practical operating limits. While they can survive spikes to higher temperatures, continuous operation near their maximum shortens their lifespan dramatically. Graphite, the industry standard, performs optimally up to the 2200°C range in a vacuum.

The Challenge of Combined Heat and Pressure

Integrating a high-force mechanical press into a high-temperature vacuum environment is incredibly complex. The thermal expansion of components, the need to protect seals, and the risk of heat transfer to the hydraulic system all create engineering constraints that make pushing beyond 2200°C prohibitively expensive and complex for most applications.

Understanding the Trade-offs

Simply looking for the highest temperature rating can be misleading. A true technical evaluation involves balancing competing factors.

Higher Temperature vs. System Longevity

Operating a furnace consistently at its absolute maximum temperature will significantly accelerate the degradation of critical components like heating elements and insulation. This leads to more frequent maintenance, costly downtime, and lower overall reliability.

Uniformity vs. Peak Temperature

For material processing, temperature uniformity across the workpiece is often far more important than the peak temperature reached. A furnace that can hold a stable and uniform 2000°C is vastly superior to one that can hit 2200°C in one spot but has significant cold spots elsewhere.

Cost of Operation

Reaching and maintaining higher temperatures requires exponentially more electrical power. It also places a greater load on the vacuum and water-cooling systems, further increasing operational and maintenance costs.

Making the Right Choice for Your Application

Choosing a furnace requires matching its capabilities to your specific process goals.

- If your primary focus is processing advanced ceramics or composites (e.g., SiC, B4C): You will need a furnace rated for the 2000°C to 2200°C range to achieve full and uniform densification.

- If your primary focus is sintering common metals or lower-temperature ceramics: A furnace with a lower maximum temperature (e.g., 1600°C) will be more durable, energy-efficient, and cost-effective for your needs.

- If your primary focus is research with novel materials: Prioritize a system with precise, programmable control over temperature, pressure, and atmosphere over one with the absolute highest temperature ceiling.

Ultimately, the ideal furnace is not the one with the highest number, but the one that provides the most stable and repeatable conditions for your specific process.

Summary Table:

| Aspect | Details |

|---|---|

| Typical Max Temperature | 2200°C (3992°F) |

| Key Components | Heating elements (e.g., graphite), insulation, pressure system |

| Common Applications | Advanced ceramics, composites, metals sintering |

| Key Considerations | Temperature uniformity, system longevity, cost of operation |

Need a reliable high-temperature furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for stable, repeatable material processing. Contact us today to discuss how our furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy