In hot pressing, a vacuum is not merely an optional feature; it is a fundamental process condition. The primary purpose of creating this vacuum is to prevent the high-temperature material from reacting with atmospheric gases, chiefly oxygen. This protection is critical for preventing oxidation and contamination, ensuring the final component maintains its intrinsic material properties and achieves superior densification.

A vacuum environment fundamentally alters the conditions of material consolidation. It moves beyond simply preventing contamination and actively enhances the physical process of densification, enabling the fabrication of high-purity, high-density components that are often impossible to produce in an ambient atmosphere.

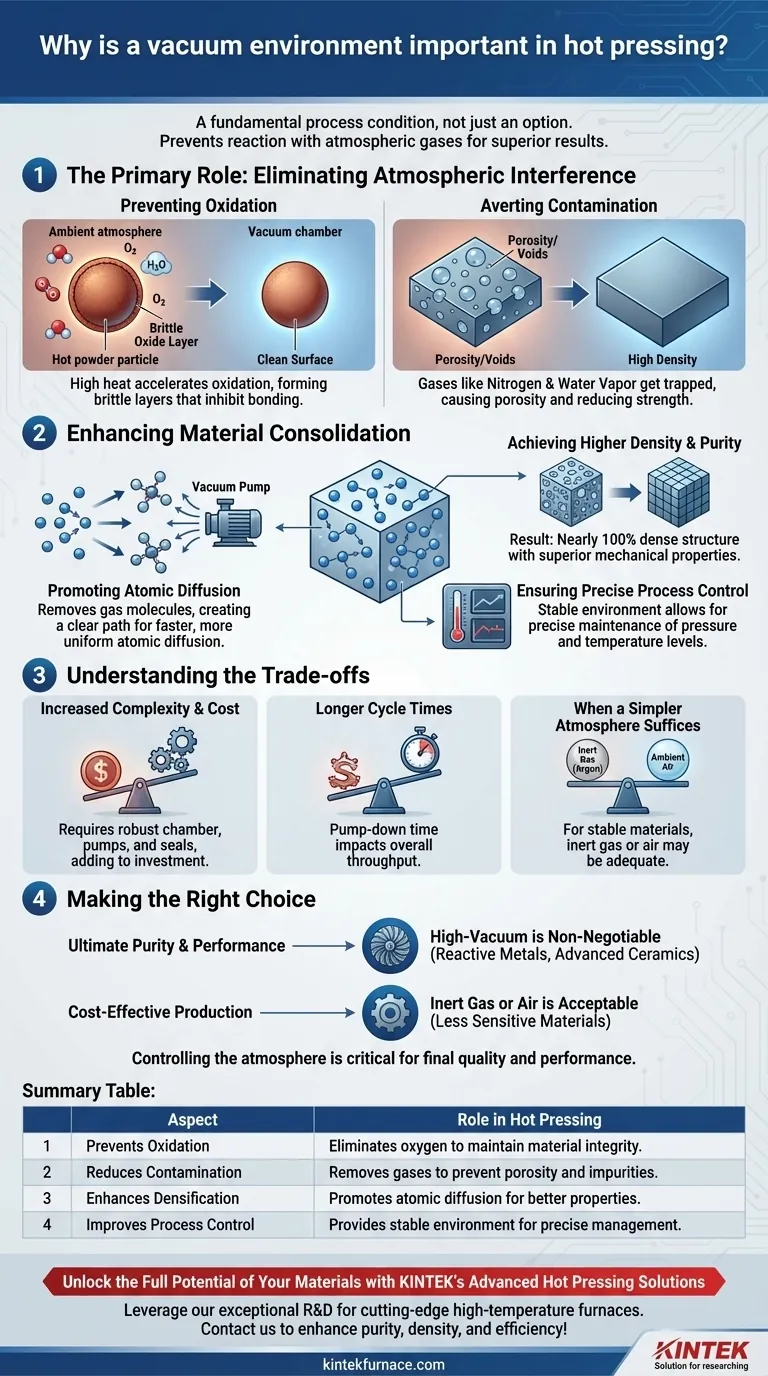

The Primary Role: Eliminating Atmospheric Interference

At the high temperatures required for hot pressing, most materials become highly reactive. The air we breathe—composed of oxygen, nitrogen, and water vapor—becomes a significant source of contamination that can compromise the entire process.

Preventing Oxidation

The most immediate threat is oxidation. High heat acts as a catalyst, dramatically accelerating the reaction between a material and oxygen. This forms brittle oxide layers on the surfaces of the powder particles, which can inhibit proper bonding and create weak points within the final structure.

For reactive metals like titanium or advanced ceramics, this oxidation can completely alter the material's chemical and mechanical properties.

Averting Contamination

Beyond oxygen, other atmospheric gases like nitrogen and water vapor can be equally detrimental. These gases can react with the material to form unwanted nitrides or hydrides, or they can become physically trapped within the consolidated part.

This trapped gas leads to porosity—tiny voids that reduce the final density and serve as stress concentration points, severely degrading the material's strength and performance.

Enhancing the Material Consolidation Process

A vacuum does more than just create a clean environment; it actively improves the physical mechanisms responsible for densification and bonding.

Promoting Atomic Diffusion

Hot pressing works by encouraging atomic diffusion, where atoms from individual powder particles move and bond with each other to form a solid mass. The presence of gas molecules, even inert ones, can physically impede this process.

By removing these gas molecules, a vacuum creates a clear path for atoms to migrate, significantly accelerating diffusion and leading to more effective and uniform densification at lower temperatures or in shorter times.

Achieving Higher Density and Purity

The combined effect of preventing contamination and promoting diffusion is a final product with significantly higher density and purity. With no trapped gases creating pores and no oxide layers inhibiting bonds, the material can consolidate into a nearly 100% dense structure.

This directly translates to superior mechanical properties, such as increased strength, hardness, and fracture toughness.

Ensuring Precise Process Control

A vacuum provides a stable, predictable, and repeatable environment. The control system of a vacuum hot press can maintain precise pressure and temperature levels without the variable interference of atmospheric gases.

This level of control is essential for high-tech applications where even minor deviations in material properties are unacceptable.

Understanding the Trade-offs

While highly beneficial, incorporating a vacuum system is not without its considerations. Understanding these trade-offs is key to making an informed processing decision.

Increased Equipment Complexity and Cost

A vacuum hot press is inherently more complex than an atmospheric furnace. It requires a robust vacuum chamber, seals, and a series of pumps to achieve and maintain low pressure, all of which add to the initial investment and maintenance costs.

Longer Cycle Times

The process of pumping the chamber down to the required vacuum level adds time to each production cycle. This "pump-down" time can impact overall throughput, especially in high-volume manufacturing scenarios.

When a Simpler Atmosphere Suffices

A high vacuum is not always necessary. For materials that are inherently stable and not prone to oxidation, a simpler and more cost-effective approach may be adequate.

This can include pressing in an inert gas atmosphere (like Argon) to displace oxygen or, for very robust materials, even pressing in ambient air.

Making the Right Choice for Your Goal

The decision to use a vacuum, an inert gas, or air depends entirely on the material being processed and the desired properties of the final component.

- If your primary focus is ultimate purity and mechanical performance: A high-vacuum environment is non-negotiable for processing reactive metals, advanced ceramics, or for applications like diffusion bonding.

- If your primary focus is cost-effective production of less sensitive materials: An inert gas atmosphere or even hot pressing in air may provide an acceptable balance of quality and cost.

Ultimately, controlling the processing atmosphere is a critical tool for controlling the final quality and performance of your component.

Summary Table:

| Aspect | Role in Hot Pressing |

|---|---|

| Prevents Oxidation | Eliminates oxygen to avoid brittle oxide layers and maintain material integrity. |

| Reduces Contamination | Removes gases like nitrogen and water vapor to prevent porosity and impurities. |

| Enhances Densification | Promotes atomic diffusion for higher density and better mechanical properties. |

| Improves Process Control | Provides a stable environment for precise temperature and pressure management. |

Unlock the Full Potential of Your Materials with KINTEK's Advanced Hot Pressing Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to meet your unique experimental needs. With strong deep customization capabilities, we ensure precise performance for applications in reactive metals, advanced ceramics, and more.

Contact us today via our contact form to discuss how our vacuum hot pressing technologies can enhance your material purity, density, and overall efficiency—let's achieve superior results together!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing