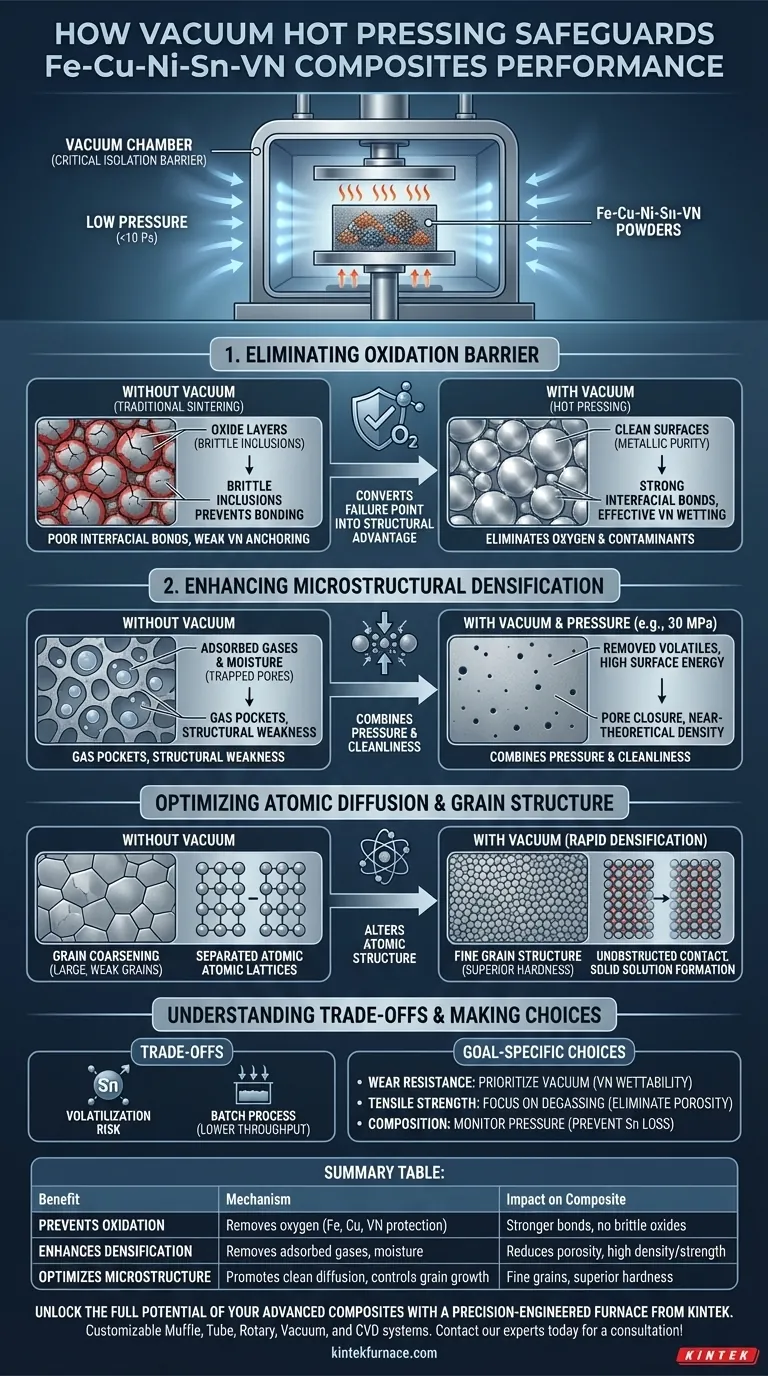

The vacuum environment acts as a critical isolation barrier that is indispensable for processing complex multi-component alloys like Fe-Cu-Ni-Sn-VN. It safeguards performance primarily by preventing the oxidation of metallic powders and removing adsorbed gases during the high-temperature sintering phase. This creates chemically clean surfaces that allow for optimal atomic diffusion, resulting in a dense, high-strength composite with superior wear resistance.

By eliminating oxygen and volatile contaminants, the vacuum hot press furnace converts a potential metallurgical failure point—interfacial oxidation—into a structural advantage. This ensures that the mechanical properties of the final composite are defined by the material's intrinsic strength, rather than by defects or brittle oxide inclusions.

Eliminating the Oxidation Barrier

The primary threat to the performance of Fe-Cu-Ni-Sn-VN composites is the formation of oxide layers at high temperatures.

Protecting Reactive Elements

Iron (Fe) and Copper (Cu) are highly susceptible to oxidation when heated. Even trace amounts of oxygen can form brittle oxide films on powder surfaces.

These films act as a physical barrier, preventing the metal particles from bonding essentially. The vacuum environment strips away this risk, maintaining the metallic purity required for sintering.

Preserving Hard Phase Integrity

Vanadium Nitride (VN) particles provide wear resistance, but they must be firmly anchored in the metal matrix to function.

If the matrix surrounding the VN particles oxidizes, the interfacial bond weakens. Under stress, poorly bonded VN particles will simply pull out of the material rather than resisting wear. A vacuum ensures the matrix wets the VN particles effectively.

Enhancing Microstructural Densification

Achieving high density is critical for mechanical performance. The vacuum environment works in tandem with mechanical pressure to close internal voids.

Removal of Adsorbed Gases

Metal powders naturally adsorb gases and moisture on their surfaces during storage. If these gases are not removed, they become trapped inside the material as pores close.

The low-pressure environment (often below 10 Pa) actively extracts these volatiles before the material densifies. This prevents gas pockets that would otherwise lead to porosity and structural weakness.

Promoting Pore Closure

Clean, oxide-free surfaces have higher surface energy, which drives the sintering process.

When combined with the external pressure of the hot press (e.g., 30 MPa), the clean particle boundaries collapse and weld together more easily. This results in a material with near-theoretical density and minimal microscopic defects.

Optimizing Atomic Diffusion and Grain Structure

The vacuum hot press does not just glue particles together; it alters the atomic structure of the composite.

Facilitating Solid Solution Formation

For the composite to achieve high strength, elements like Nickel (Ni) and Tin (Sn) must diffuse into the Iron and Copper lattice.

The vacuum environment ensures there are no oxide barriers between these distinct metallic phases. This unobstructed contact allows for effective atomic diffusion, creating strong solid solutions that reinforce the matrix.

Controlling Grain Growth

Traditional sintering often requires long heating times which leads to grain coarsening (large, weak grains).

Vacuum hot pressing combines heating and pressure in a single, efficient step. This rapid densification preserves fine grain structures (often in the nanometer range), which significantly enhances hardness and strength compared to the coarse grains found in conventional sintering.

Understanding the Trade-offs

While vacuum hot pressing is superior for performance, there are specific constraints you must manage to ensure success.

Risk of Element Volatilization

While a vacuum is good for preventing oxidation, it can be problematic for elements with high vapor pressures.

Tin (Sn) creates a specific challenge here. If the vacuum is too high or the temperature unchecked, Sn may begin to vaporize (evaporate) out of the alloy before it can diffuse. This alters the chemical composition and can leave behind micropores.

Equipment and Throughput Limitations

Vacuum hot pressing is inherently a batch process.

Unlike continuous belt sintering used for simpler parts, this method creates a bottleneck in production speed. It is a trade-off where you sacrifice manufacturing volume for exceptional material quality and density.

Making the Right Choice for Your Goal

The vacuum environment is a tool. How you use it depends on the specific performance metric you need to maximize in your Fe-Cu-Ni-Sn-VN composite.

- If your primary focus is Wear Resistance: Prioritize the vacuum level to ensure maximum wettability of the VN particles, preventing particle pull-out during friction.

- If your primary focus is Tensile Strength: Focus on the degassing phase to eliminate all porosity, ensuring the matrix is a solid, continuous block without stress concentrators.

- If your primary focus is Compositional Accuracy: Monitor the vacuum pressure carefully during the temperature ramp to prevent the volatilization of Tin (Sn).

Ultimately, the vacuum environment transforms the sintering process from a simple heating cycle into a precision chemical control mechanism, unlocking the full potential of complex alloy systems.

Summary Table:

| Benefit | Mechanism | Impact on Composite |

|---|---|---|

| Prevents Oxidation | Removes oxygen to protect reactive elements (Fe, Cu) and VN particles. | Stronger interfacial bonds, eliminates brittle oxide inclusions. |

| Enhances Densification | Removes adsorbed gases and moisture from powder surfaces. | Reduces porosity, achieves near-theoretical density for high strength. |

| Optimizes Microstructure | Promotes clean atomic diffusion and controls grain growth. | Fine grain structure for superior hardness and mechanical properties. |

Unlock the full potential of your advanced composites with a precision-engineered furnace from KINTEK.

Are you developing high-performance materials like Fe-Cu-Ni-Sn-VN composites? The right equipment is critical for achieving the superior density, strength, and wear resistance your applications demand. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, including vacuum hot press furnaces, all customizable for your unique material processing needs.

Let's discuss how our solutions can safeguard your material's performance. Contact our experts today for a consultation!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What core functions do high-purity graphite molds perform during the SPS of LaFeO3? Optimize Your Sintering Process

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What role do graphite molds play in the vacuum hot press sintering process of IZO targets? Ensuring Purity and Density

- What role does a hot-press sintering furnace play in Y2O3-YAM composite ceramics? Achieve 100% Density & Control Grains

- What is the function of an infrared pyrometer in the SPS process of Ti-6Al-4Zr-4Nb? Precision Phase Control Explained

- What are the disadvantages of hot pressing compared to cold compacting and sintering? Higher Costs and Lower Production Rates

- How does a precision pressure control system assist in material formation during Eutectic Bonding?